Pipeline flange plate butting device for petroleum refining

A technology for docking devices and pipes, which can be used in hand-held tools, manufacturing tools, etc., and can solve the problems of inconvenient docking, time-consuming and laborious, and easy-to-move flanges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

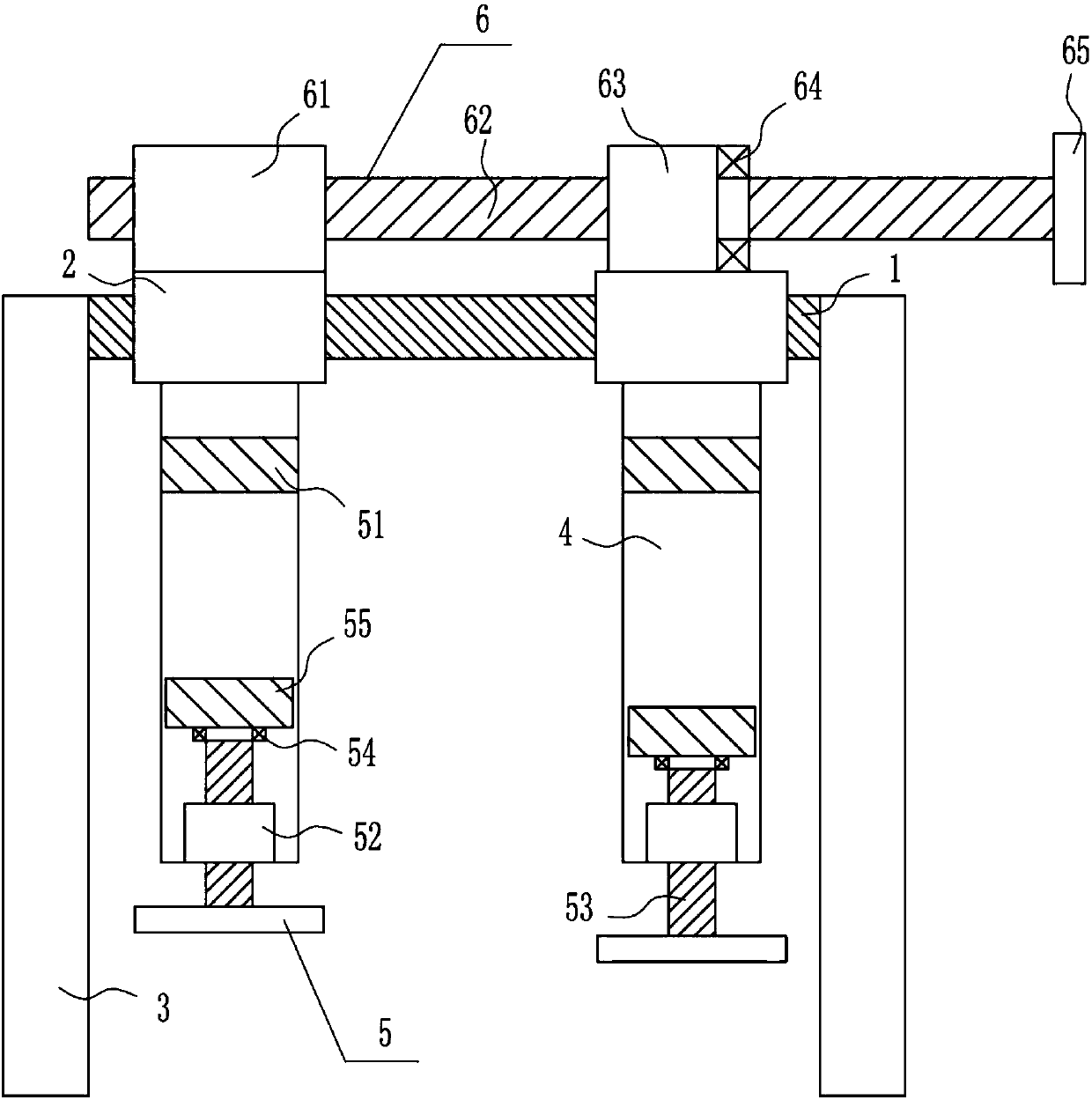

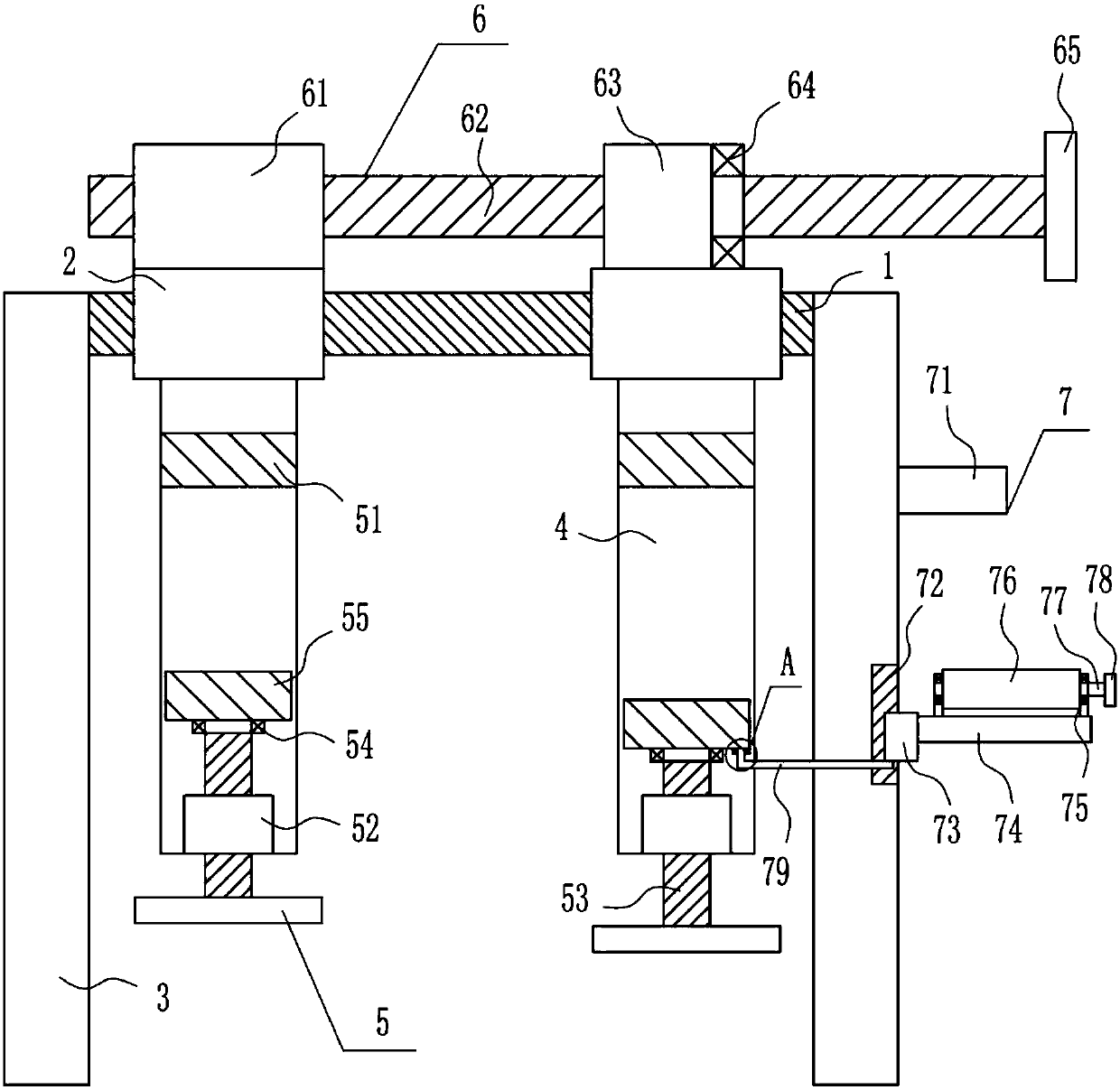

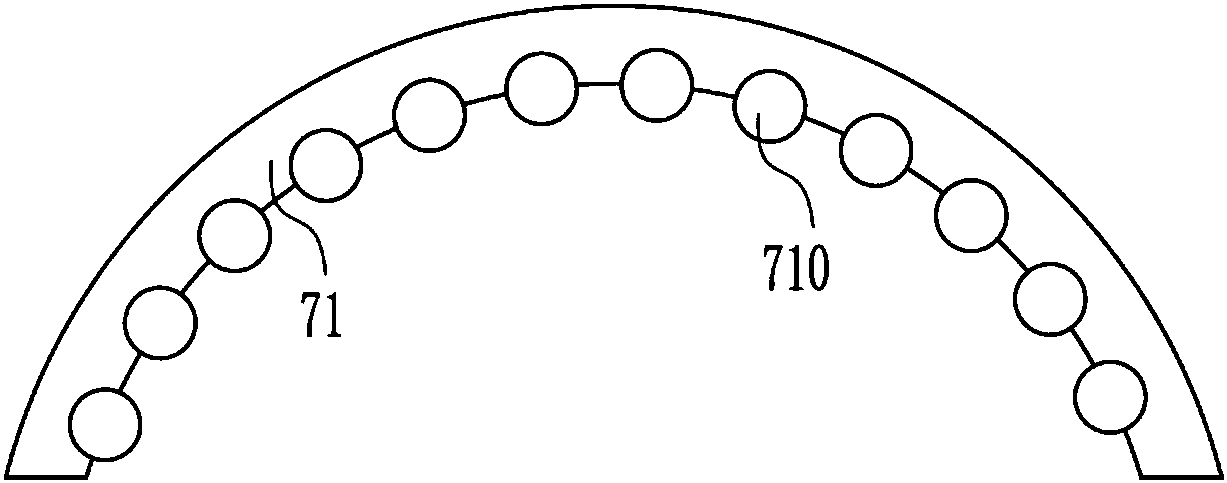

[0030] A pipe flange butt joint device for petroleum refining, such as Figure 1-6 As shown, it includes a first slide rail 1, a first slide block 2, a leg 3, a riser 4, a fixing device 5 and a moving device 6, and the first slide rail 1 is provided with two first slide blocks 2, and the first slide rail 1 is provided with two first slide blocks 2. A slide block 2 is slidingly matched with the first slide rail 1, and a moving device 6 is arranged between the tops of the two first slide blocks 2. Legs 3 are installed on the left side and the right side of the first slide rail 1, and the first A riser 4 is installed in the middle of the bottom of the slider 2, and a fixing device 5 is provided on the front side of the riser 4.

