Measuring device and method for stratified steam distribution valve flow rate

A measuring device and measuring method technology, which are applied in the direction of volume/mass flow generated by mechanical effects and the detection of fluid flow by measuring pressure difference, which can solve the problem of aggravating the steam overload of single-layer inrush, reducing the longitudinal sweep efficiency of steam flooding, affecting the steam flow. It can solve the problems such as the effect of flooding and mining, and achieve the effect of novel structure design, reduced impact and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

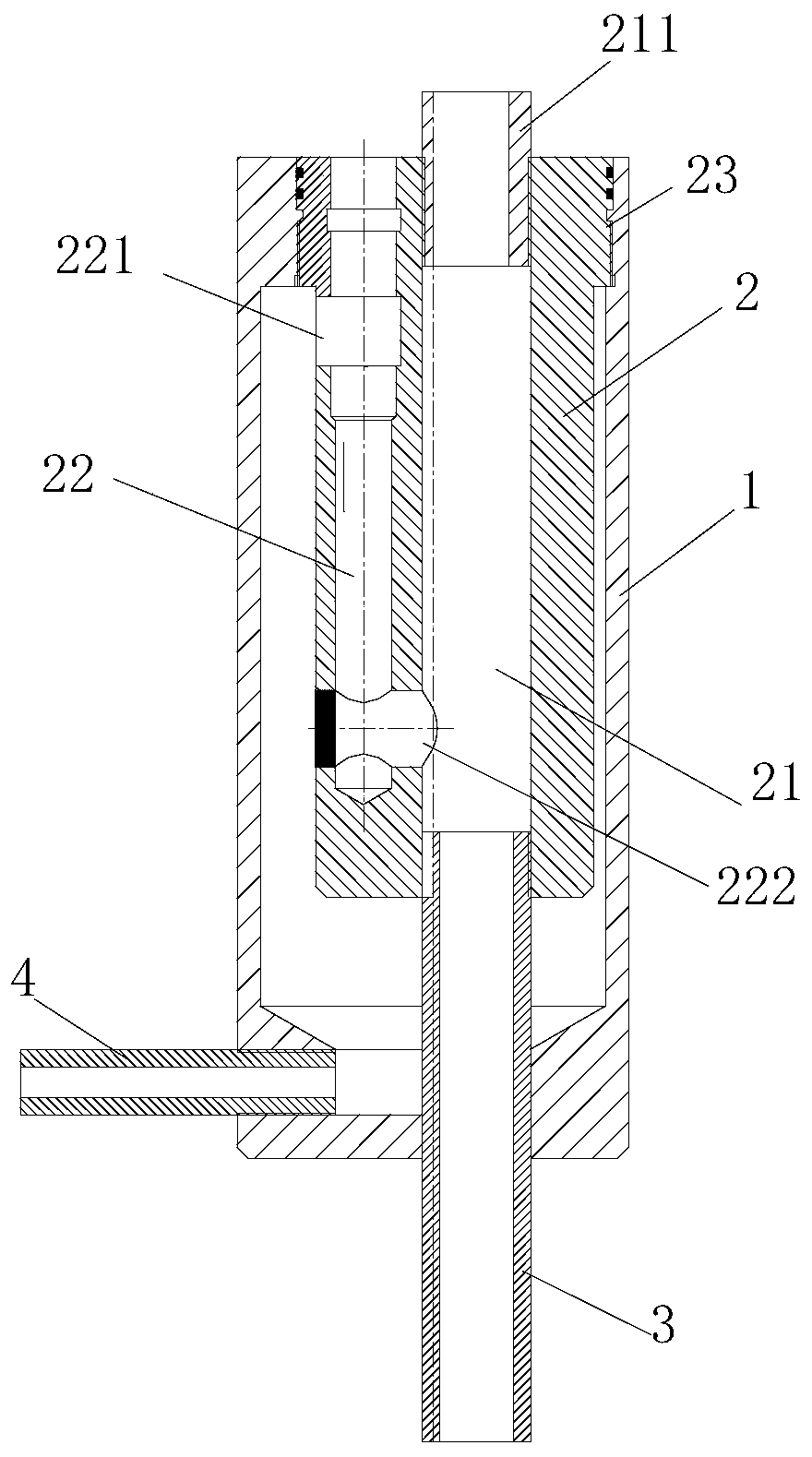

[0037] The present invention proposes a measuring device for the flow rate of a layered steam distribution valve, comprising: an outer sleeve; a valve seat located in the outer sleeve, and its upper end is sealedly connected with the mouth of the outer sleeve; The seat is provided with a through flow channel in the axial direction, and an axial slot for inserting the layered steam distribution valve is formed adjacent to the side of the flow channel, and the upper port of the flow channel of the valve seat is plugged There is an upper joint, the upper end of the axial slot communicates with the inner cavity of the outer sleeve, and the lower end communicates with the flow channel; the main pipe is axially installed at the bottom of the outer sleeve , the upper end of which is plugged into the lower port of the flow channel; the bypass branch pipe, close to the lower end of the outer sleeve, is inserted into the side wall of the outer sleeve in the radial direction, and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com