Novel single-side self-adhesive enameled replacement lead

A transposition wire, self-adhesive technology, applied in the direction of conductors, conductive connections, insulated conductors, etc., can solve the problems affecting the heat dissipation performance of transposition wire windings, and achieve the effect of maintaining mechanical strength and increasing heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

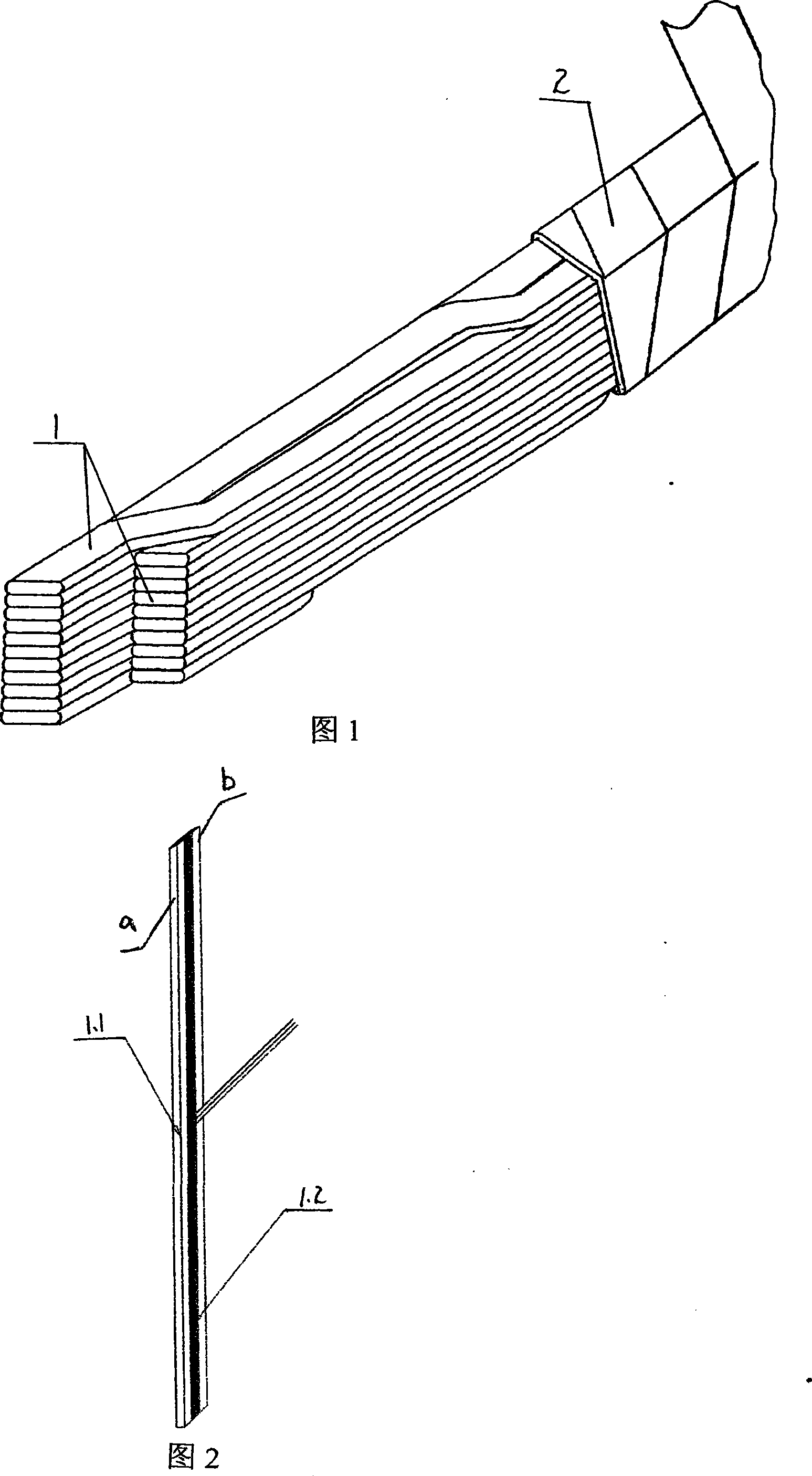

[0012] Referring to Fig. 1, the novel unilateral self-adhesive enamelled transposition wire of the present invention is composed of enamelled copper flat wires 1 with a certain number (generally 7 to 63) into two columns in which wide surfaces are in contact with each other. On the top and bottom of the two rows of enamelled copper flat wires 1, do the same steering transposition along the narrow surface, and press on the wide surface b of the enamelled copper flat wire single wire 1.1 where the wide surfaces of the two rows of enamelled copper flat wires are in contact with each other. Self-adhesive epoxy resin paint 1.2 is coated with technical requirements thickness, as shown in Figure 2; and self-adhesive epoxy resin paint is not coated on the narrow surface a of the enamelled copper flat wire single wire. And use electrical insulating paper tape or mesh belt 2 as winding wires for multi-layer continuous tight or single-layer wrapping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com