Novel elevator guide rail

An elevator guide rail and a new type of technology, applied in the field of guide rails, can solve the problems of poor pressing plate pressing effect, poor performance and high price, and achieve the effects of reducing cross-sectional area, improving mechanical performance and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

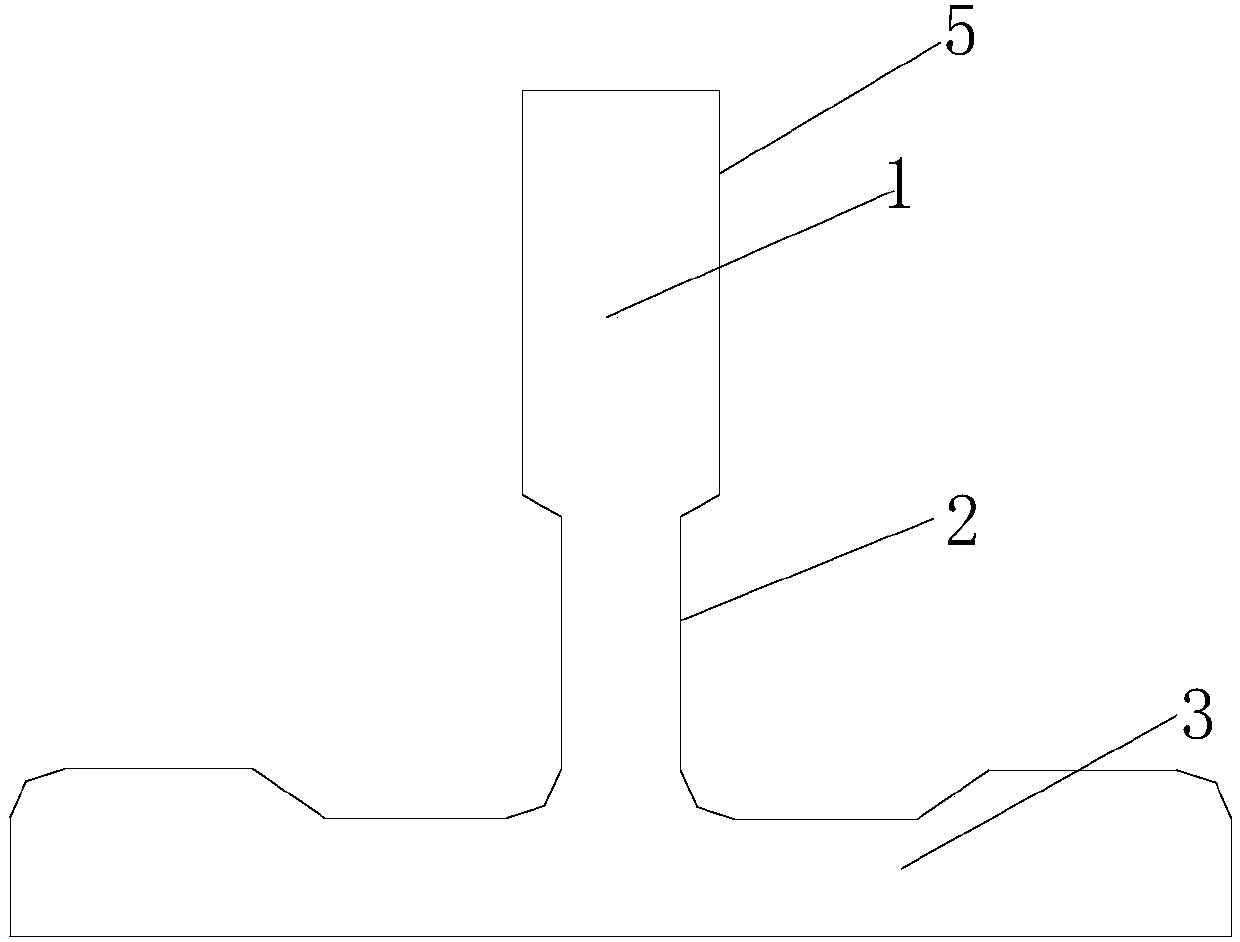

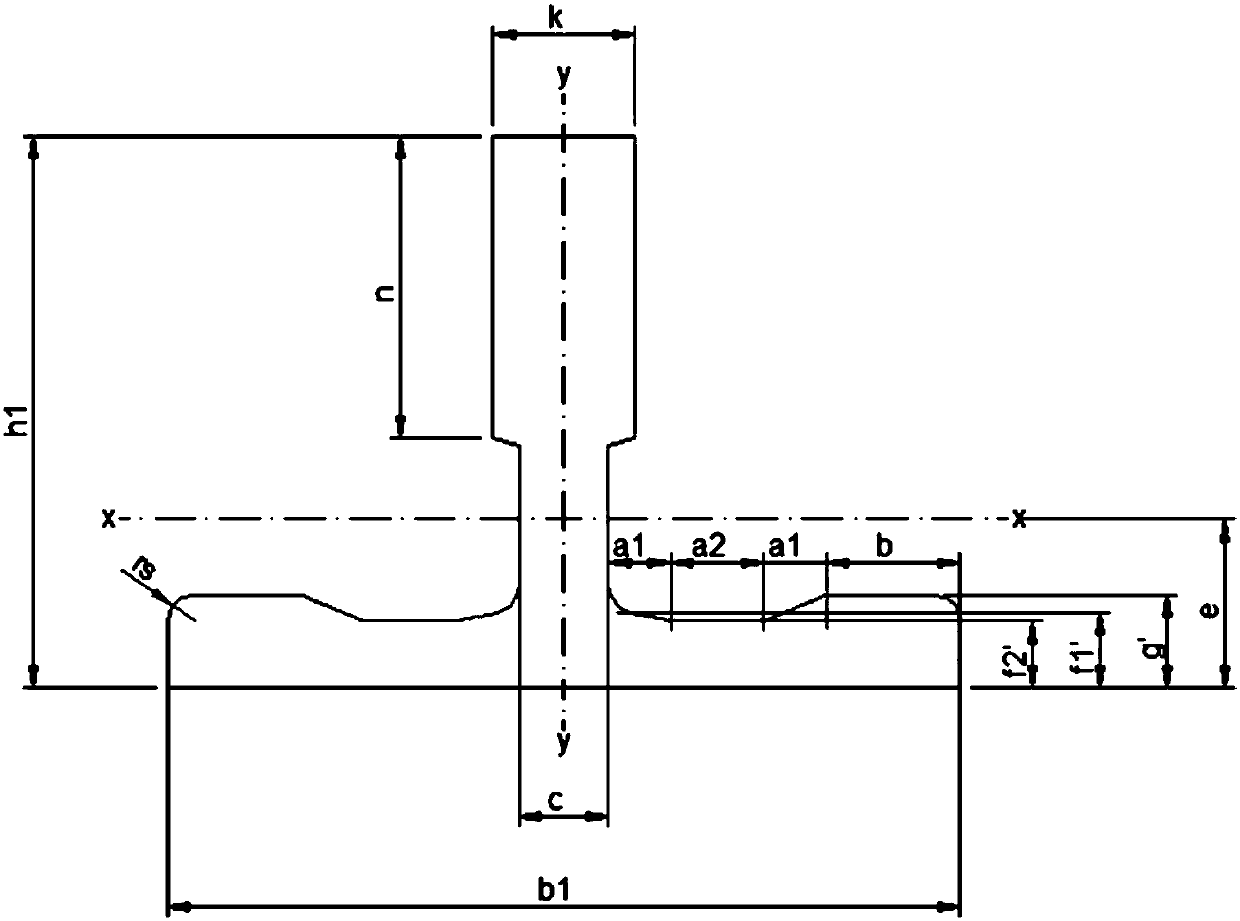

[0014] Embodiment 1: refer to image 3 , a cost-saving solution to improve mechanical performance

[0015] g'=f-s1

[0016] f2'=g-s2

[0017]

[0018]

[0019]

[0020]

[0021] When the cross-sectional areas S1, S2, S3, S4, and S5 are reduced by no less than 2%, the moment of inertia in the Y-Y direction can be increased by a minimum of 5%. The moment of inertia is the moment of inertia in the X-X direction of the standard guide rail that should not be less than 1%. At the same time, this design has a better pressing effect on the supporting platen of the guide rail in the Y-Y direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com