Workpiece contour scanning system and method thereof

A workpiece contour and scanning system technology, applied in the field of workpiece contour scanning system, can solve the problems of wasting manpower and material resources, insecurity, etc., and achieve the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

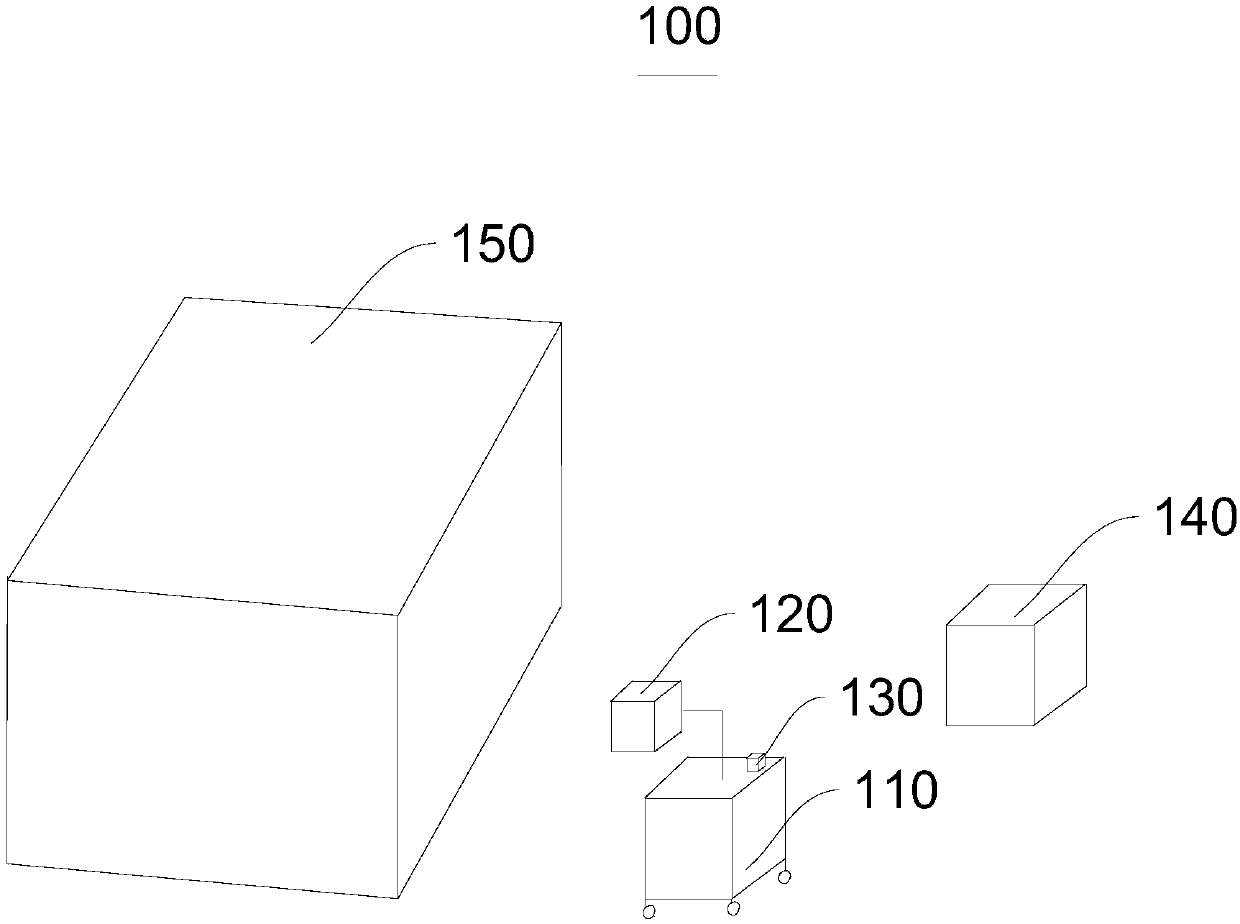

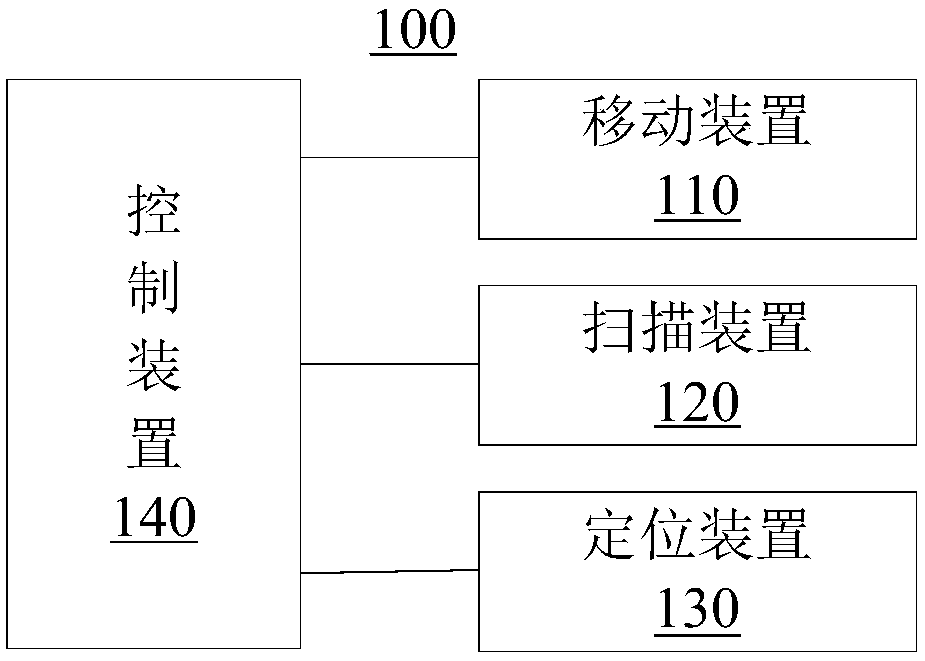

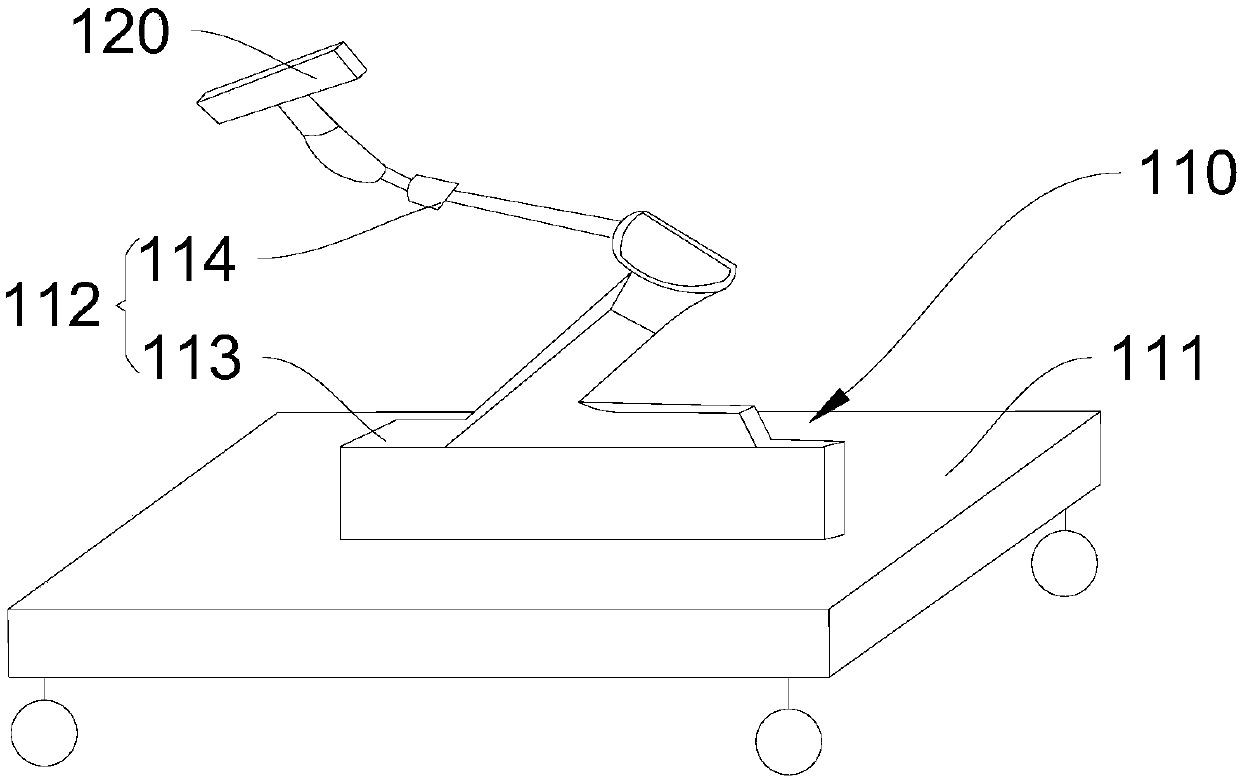

[0026] The first embodiment of the present invention provides a workpiece contour scanning system 100, please refer to figure 1 , the workpiece contour scanning system 100 includes a moving device 110 , a scanning device 120 , a positioning device 130 and a control device 140 . Wherein, the scanning device 120 and the positioning device 130 are both disposed on the mobile device 110 . See figure 2 , the control device 140 is respectively connected to the mobile device 110 , the scanning device 120 and the positioning device 130 .

[0027] In the embodiment of the present invention, the positioning device 130 is used to obtain the location information of the mobile device 110 and transmit it to the control device 140; the control device 140 is used to control the mobile device 110 to drive the scanning device 120 to move based on the location information and the preset movement path, and Control the mobile device 110 to adjust the three-dimensional posture of the scanning de...

no. 2 example

[0058] The second embodiment of the present invention provides a workpiece contour scanning method, which is applied to the workpiece contour scanning system provided by the first embodiment of the present invention. See Figure 4 , the workpiece contour scanning method includes:

[0059] Step S110: the positioning device acquires location information of the mobile device, and transmits the location information to the control device.

[0060] Step S120: The control device controls the moving device to drive the scanning device to move based on the position information and the preset moving path, and controls the moving device to adjust the three-dimensional posture of the scanning device relative to the workpiece to be measured.

[0061] Step S130: Driven by the moving device, the scanning device acquires contour data of the entire outer surface area of the workpiece to be measured, and transmits the contour data to the control device.

[0062] Step S140: the control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com