Embodiment 2

[0032] A pipe flange butt joint device for petroleum refining, such as Figure 1-6As shown, it includes a first slide rail 1, a first slide block 2, a leg 3, a riser 4, a fixing device 5 and a moving device 6, and the first slide rail 1 is provided with two first slide blocks 2, and the first slide rail 1 is provided with two first slide blocks 2. A slide block 2 is slidingly matched with the first slide rail 1, and a moving device 6 is arranged between the tops of the two first slide blocks 2. Legs 3 are installed on the left side and the right side of the first slide rail 1, and the first A riser 4 is installed in the middle of the bottom of the slider 2, and a fixing device 5 is provided on the front side of the riser 4.

[0033] The fixing device 5 includes a fixed block 51, a first nut 52, a first screw rod 53, a first bearing seat 54 and an arc block 55, the upper part of the front side of the riser 4 is equipped with a fixed block 51, and the lower part of the front sid...

Embodiment 3

[0035] A pipe flange butt joint device for petroleum refining, such as Figure 1-6 As shown, it includes a first slide rail 1, a first slide block 2, a leg 3, a riser 4, a fixing device 5 and a moving device 6, and the first slide rail 1 is provided with two first slide blocks 2, and the first slide rail 1 is provided with two first slide blocks 2. A slide block 2 is slidingly matched with the first slide rail 1, and a moving device 6 is arranged between the tops of the two first slide blocks 2. Legs 3 are installed on the left side and the right side of the first slide rail 1, and the first A riser 4 is installed in the middle of the bottom of the slider 2, and a fixing device 5 is provided on the front side of the riser 4.

[0036] The fixing device 5 includes a fixed block 51, a first nut 52, a first screw rod 53, a first bearing seat 54 and an arc block 55, the upper part of the front side of the riser 4 is equipped with a fixed block 51, and the lower part of the front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com