Refining method of hexanitrohexaaza-isowurtzitane based subject-object explosive crystal

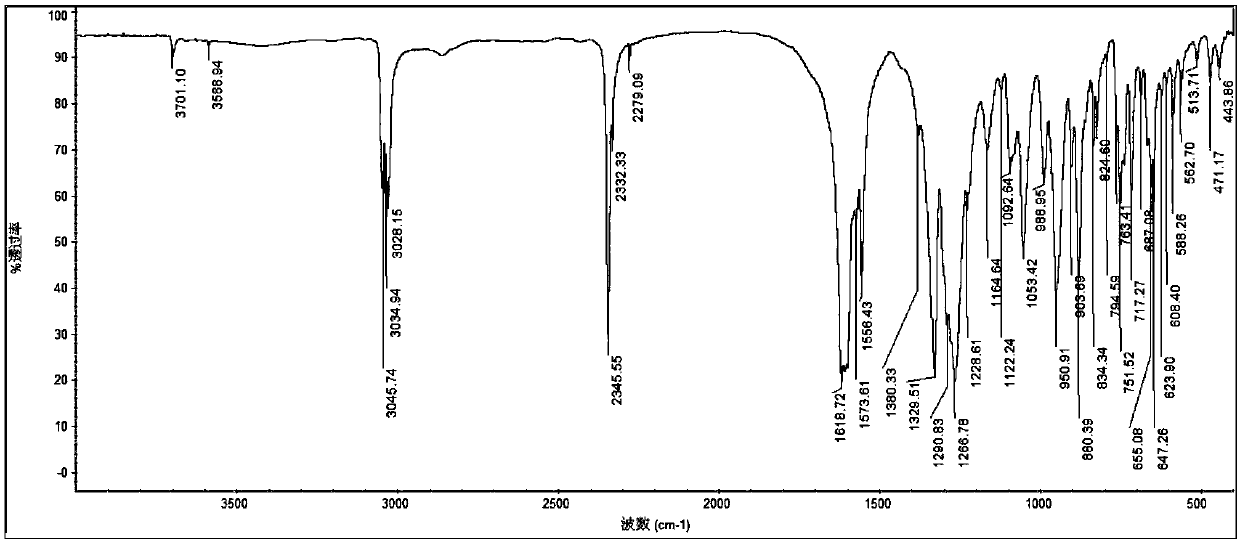

A technology based on isowurtsyl and hexanitrohexanitrogen, which is applied in the refinement of CL-20-based host-guest explosive crystals and the preparation of host-guest explosive crystals, and can solve problems such as multiple cracks, holes, and crystal safety effects , to achieve the effects of increasing the amount of outgassing, improving combustion and detonation performance, and facilitating particle grading and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Measure 50ml of methyl acetate and place it in a 150ml Erlenmeyer flask, weigh 5g of CL-20 raw material, add 0.25g of sodium dodecylbenzene sulfonate to the solution, and magnetically stir until completely dissolved to obtain a CL-20 solution with a concentration of 10%wt.

[0040] (2) Continuously inject CO into a 1000ml cavity made of pressure-resistant glass 2 The gas forms a stable air flow, and the flow rate of the gas is controlled at 1000ml / min through the flow regulating valve, and the temperature of the cavity is kept constant at 40°C by using the insulation jacket.

[0041] (3) Draw 50ml of CL-20 solution with a flat-end needle syringe with a diameter of 0.1mm, and spray the solution into the cavity with small molecule airflow through the syringe needle at a rate of 10ml / min, and at the same time assist the ultrasonic effect outside the cavity , Ultrasonic power is 500W.

[0042] (4) The solvent in the fine liquid droplets is continuously volatilized by ...

Embodiment 2

[0044] (1) Measure 50ml of ethyl acetate and place it in a 150ml Erlenmeyer flask, weigh 22.5g of CL-20 raw material and add it, and add 0.1g of polyvinylpyrrolidone to the solution, magnetically stir until completely dissolved, and obtain CL-20 solution with a concentration of 45%wt.

[0045] (2) Continuously feed N into a 2000ml chamber made of stainless steel 2 O gas forms a stable air flow, and the flow rate of the gas is controlled at 800ml / min through the flow regulating valve, and the temperature of the cavity is kept constant at 80°C by using the insulation jacket.

[0046] (3) Draw 10ml of CL-20 solution with a flat-end needle syringe with a diameter of 0.06mm, and spray the solution into the cavity with small molecule airflow through the syringe needle at a rate of 1ml / min, and at the same time assist the ultrasonic effect outside the cavity , Ultrasonic power is 900W.

[0047] (4) The solvent in the fine liquid droplets is continuously volatilized by continuously ...

Embodiment 3

[0049] (1) Measure 25ml of acetone and 25ml of methanol into a 150ml Erlenmeyer flask, weigh 2.5g of CL-20 raw material, add 0.25g of polyethylene glycol into the solution, and magnetically stir until completely dissolved , to obtain a CL-20 solution with a concentration of 5% wt.

[0050] (2) Continuously inject NO into a 100ml cavity made of Hastelloy 2 The gas forms a stable air flow, and the flow rate of the gas is controlled at 200ml / min through the flow regulating valve, and the temperature of the cavity is kept constant at 20°C by using the insulation jacket.

[0051] (3) Draw 50ml of CL-20 solution with a flat-end needle syringe with a diameter of 0.5mm, and spray the solution into the cavity with small molecule airflow through the syringe needle at a rate of 100ml / min, and at the same time assist the ultrasonic effect outside the cavity , Ultrasonic power is 100W.

[0052] (4) The solvent in the fine liquid droplets is continuously volatilized by continuously feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com