Paper mold auxiliary molding and trimming equipment

A technology for auxiliary forming and forming equipment, applied in the direction of cardboard articles, metal processing, etc., can solve the problems that are unfavorable to the large-scale production of production enterprises, modern and standardized production, low degree of automation, and cannot further improve the production efficiency of paper molds. The effects of production stability, avoidance of pick-and-place mistakes, and improvement of practicability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

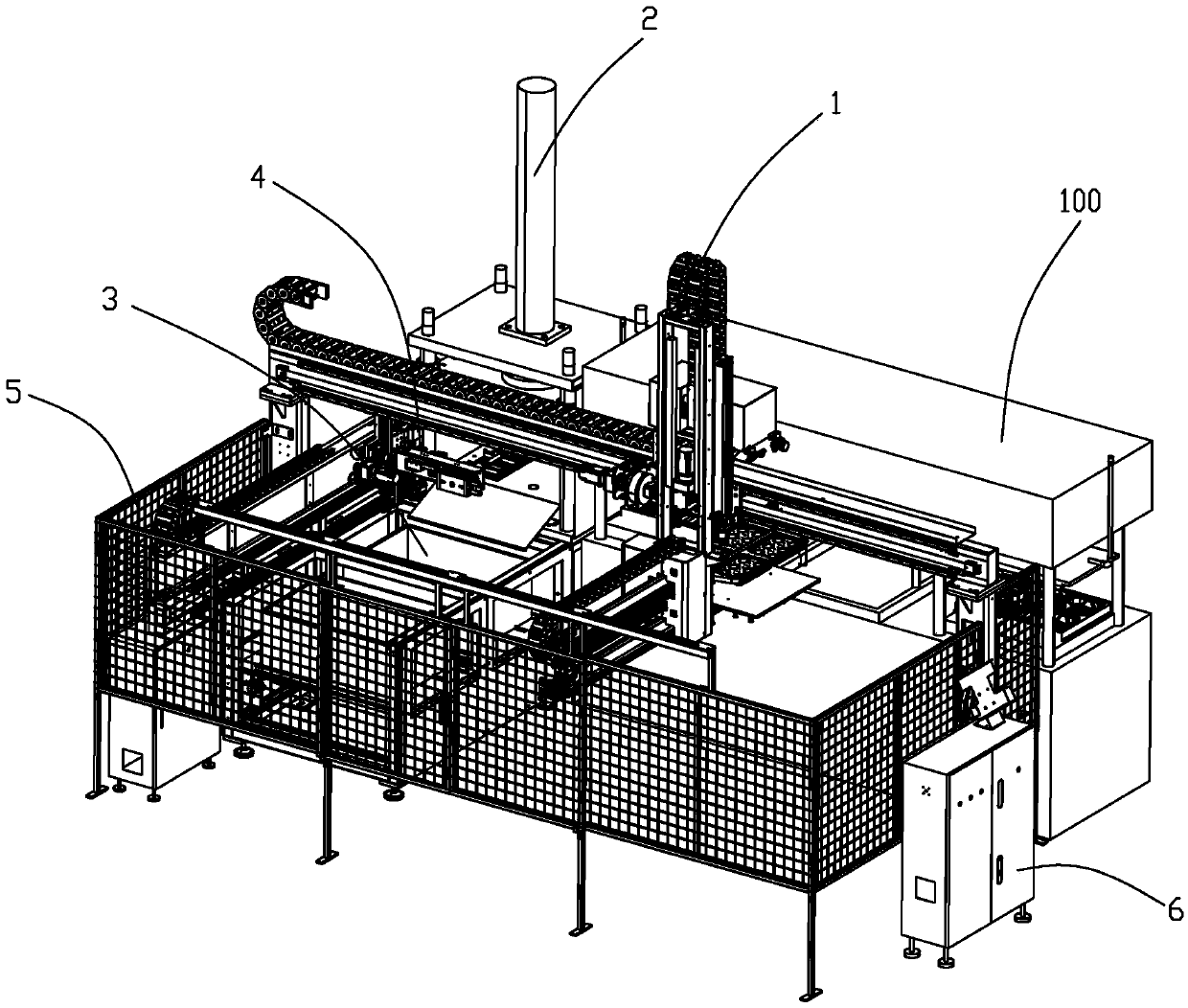

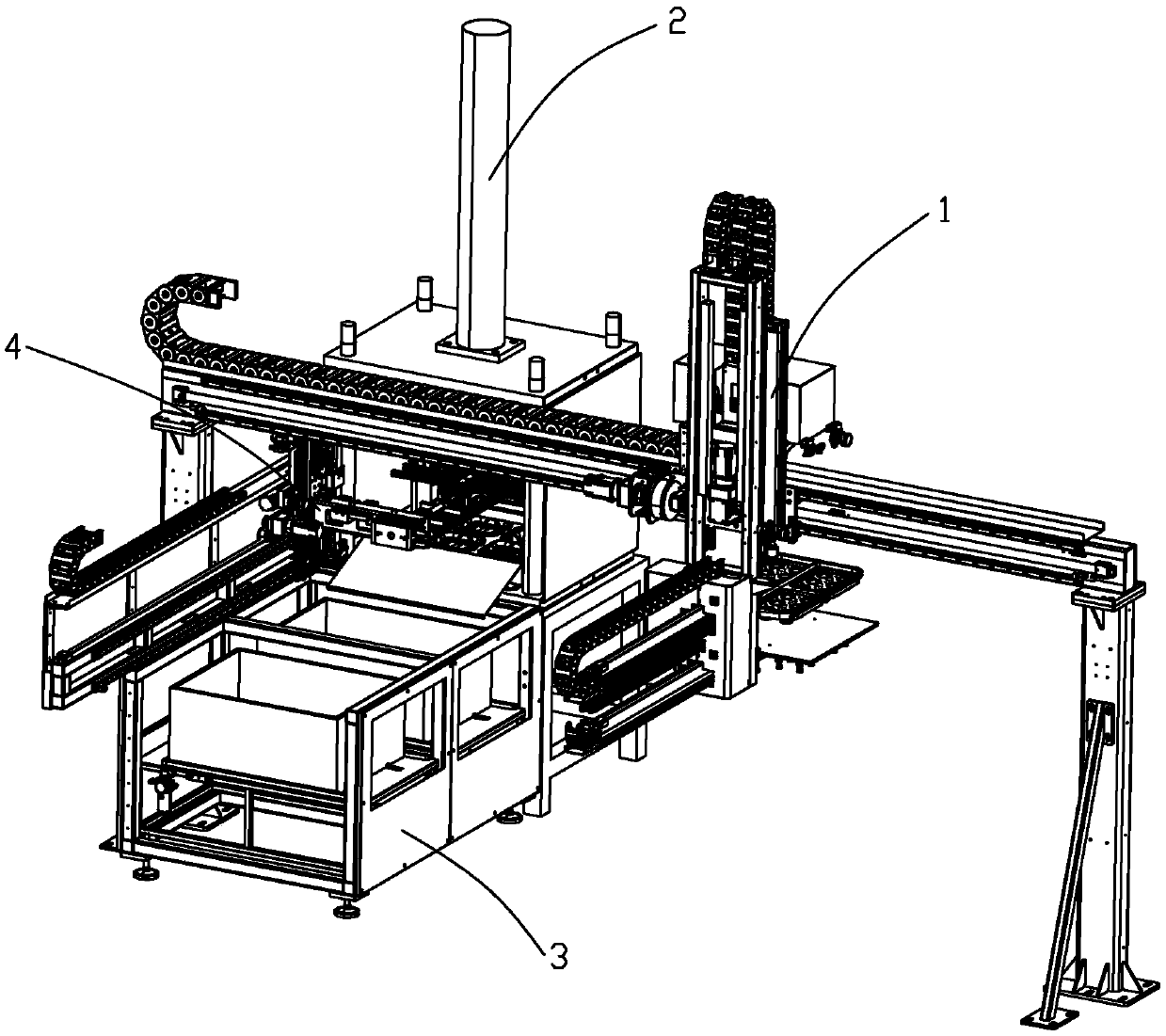

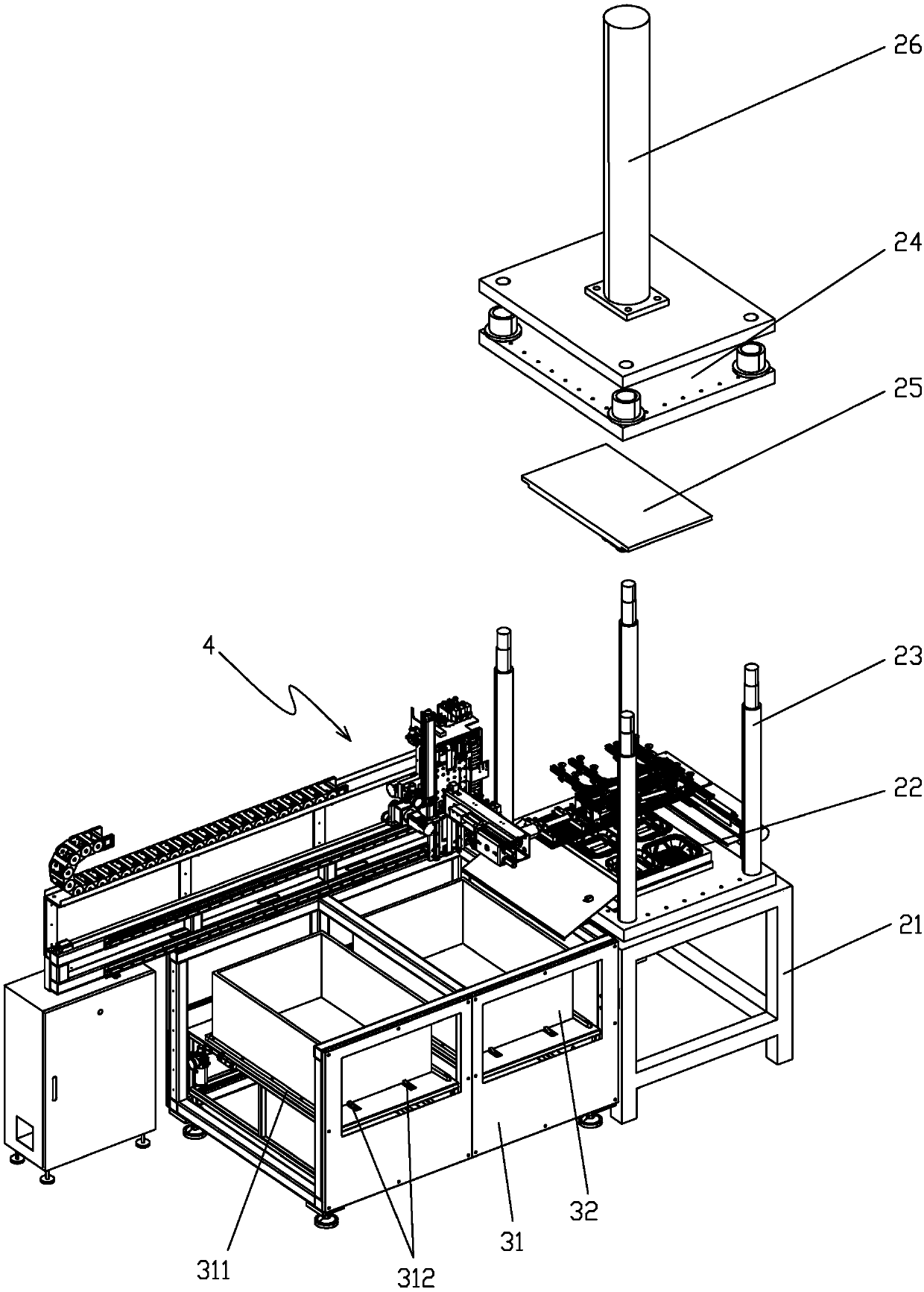

[0055] Such as Figure 1-9 As shown, it is applied to auxiliary forming paper mold and trimming equipment, including auxiliary forming pick-and-place device 1, paper mold trimming device 2, loading device 3, pick-up device 4, protective cover 5 and distribution box 6.

[0056] Specifically, the auxiliary forming pick-and-place device 1 is arranged on one side of the paper mold forming equipment 100, and is used for sucking the preliminary formed wet paper mold from the wet paper mold forming station located on the paper mold forming equipment 100, and will absorb The wet paper mold is placed on the wet paper mold drying station on the paper mold forming equipment 100, and when the wet paper mold is dried to form a dry paper mold, it is used to take out the dry paper mold. The paper mold trimming device 2 is located on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com