An automatic sewing needle threading system for industrial use

A kind of needle threading and industrial technology, which is applied to sewing equipment, sewing machine components, and thread cutting mechanisms in sewing machines, etc., can solve the problems of low needle threading efficiency, difficulty in fast and efficient needle threading, manual needle placement, etc., to improve needle retrieval. Efficiency, stable needle push process, and the effect of liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

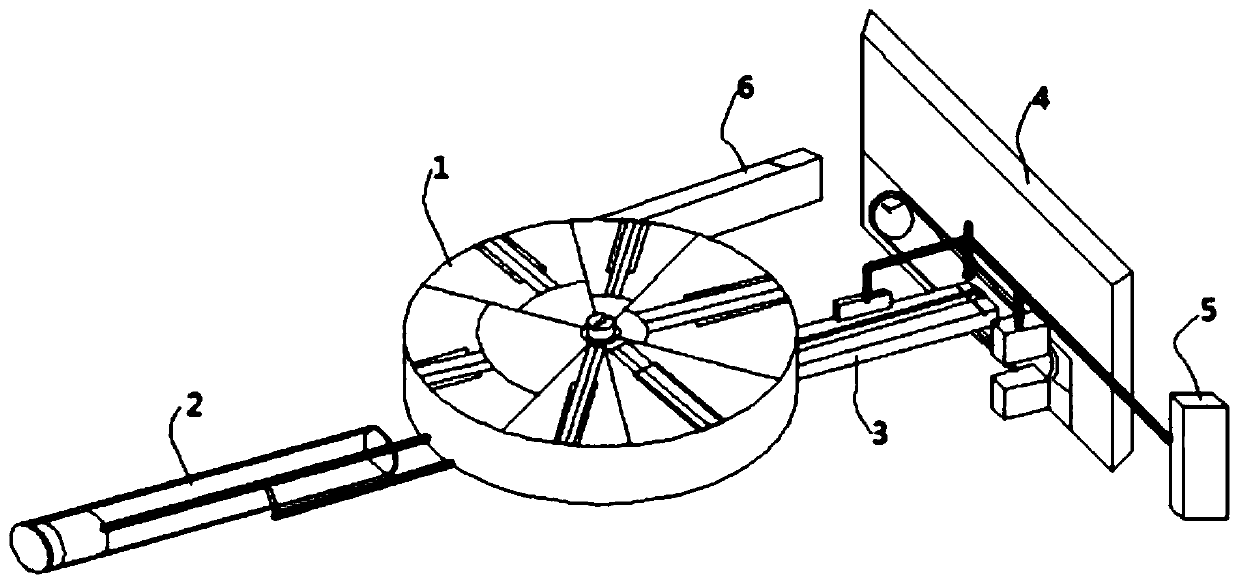

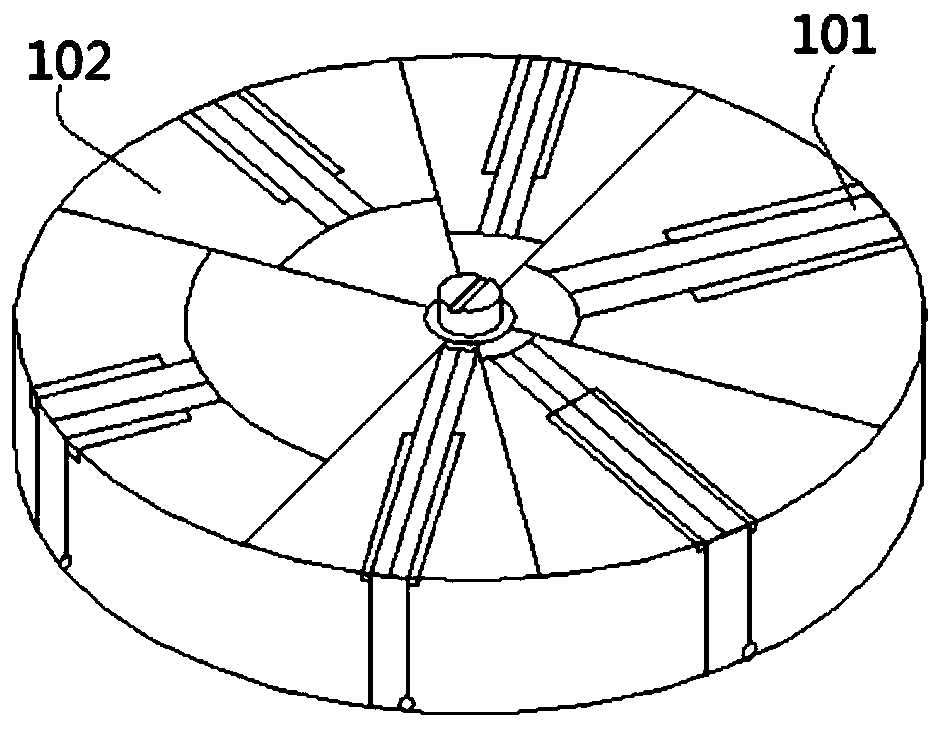

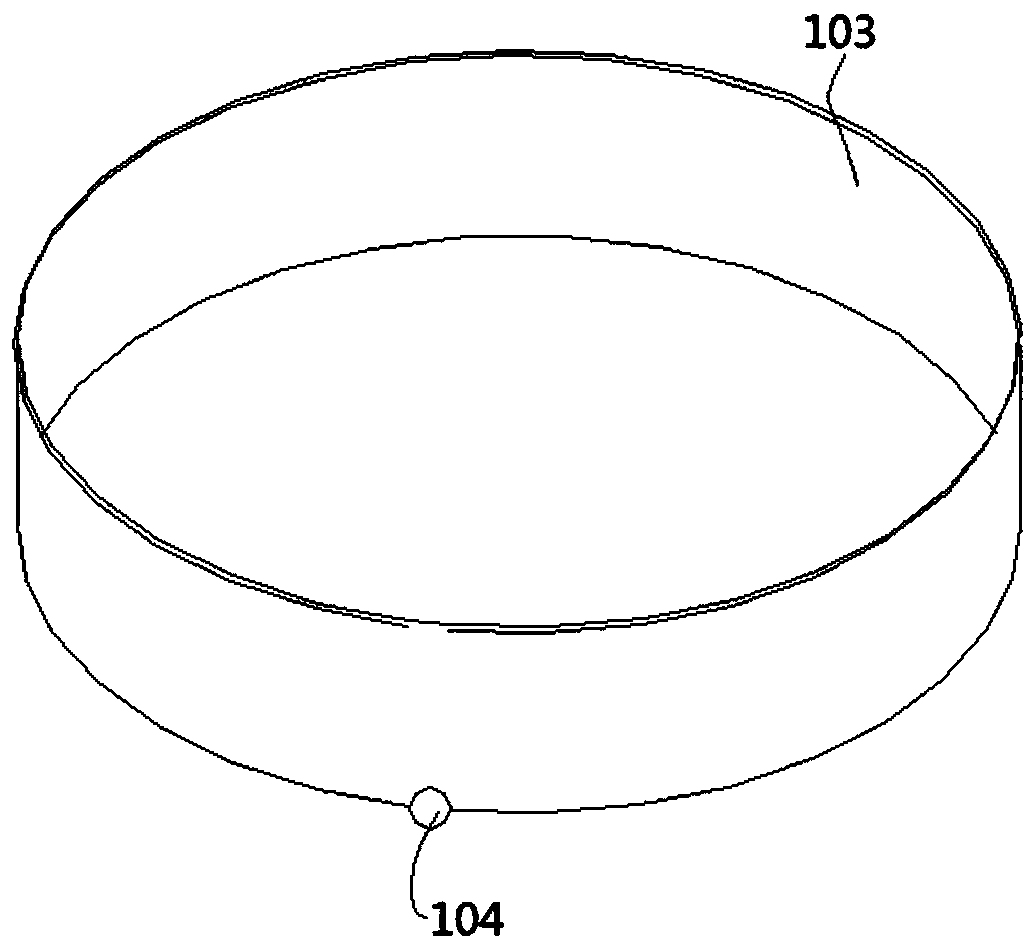

[0048] combine figure 1 , an automatic sewing and needle threading system for industrial use in this embodiment, including a needle storage device 1, a needle pushing device 2, a needle transport device 3, a thread pulling device 4, a needle threading device 5, a needle output device 6, a thread trimmer device and control system; one side of the needle storage device 1 is provided with a needle pushing device 2, and the other side is provided with a needle movement device 3; the end of the needle movement device 3 far away from the needle storage device 1 is provided with a wire pulling device 4, A needle threading device 5 is arranged above one end of the needle moving device 3 close to the wire pulling device 4; the needle output device 6 is arranged on one side of the needle moving device 3; the thread cutting device is arranged on one side of the pulling wire device 4; The control system controls the action of each device of the automatic threading system.

[0049] combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com