Anti-fragmentation system and method for slice loading of slice scanner

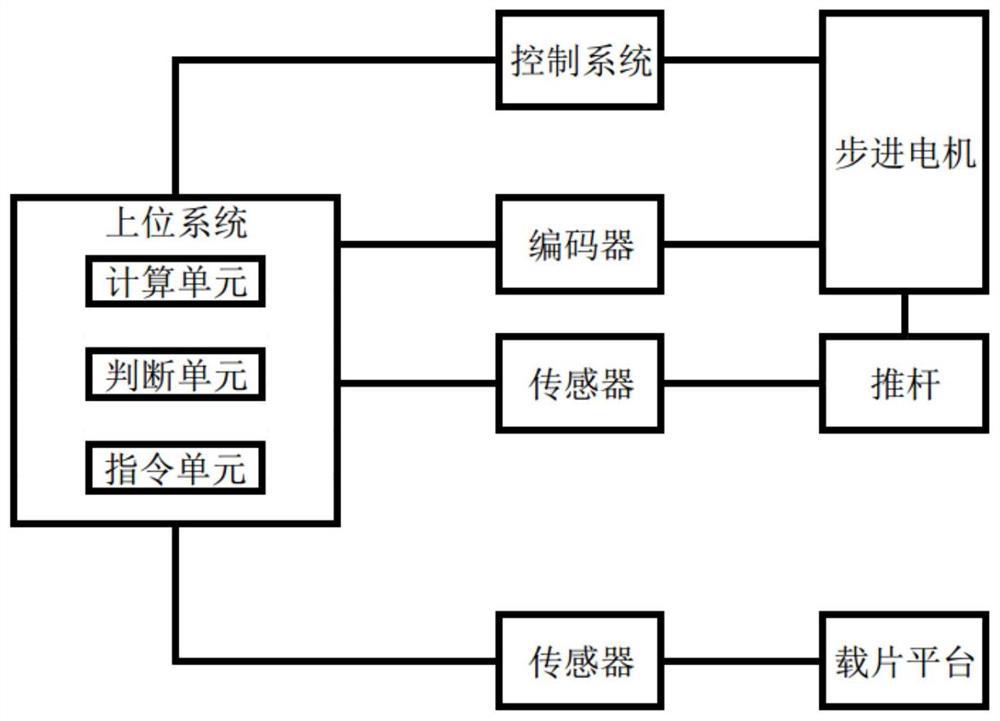

A slicing scanner and slicing technology, which is applied to the program control and electrical program control of the sequence/logic controller, and can solve problems such as unreachable, pulse number n deviation, slice fragments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

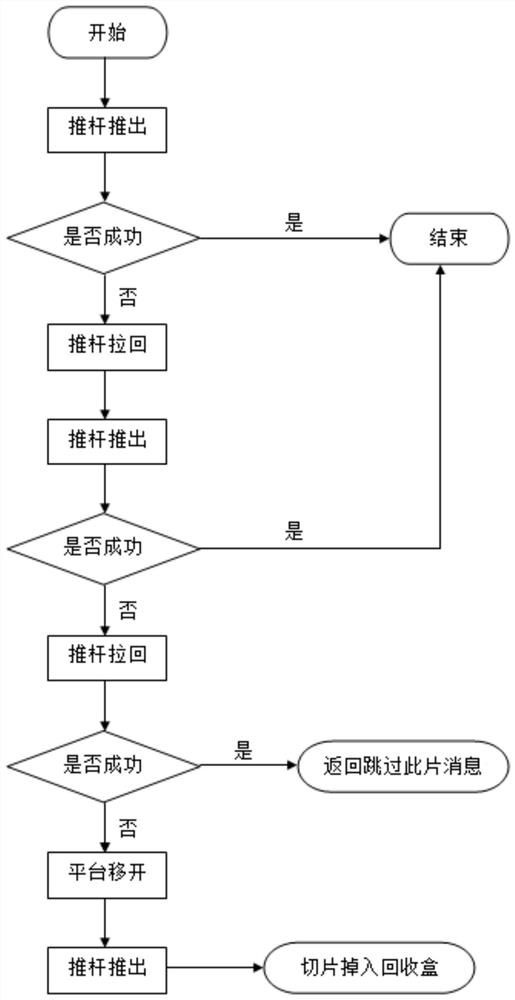

[0108] A specific embodiment of the present invention, its application is as follows:

