Nonaqueous electrolyte battery, battery pack and vehicle

A non-aqueous electrolyte and battery pack technology, which is applied in the manufacture of non-aqueous electrolyte batteries, non-aqueous electrolytes, and electrolyte batteries, to achieve the effect of improving high-temperature storage performance and high-current performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

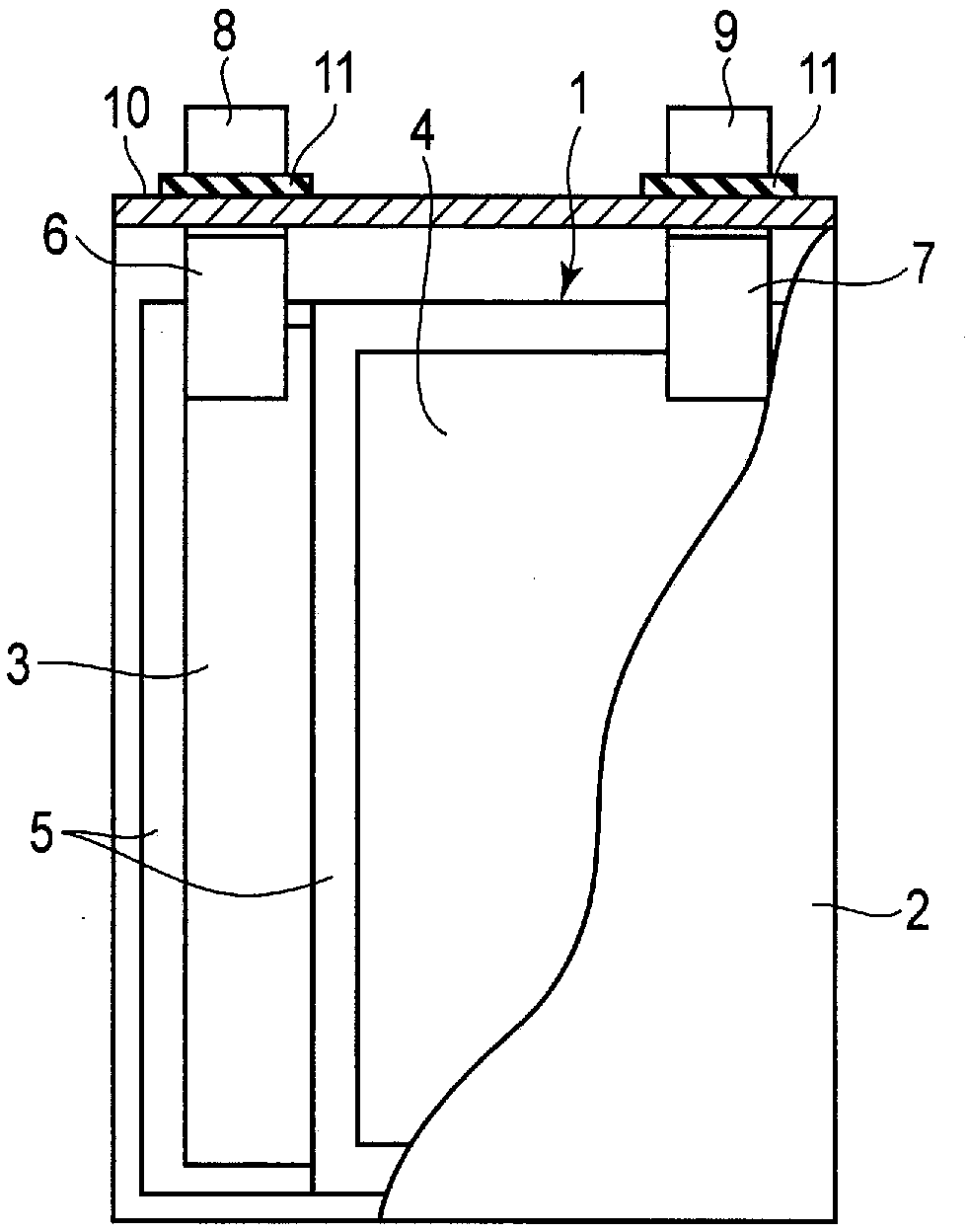

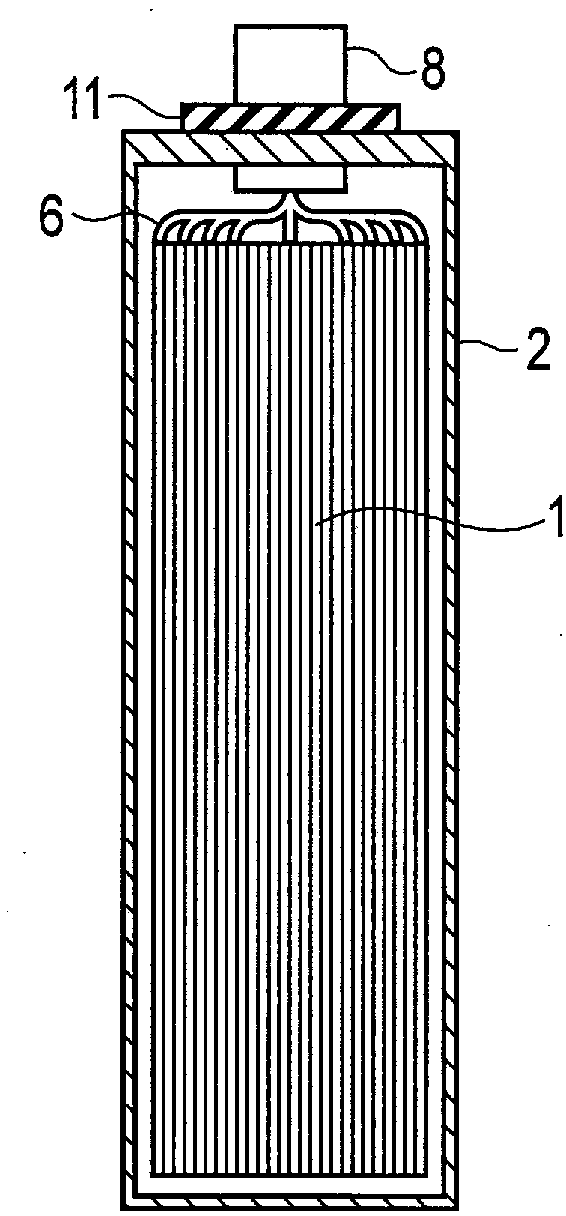

[0026] According to the first embodiment, there is provided a non-aqueous electrolyte battery including a positive electrode, a negative electrode, and a non-aqueous electrolyte. The positive electrode includes positive electrode active material secondary particles and a coating layer. The average secondary particle size of the positive electrode active material secondary particles is 3 μm or more and 25 μm or less. The coating layer coats at least a part of the surface of the positive electrode active material secondary particles. In addition, the coating layer contains lithium titanium oxide and has a thickness of 3 nm or more and 30 nm or less. The shortest distance between the positive electrode and the negative electrode is 12 μm or less.

[0027] Here, the shortest distance between the positive electrode and the negative electrode refers to the smallest distance among the distances between the positive electrode active material-containing layer and the negative electrode ...

no. 2 Embodiment approach

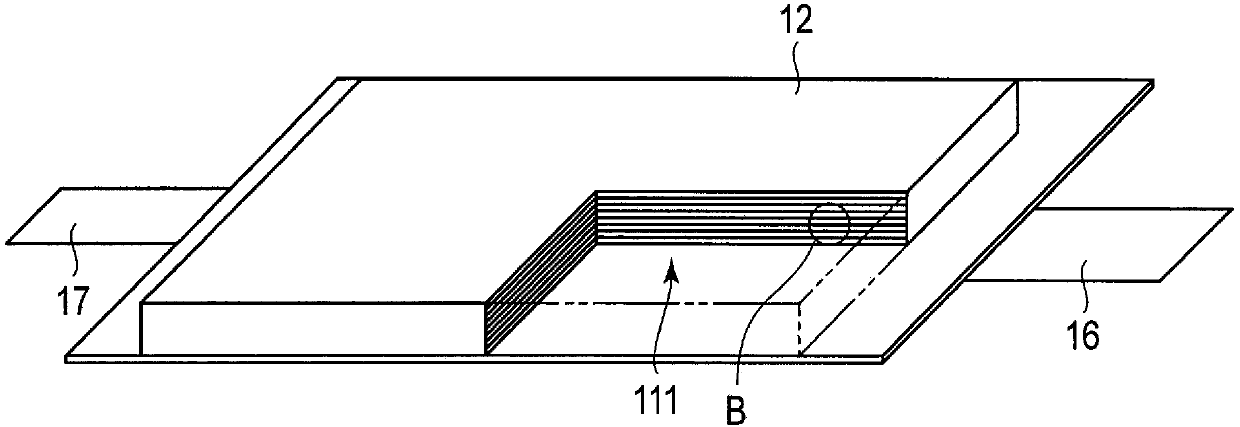

[0125] According to a second embodiment, an assembled battery and battery pack including a non-aqueous electrolyte battery are provided. For the non-aqueous electrolyte battery, for example, the non-aqueous electrolyte battery described in the first embodiment is used.

