Double bundle conductor spacer mounting auxiliary rod

A technology of double-split conductors and installation assistance, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient length adjustment, heavy physical exertion of operators, and loose fixation of fixed ropes, etc. Ease of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

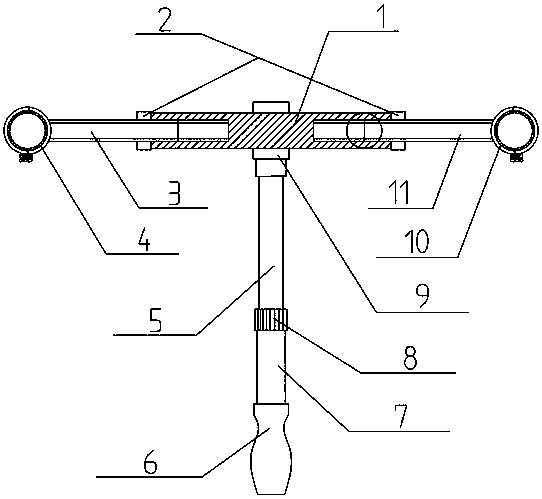

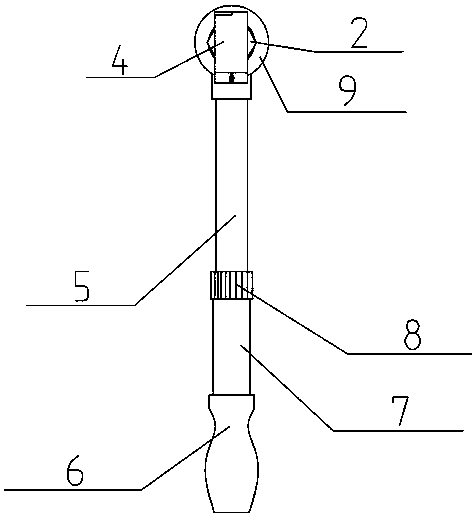

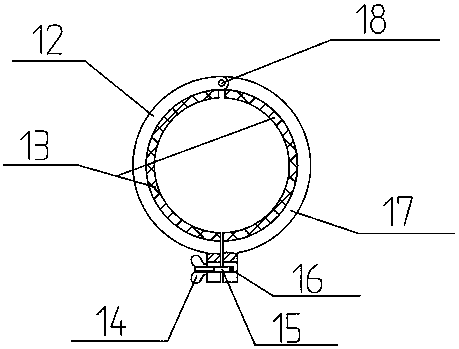

[0019] as attached figure 1 , figure 2 , image 3 Shown a kind of double-split wire spacer installation auxiliary bar, comprises cross arm 1, left lead screw 3, left fixing ring 4, right lead screw 11, right fixing ring 10, connecting sleeve 9 and telescopic rod, described cross arm 1 is arranged horizontally on the upper part, the cross arm 1 is a cylindrical structure, the left and right ends of the cross arm 1 are provided with threaded holes, and the threaded holes at both ends are connected with the left lead screw 3 and the right lead screw 11; the left lead screw 3 is set on the left side of the cross arm 1, the right screw 11 is set on the right side of the cross arm 1, the left screw 3 and the right screw 11 have the same structure, and the middle part is equipped with a screw lock nut 2; Fixed ring 4 is arranged on the left end of left leading screw 3, and left fixed ring 4 is made of fixed half ring 17, moving half ring 12, bushing 13, rotating shaft 16, locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com