Novel tobacco-leaf harvesting device

A new type of tobacco leaf technology, applied in the field of new tobacco leaf harvesting devices, can solve problems such as difficulty in adjustment, affecting harvesting work efficiency, high labor resources, etc., and achieve the effects of facilitating disassembly and installation, protecting tobacco leaf plants, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

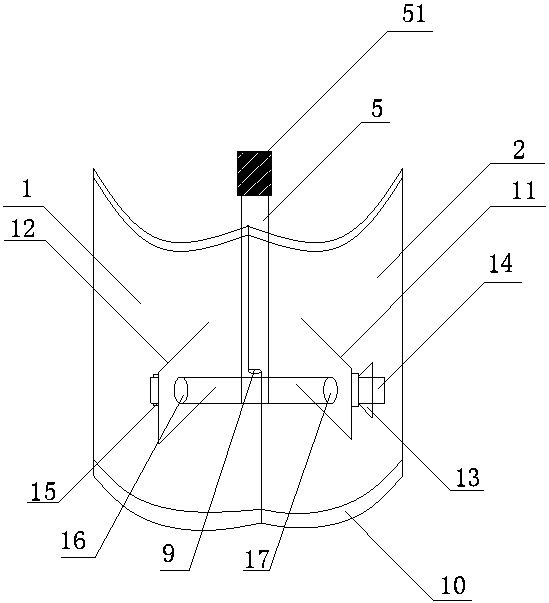

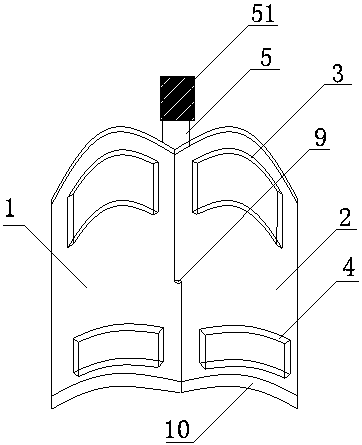

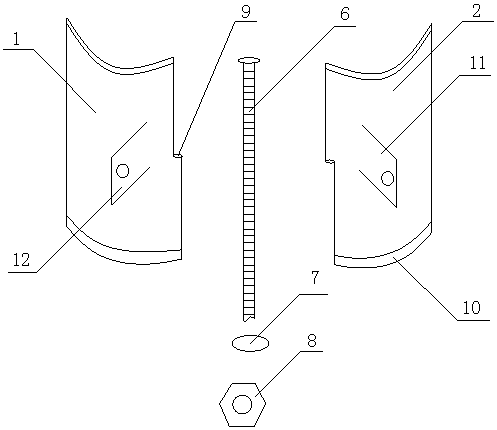

[0028] like figure 1 , 2 , 3, and 4, a novel tobacco harvesting device includes a harvesting body, the harvesting body is formed by a left side arc blade 2 and a right side arc blade 1 movably connected by a connecting shaft, and the right side arc blade 2 The bottom is the blade 10, the left side arc blade 2 is provided with a left adjustment plate 12, the left adjustment plate 12 is provided with a left connection hole 16, corresponding to the left side arc blade 2, and the right side arc blade 1 is provided with Right adjusting plate 11, right adjusting plate 11 is provided with right connecting hole 17, left connecting hole 16 and right connecting hole 17 are connected by connecting rod 14, and one end of connecting rod 14 is provided with fixing part 15, and the other end is provided with regulating head 13. The fixing part 15 is provided with a through hole a corresponding to the left connecting hole 16, the fixing part 15 is arranged on the outside of the left adjustin...

Embodiment 2

[0032] like figure 1 , 2 , 3, and 4, a novel tobacco harvesting device includes a harvesting body, the harvesting body is formed by a left side arc blade 2 and a right side arc blade 1 movably connected by a connecting shaft, and the right side arc blade 2 The bottom is the blade 10, the left side arc blade 2 is provided with a left adjustment plate 12, the left adjustment plate 12 is provided with a left connection hole 16, corresponding to the left side arc blade 2, and the right side arc blade 1 is provided with Right adjusting plate 11, right adjusting plate 11 is provided with right connecting hole 17, left connecting hole 16 and right connecting hole 17 are connected by connecting rod 14, and one end of connecting rod 14 is provided with fixing part 15, and the other end is provided with regulating head 13. The fixing part 15 is provided with a through hole a corresponding to the left connecting hole 16, the fixing part 15 is arranged on the outside of the left adjustin...

Embodiment 3

[0039] like figure 1 , 2 , 3, and 4, a novel tobacco harvesting device includes a harvesting body, the harvesting body is formed by a left side arc blade 2 and a right side arc blade 1 movably connected by a connecting shaft, and the right side arc blade 2 The bottom is the blade 10, the left side arc blade 2 is provided with a left adjustment plate 12, the left adjustment plate 12 is provided with a left connection hole 16, corresponding to the left side arc blade 2, and the right side arc blade 1 is provided with Right adjusting plate 11, right adjusting plate 11 is provided with right connecting hole 17, left connecting hole 16 and right connecting hole 17 are connected by connecting rod 14, and one end of connecting rod 14 is provided with fixing part 15, and the other end is provided with regulating head 13. The fixing part 15 is provided with a through hole a corresponding to the left connecting hole 16, the fixing part 15 is arranged on the outside of the left adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com