[0126] As a form in which a plurality of non-aqueous electrolyte batteries are electrically connected in series, a metal bus bar (such as aluminum, nickel, copper) can be used to connect the positive terminal and the negative terminal to connect the multiple non-aqueous electrolyte batteries. Connect in series. In addition, the electrode groups are only electrically connected in series in one battery outer casing, and partition walls are electrochemically provided to form an insulating internal structure, so that a plurality of electrode groups can be accommodated. Furthermore, as a form in which a plurality of non-aqueous electrolyte batteries are electrically connected in series, it is preferable to implement ...

Embodiment 1

[0158] For the positive electrode active material, LiMn with an average secondary particle size of 7μm and a spinel structure is used 2 O 4 Secondary particles. Composition LiMn 2 O 4 The average primary particle size of the primary particles of the secondary particles is 0.9 μm. In the LiMn 2 O 4 The surface of the particles is covered with Li by the following method 4 Ti 5 O 12 .

[0159] A solution obtained by mixing titanium tetraisopropoxide (TTIP) and lithium alkoxide in an ethanol solvent at a ratio of 4:5 was prepared. The solution was sprayed using a rotating fluidized bed coating device and coated on LiMn so that the coating amount became 4% by weight 2 O 4 Particles. After drying at 80°C, heat treatment is carried out at 500°C in the atmosphere for 1 hour, whereby Li with a thickness of 10nm can be 4 Ti 5 O 12 Layer coated on LiMn 2 O 4 Particles. LiMn in production 2 O 4 In the particles, 5% by weight of graphite powder is blended as a conductive agent to the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap