Conductive rail type mobile monitoring robot, monitoring system and method thereof

A mobile monitoring and robot technology, applied in closed-circuit television systems, TV system components, TVs, etc., can solve problems such as dead angles, unstable video images, and cameras that cannot perfectly realize 360° no dead angle monitoring, so as to prevent derailment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

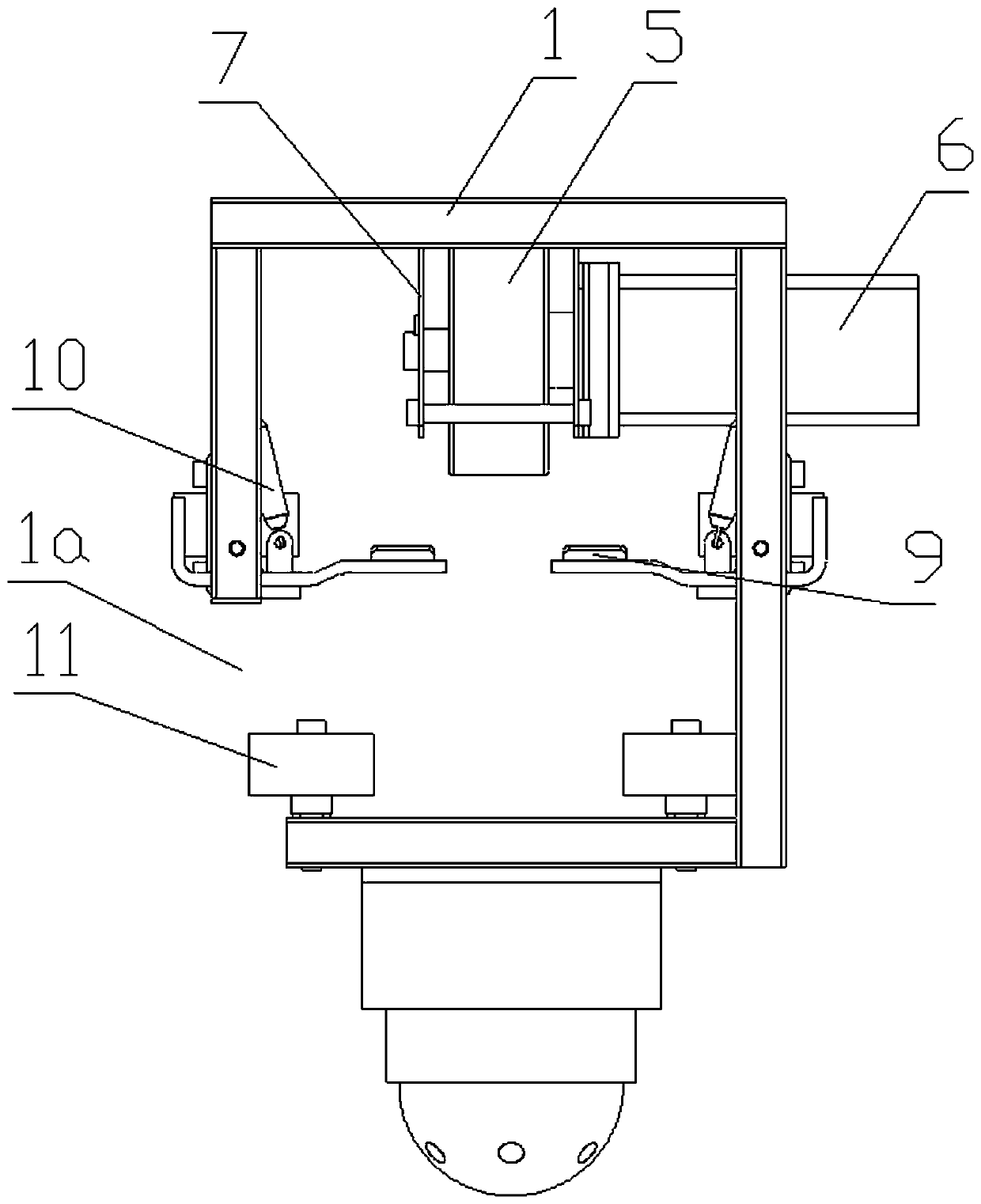

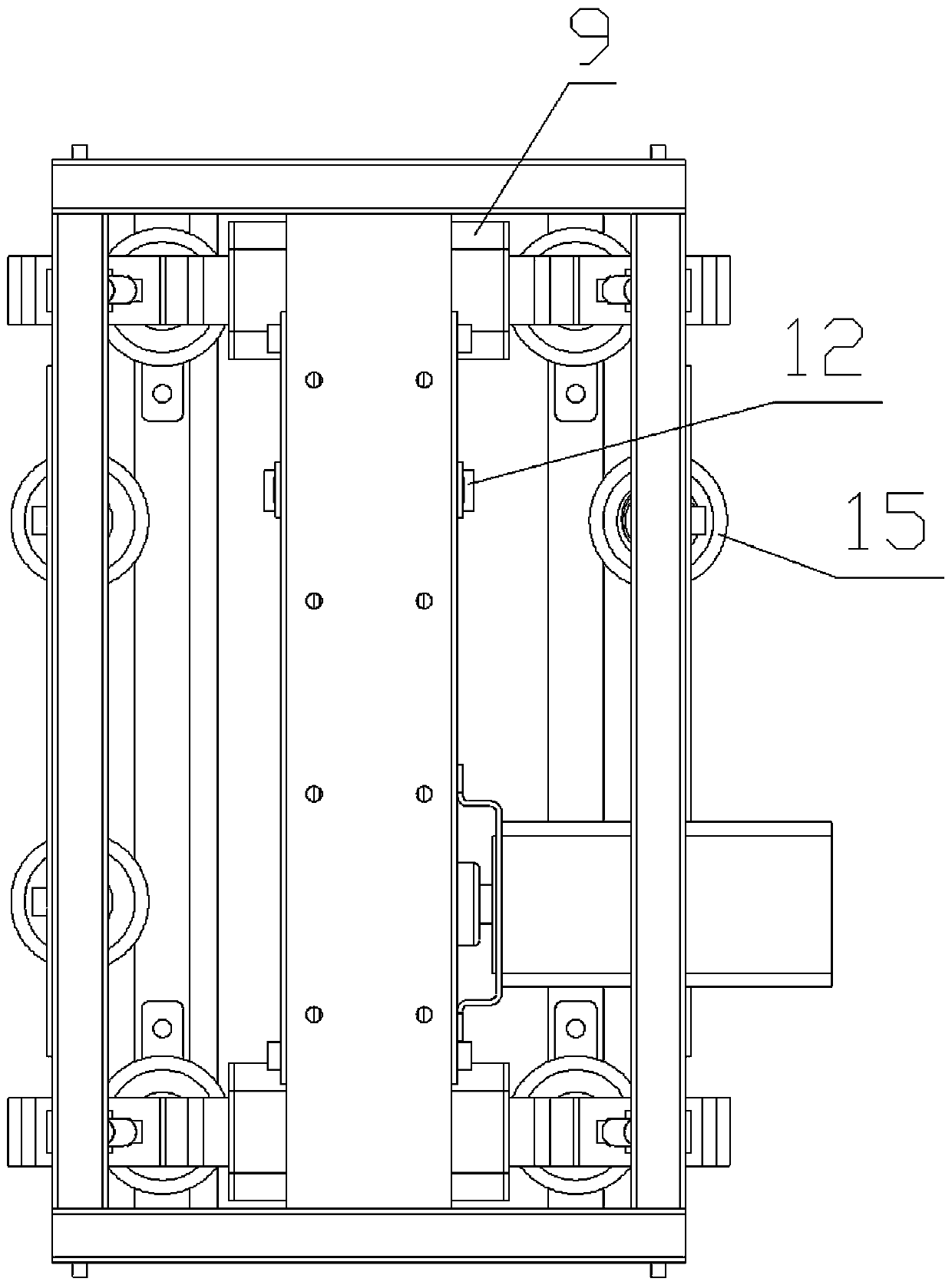

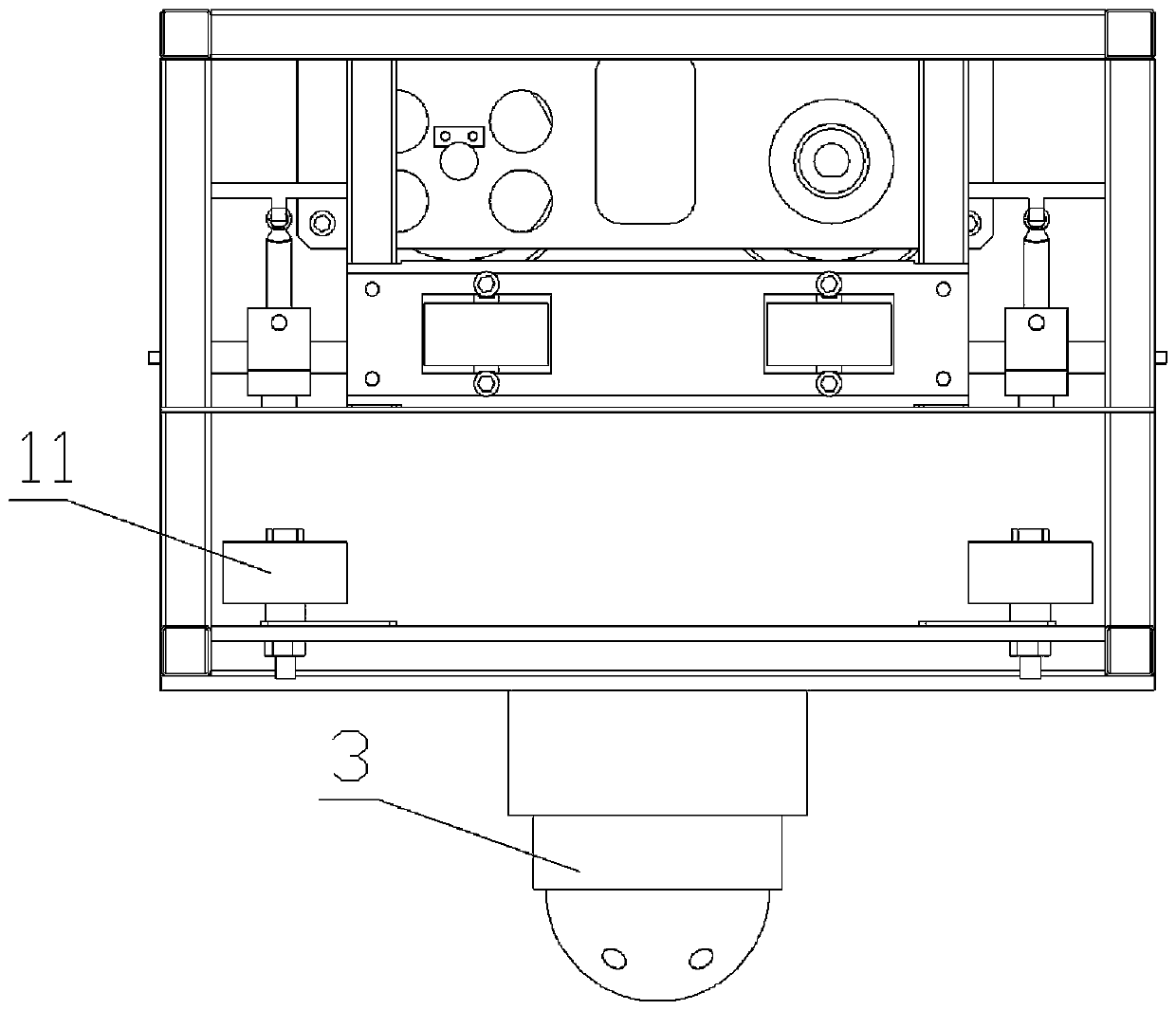

[0031] see Figure 1 to Figure 6 , a conductive rail-type mobile monitoring robot, including a car body 1, a camera device 3 is fixed on the car body 1, the car body 1 is installed on a walking track 4, and the upper, lower, left, and right positions are limited, and the walking track 4 Through the car body 1, the car body 1 is rotatably supported with a traveling wheel 5, the traveling wheel 5 is in contact with the upper end surface of the traveling track 4, and the traveling wheel 5 is fixedly connected with the driving motor 6, and the driving motor 6 is used to drive the running wheel 5 to rotate, so that the car body 1 can walk and move along the running track 4, the drive motor 6 and the camera device 3 are electrically connected to the control system 2, and the running track 4 is fixed with a conductive rail 8, so that A carbon brush 9 is fixed on the car body 1, and the carbon brush 9 is in sliding contact with the conductive rail 8 on the running track 4 to form an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com