Rotor for an impact crusher

An impact crusher and rotor technology, applied in grain processing and other directions, can solve the problems of product quality deterioration, prolonged shutdown of the impact crusher, time-consuming replacement of the impact plate, etc., and achieve the effect of reducing the downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

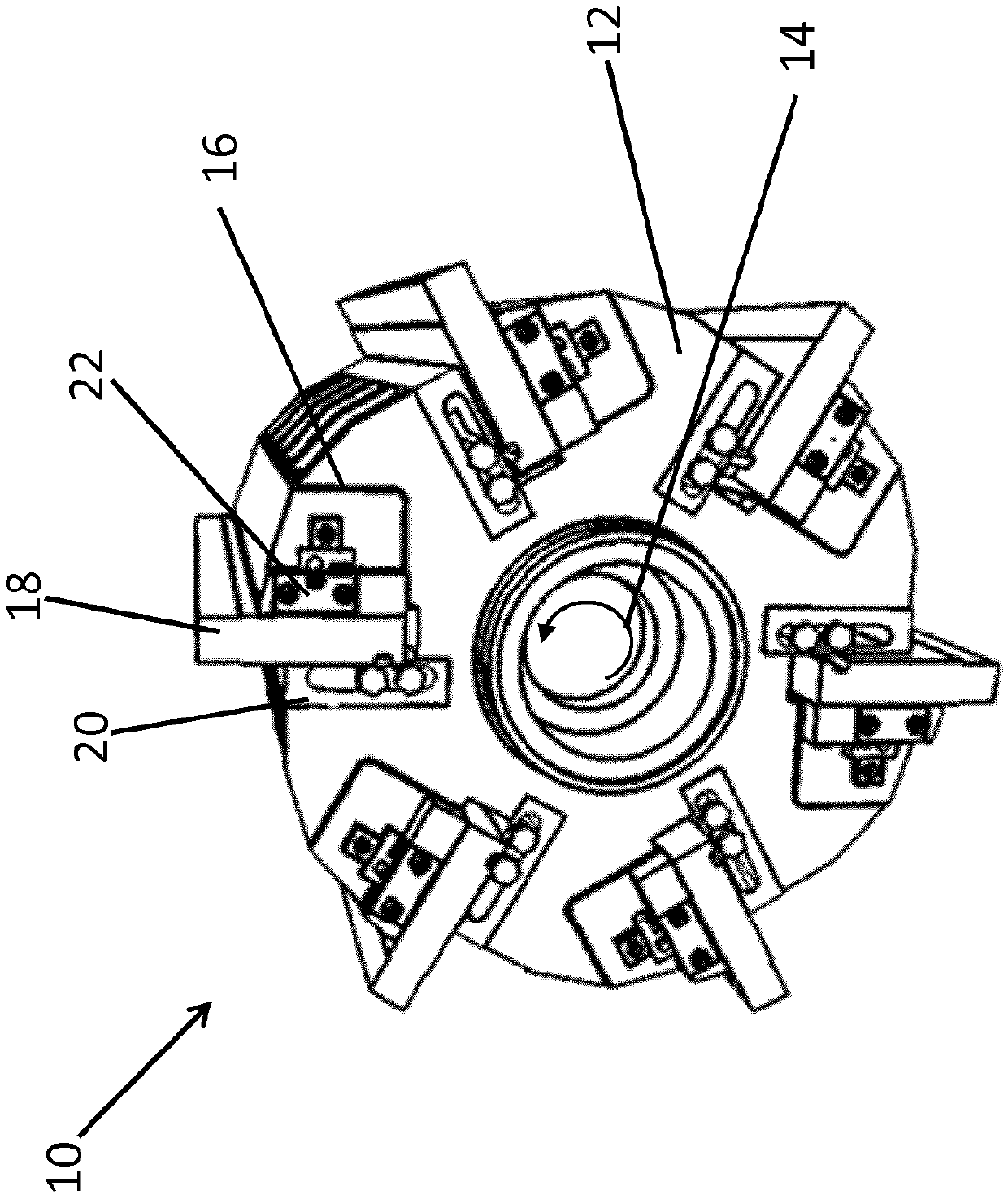

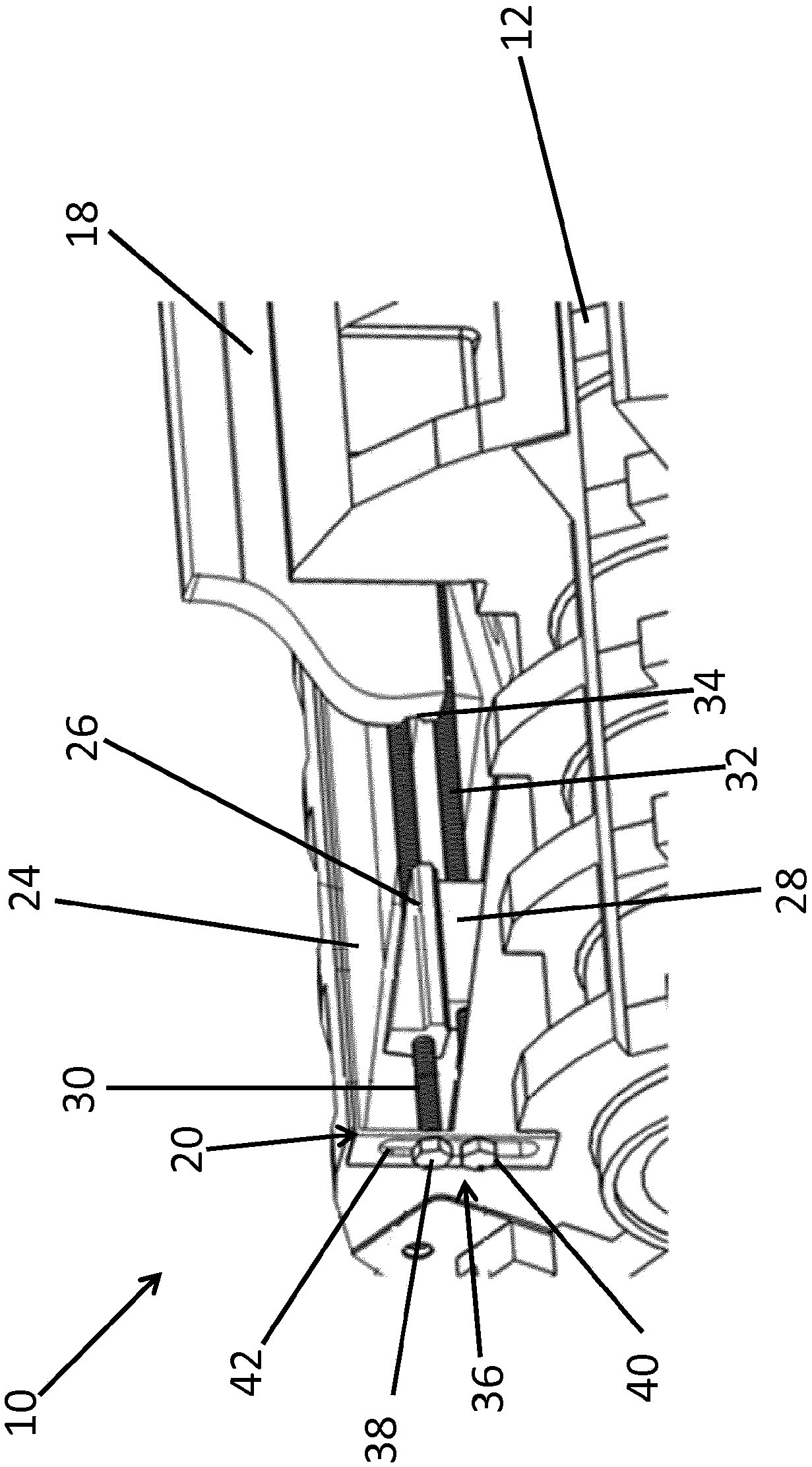

[0036] figure 1 Shown is a rotor 10 of an impact crusher for crushing limestone, marl, clay, crushed stone or similar mineral material. The rotor 10 comprises a generally cylindrical crushing roll body 12 having a central axial bore 14 to receive a shaft (not shown) for driving the crushing roll body. During operation of the impact crusher, the rotor 10 rotates in the direction of the arrow, wherein the striking plate 18, for example, rotates in the opposite direction with another rotor ( figure 1 (not shown) or the striking plate 18 interacts with a striking element (not shown) arranged on the side of the rotor 10 .

