Bucking winder

A wire winder and buckle-type technology, which is applied in the field of buckle-type wire winders, can solve the problems of cumbersome operation, entanglement of various wires, and easy scattering of stick-type wire winders, so as to achieve easy wire taking operation, Avoid wire entanglement and facilitate winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

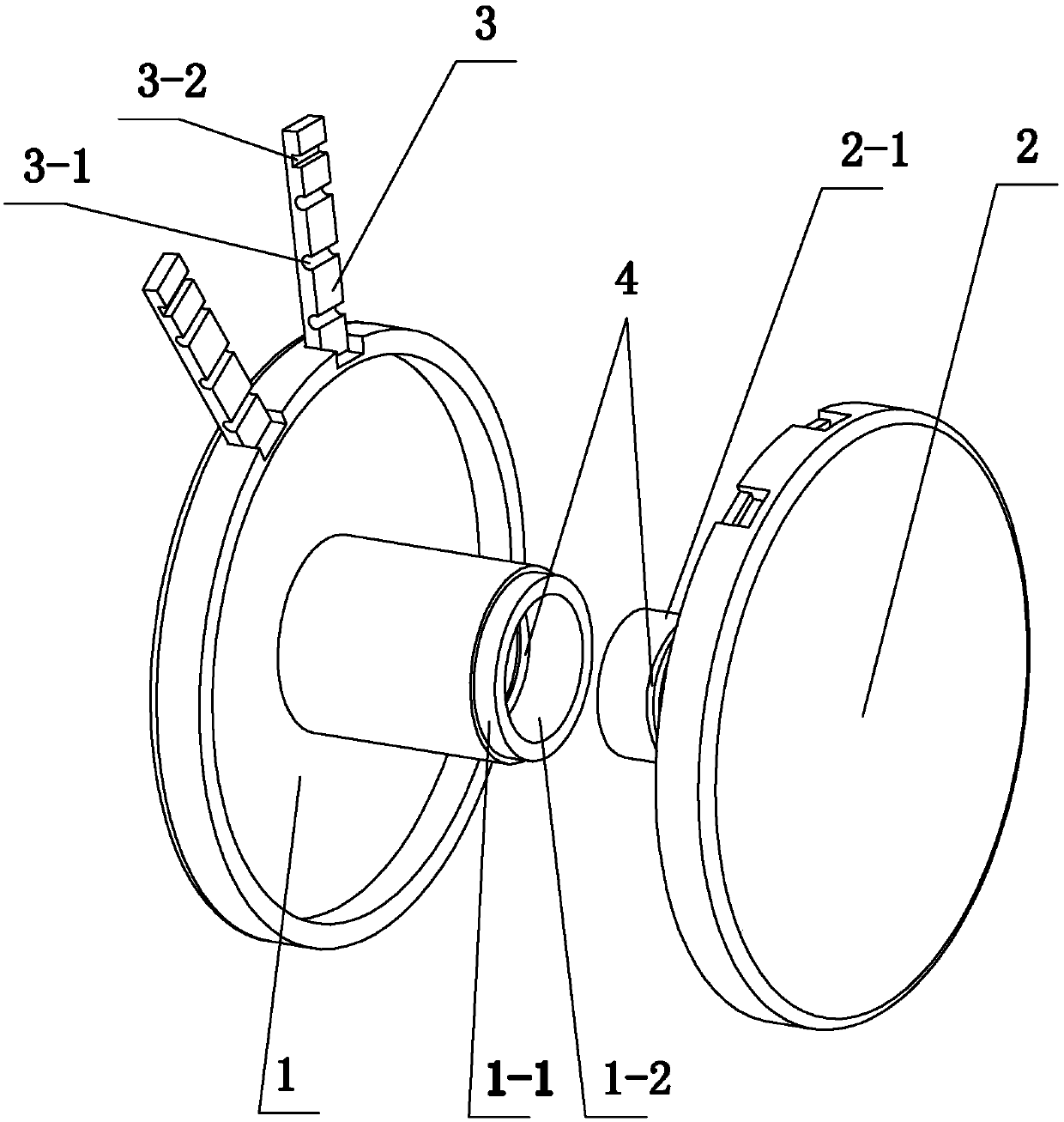

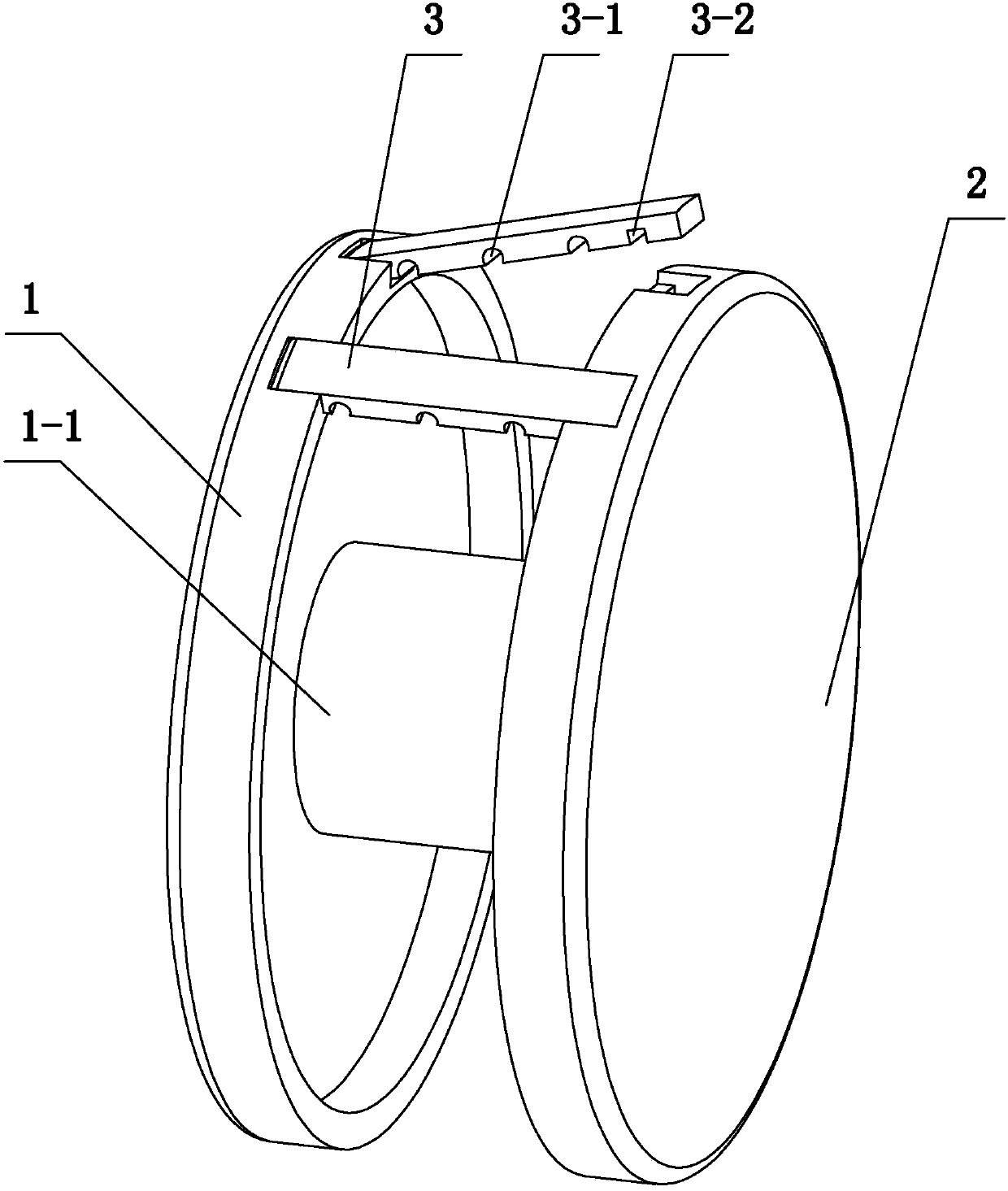

[0019] A buckle-type wire winder described in this embodiment, its main body is composed of an upper cover body 1, a lower cover body 2, and a connecting arm 3, as shown in the attached figure 1 shown.

[0020] The inner middle part of the upper cover body 1 is provided with a winding post 1-1, and the winding post 1-1 has an axial through hole 1-2, and the outer wall of the winding post 1-1 is covered with a frosted rubber sleeve; A connecting column 2-1 matching the through hole 1-2 is provided on the inner side, and a detachable buckle structure 4 corresponding to the inner side of the through hole 1-2 and the outer side of the connecting column 2-1 is provided, and the buckle structure 4 of the embodiment adopts a corresponding setting The arc-shaped flange and the arc-shaped groove on the inner side of the through hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com