Production die of lantern skeleton and use method of production die

A technology for molds and lanterns, applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient carrying, inability to fold, and monotonous shape, achieve convenient transfer and storage, improve aesthetic performance, and simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

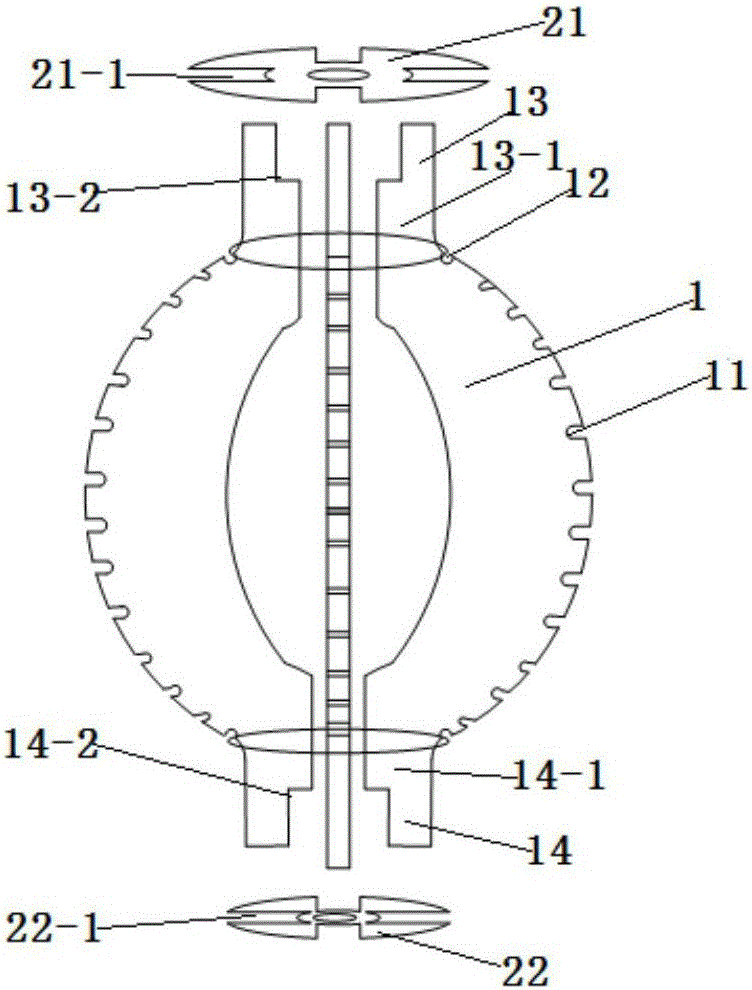

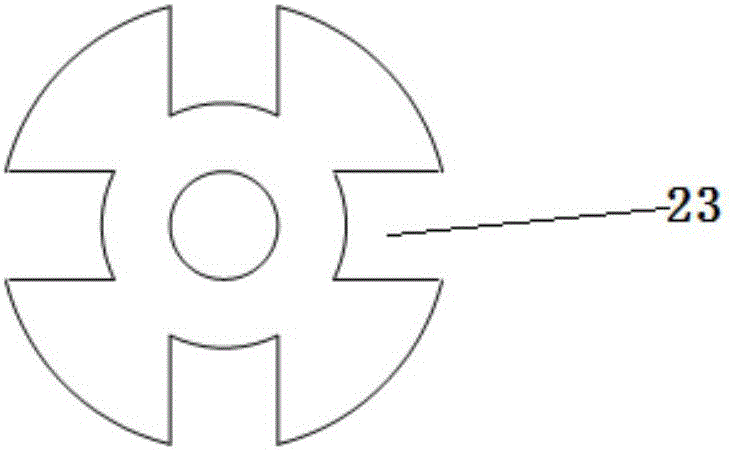

[0037] Such as figure 1 and image 3As shown, the production mold of a lantern skeleton in this embodiment includes a mould, and the mold includes a connecting piece and several bone pieces 1, and the connecting piece includes an upper connecting piece 21 and a lower connecting piece 22, and the upper connecting piece 21 and the lower connecting piece The center of the connector 22 is provided with a through hole, the outer diameter of the upper connector 21 is greater than the outer diameter of the lower connector 22, the periphery of the upper connector 21 is provided with an upper bayonet 21-1, and the outer diameter of the lower connector 22 The lower bayonet 22-1 is arranged on the periphery, the number of the upper bayonet 21-1 and the lower bayonet 22-1 is the same as the number of the bone piece 1, and the upper connector 21 and the lower connector 22 are respectively detachably connected with the bone piece 1 , so that the mold structure can be disassembled, so that ...