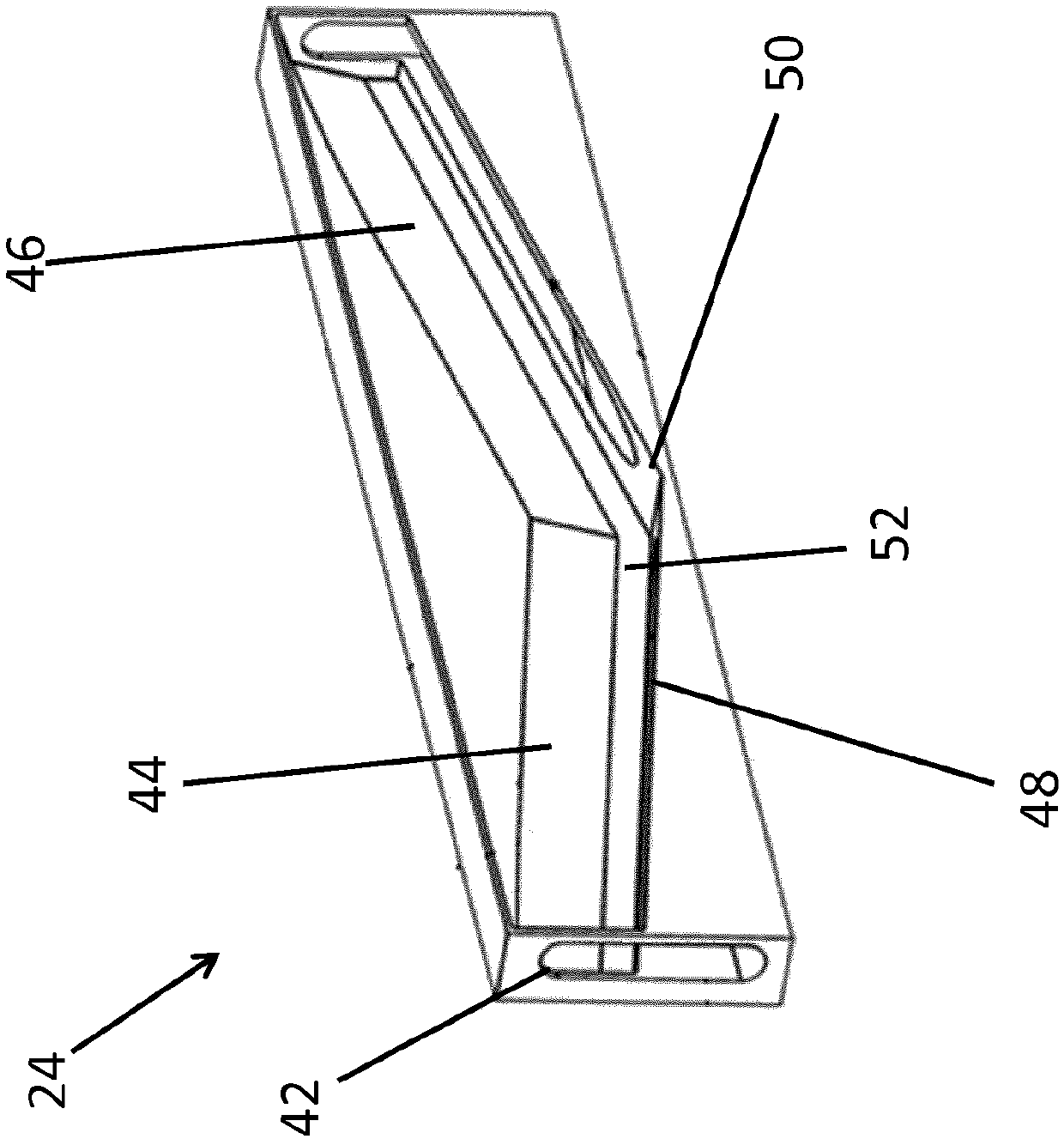

[0037] The crushing roller body 12 has on its outer circumference six recesses 16 extending in the axial direction, and wherein a striking plate 18 and a holding device 20 are arranged in each of the six recesses 16 . The substantially plate-shaped striker plates 18 extend over the entire length of the crushing roll body 12 in the axial direction, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com