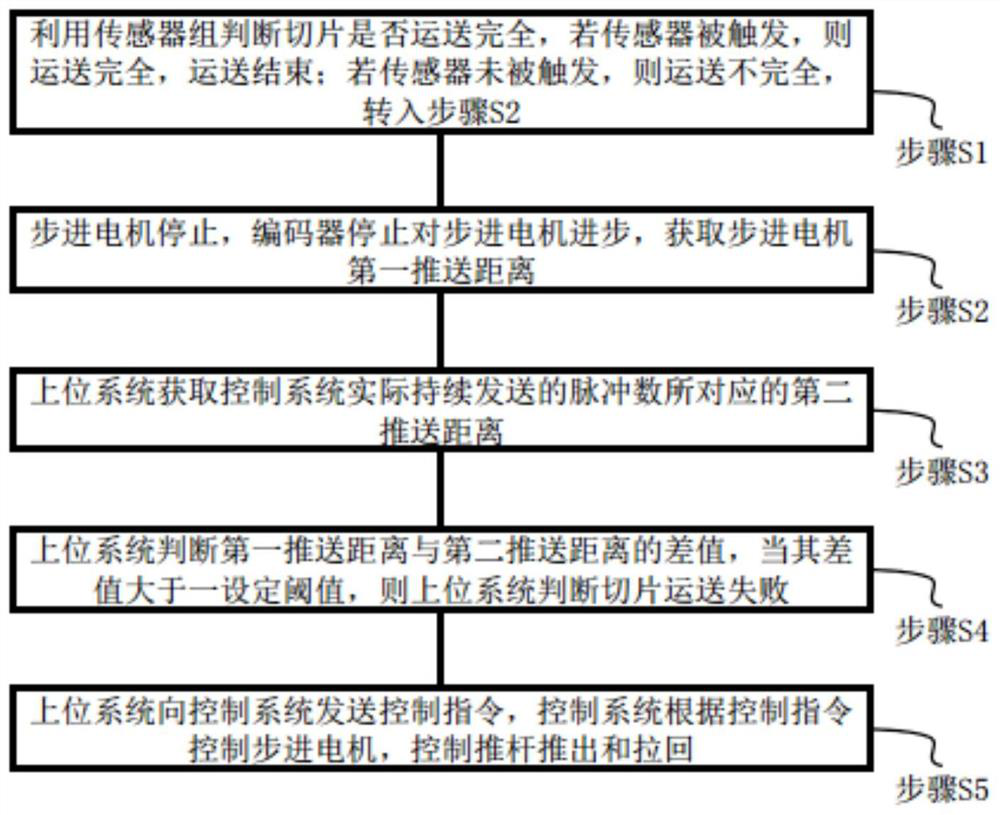

[0109] Step S1, use the sensor to judge whether the slice is transported completely, if the sensor is triggered, the transport is complete, and the transport is completed; if the sensor is not triggered, the transport is incomplete, and then go to step S2;

[0110] Step S2. At this time, the stepping motor stops moving, and the encoder also stops counting the steps of the stepping motor. The encoder sends the data recorded by it to the upper system, including the number of pulses N2, the distance X2 of the motor’s rotation, and the stepping motor’s first step. A pushing distance S2, and S2=N2*X2;

[0111] Step S3, the upper system obtains the data actually sent by the control system, including the number of pulses N1, the distance X1 of the motor running one circle, and the corresponding second push distance S1, and S1=N1*X1;

[0112] The upper system can obtain the data that the control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com