Modularized greenhouse water culture structure

A greenhouse and modular technology, applied in the field of modular greenhouse hydroponic structure, can solve the problems of inability to use high-efficiency large-scale production, difficult control of pipeline liquid temperature, waste of resources, etc., to achieve industrialized agricultural production and benefit daily life The effect of maintenance management, convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

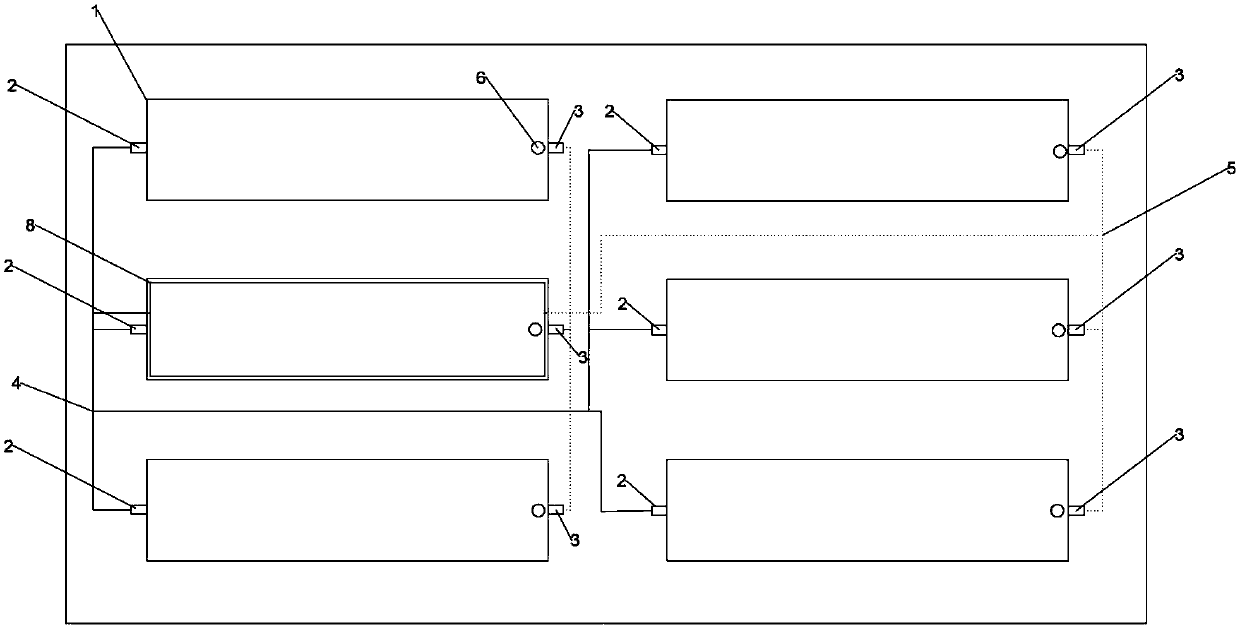

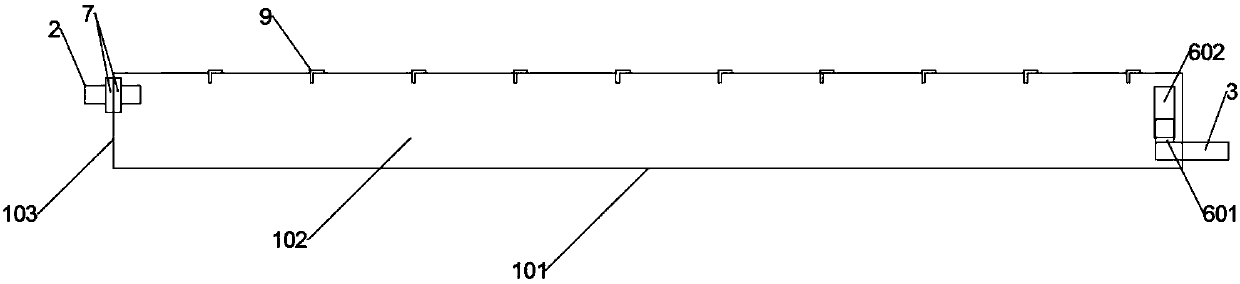

[0027] Such as figure 1 with 2 As shown, a modular greenhouse hydroponic structure includes a plurality of hydroponic pools 1 arranged in the greenhouse, wherein a nutrient solution pool 8 is dug at the lower end of one of the hydroponic pools 1, and the nutrient solution pool 8 passes through A suction pump and a plurality of infusion tubes 4 are respectively communicated with each of the hydroponic pools 1, and an overflow device 6 is arranged on the hydroponic pool 1, and each of the overflow devices 6 is connected to the nutrient via the liquid return pipe 5. The biochemical filter in the liquid pool 8 is filtered and returned to the nutrient solution pool 8; each of the hydroponic pools 1 includes a bottom plate 101, two long side plates 102 and two short side plates 103 arranged around the bottom plate 101 , a plurality of support rods 9 are arranged between the two long side plates 101 extending along the length direction.

[0028] The bottom plate 101 is sealed and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com