Disassemble laser cutting knife rest structure

A laser cutting and laser cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to rotate and adjust, and the fixed structure of the knife holder cannot be disassembled and separated, so as to enhance the flexibility of use, Easy to fix and remove, easy to remove and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

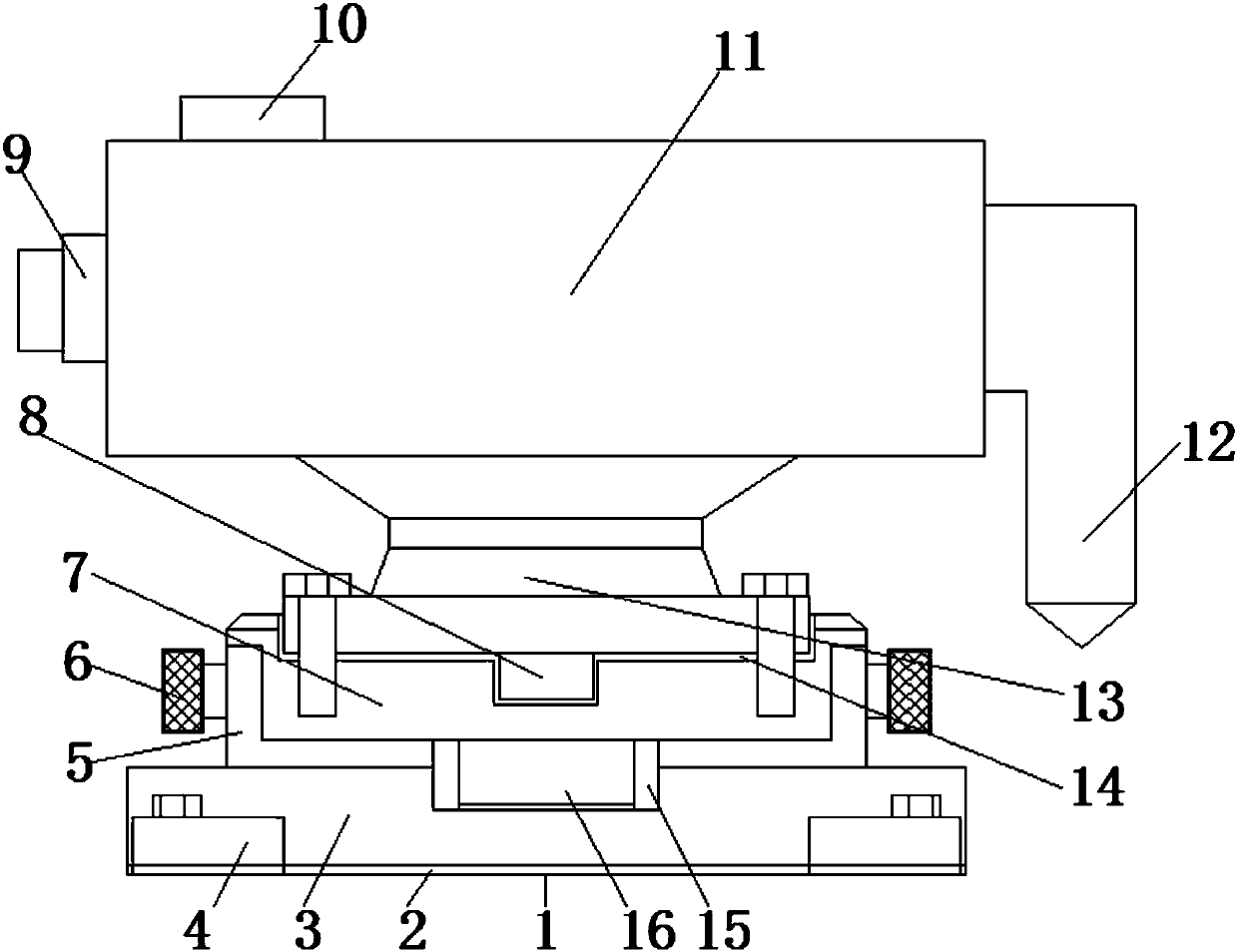

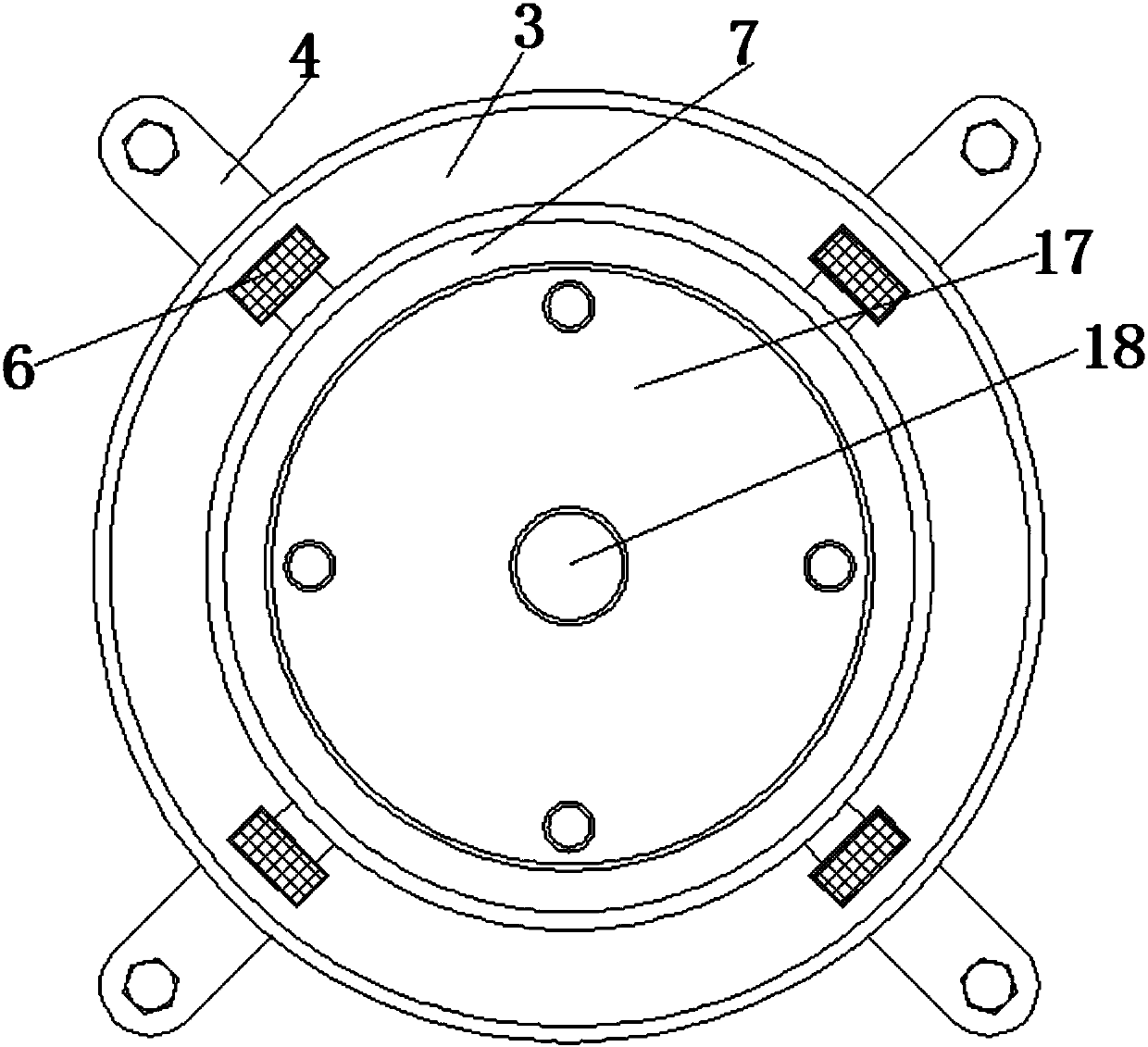

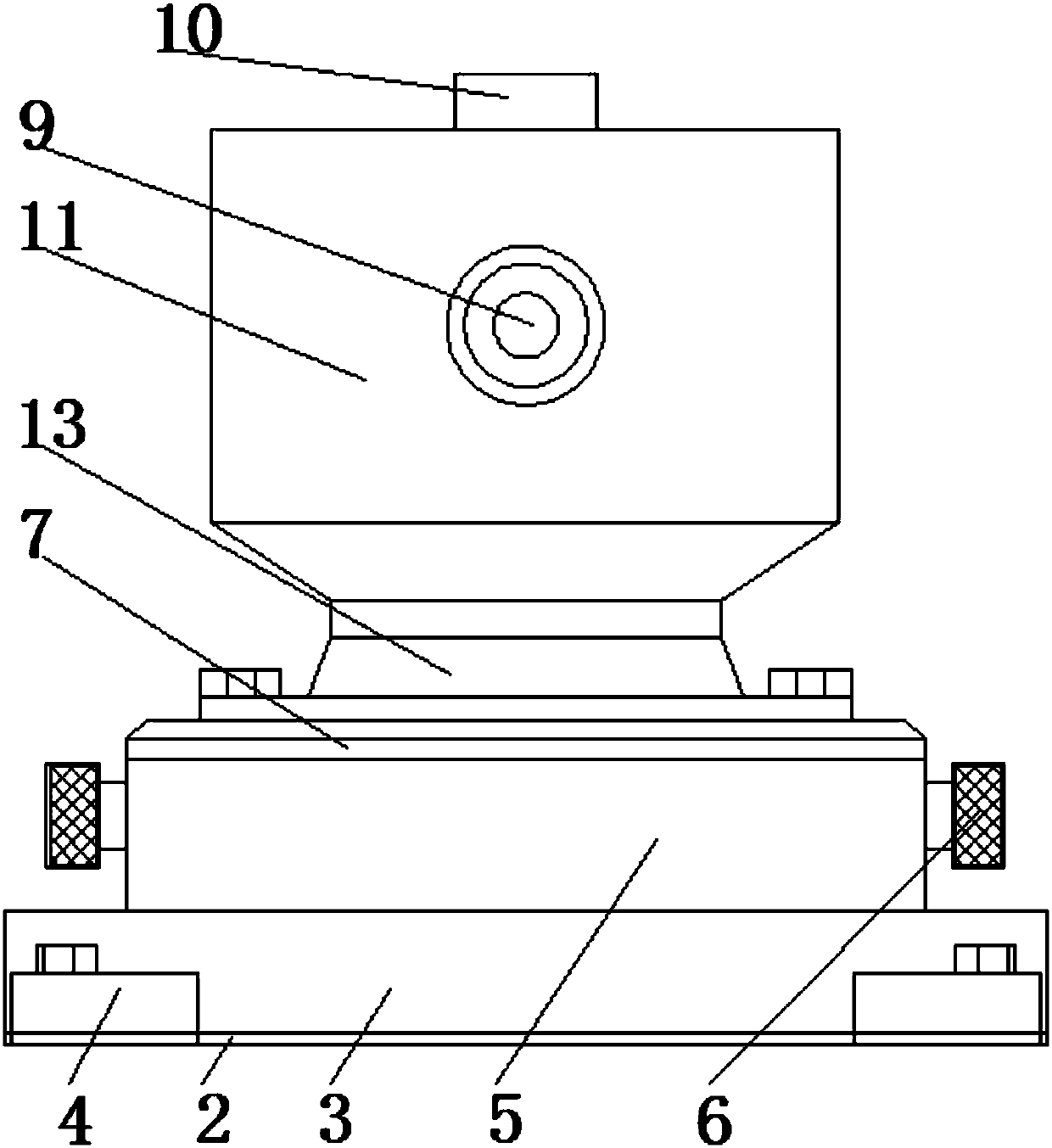

[0022] as attached figure 1 to attach Figure 4 Shown:

[0023] The present invention provides a detachable laser cutting tool holder structure, which includes a device body 1, a protective fixed pad 2, a fixed base plate 3, a fixed raised bar 4, a fixed sleeve 5, an adjustment knob 6, a rotating fixed plate 7, a raised Guide column 8, power socket 9, switch button 10, laser cutting machine 11, laser cutting head 12, connection base 13, spacer rubber layer 14, bearing 15, fixed raised column 16, limit installation groove 17 and guide fixing hole 18. The bottom of the device body 1 is provided with a fixed substrate 3, and the bottom surface of the fixed substrate 3 is provided with a protective fixed pad 2; the outer circular array of the bottom circumference of the fixed substrate 3 has four fixed raised strips 4, and the fixed raised strips 4. The outer ends are all provided with installation holes; the center of the top of the fixed base plate 3 is provided with a fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com