A system and method for automatic lamination production of transformer silicon steel sheet

A production system, silicon steel sheet technology, applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low productivity and uneven quality of manual stacking, and achieve compact structure, The effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

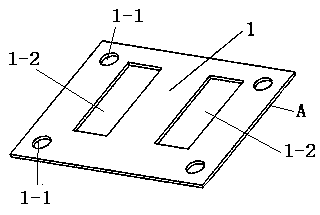

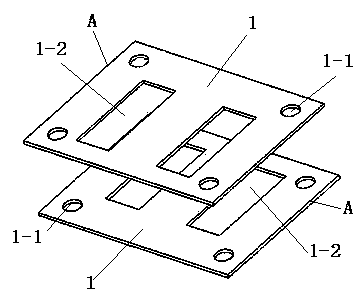

[0032] see figure 1 As shown, the silicon steel sheet 1 is a rectangular parallelepiped structure, each of the four sides has a through hole 1-1 of the same size, and the middle part has two rectangular through grooves 1-2 of the same size, and the short length of the rectangular through groove 1-2 The long side of edge corresponding silicon steel sheet 1, promptly the short side of rectangular through groove 1-2 is parallel with the long side of silicon steel sheet 1, and the long side of rectangular through groove 1-2 is parallel with the short side A of silicon steel sheet 1, and The spacing between the two short sides of the two rectangular through grooves 1-2 and the corresponding two long sides of the silicon steel sheet 1 is different, that is, the two rectangular through grooves 1-2 are closer to one long side of the silicon steel sheet 1 as a whole, and the spacing is relatively small. Small, the other long side is farther away, and the spacing is large.

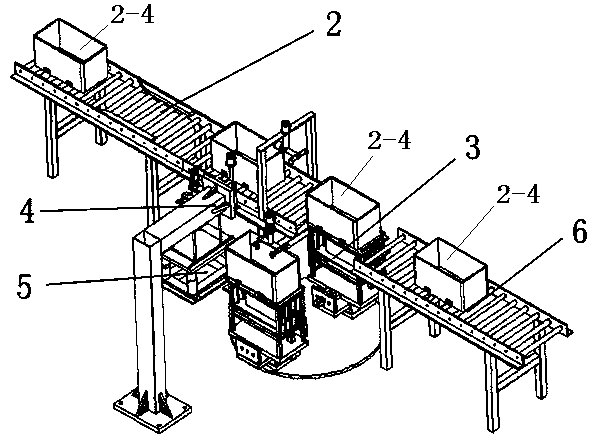

[0033] see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com