Embodiment 2

[0039] The production mold of a lantern skeleton in this embodiment is basically the same as that of Embodiment 1, except that in this embodiment, the number of bone pieces 1 is six, and the same row of grooves on adjacent bone pieces 1 The inclination angle of 11 is 14°, and the lantern made by this structure is stable in structure, and the skeleton bar used is the shortest, so that the cost of manufacture is low and the economic benefit is good.

Embodiment 3

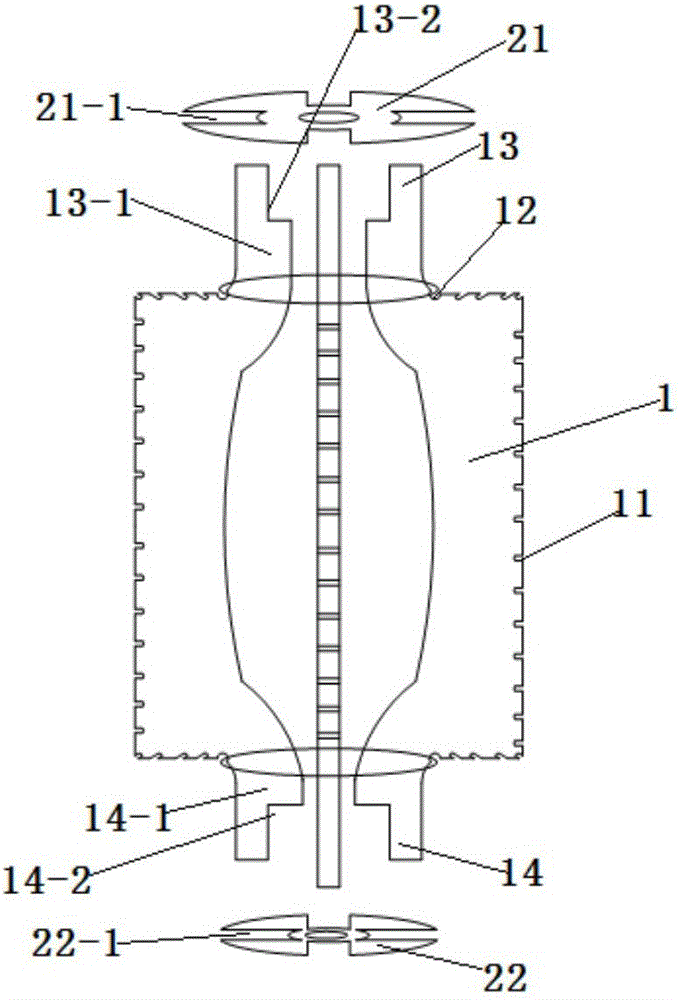

[0041] Such as figure 2 As shown, a production mold of a lantern skeleton in this embodiment includes a mould, and the mold includes connectors and several bone pieces 1, and the connectors include upper connectors 21 and lower connectors 22, and the upper connectors 21 The inner diameter of the inner circle is the same as that of the lower connector 22, the outer diameter of the upper connector 21 is greater than the outer diameter of the lower connector 22, the periphery of the upper connector 21 is provided with an upper bayonet 21-1, and the lower connector 21 The periphery of 22 is provided with lower bayonet 22-1, and the number of upper bayonet 21-1 and lower bayonet 22-1 is the same as the number of bone piece 1, and upper connector 21 and lower connector 22 can be connected with bone piece 1 respectively. Disassemble the connection, the protruding outer edge of the bone piece 1 is provided with several grooves 11, the inclination angle of the grooves on the same row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com