Filtering apparatus for scraps produced in cleaning of cylinder cover of engine

A technology of engine cylinder head and filter device, which is applied in the field of mechanical processing, can solve the problem of large waste debris left in the cleaning tank, and achieve the effect of good promotion and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

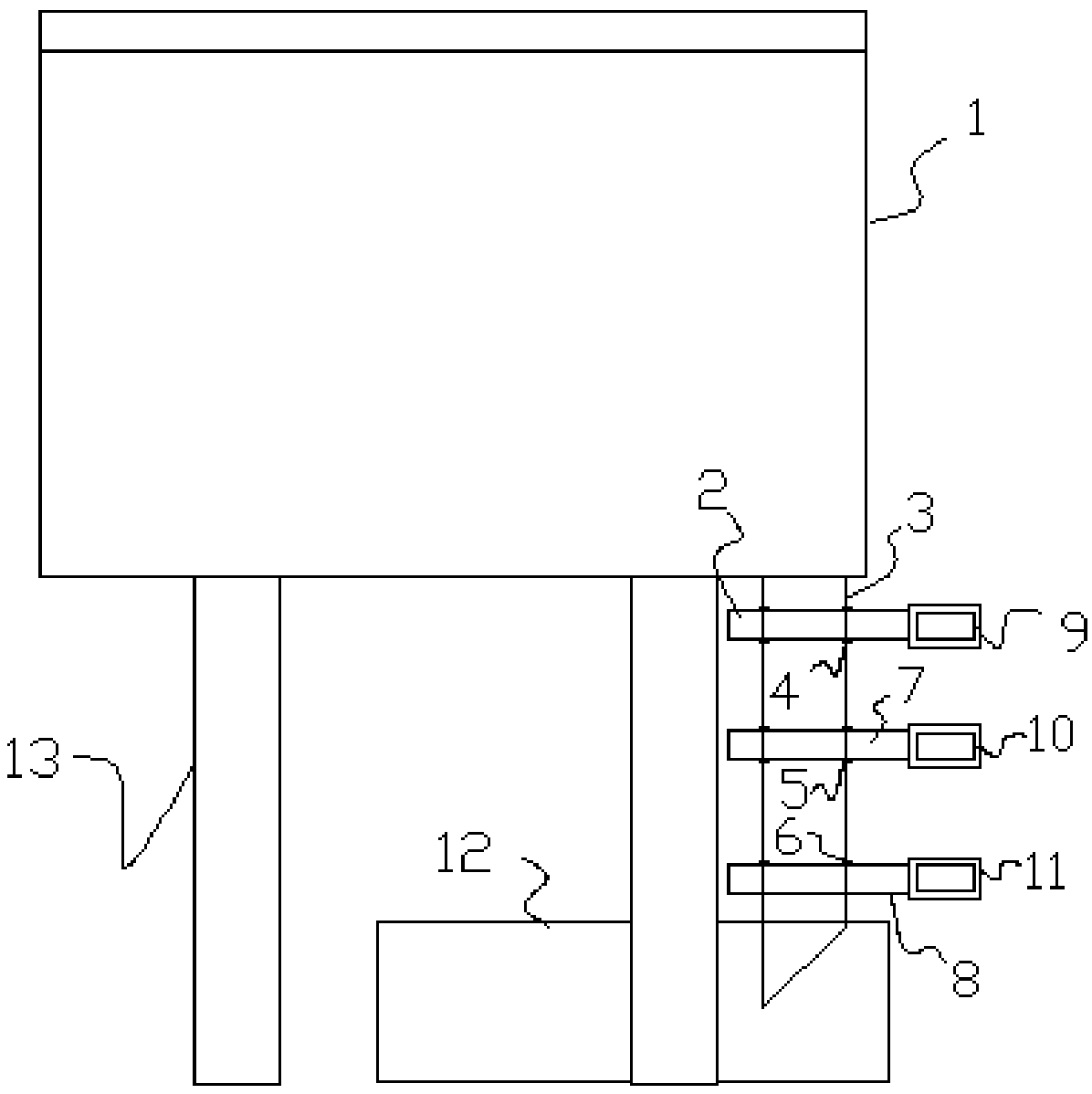

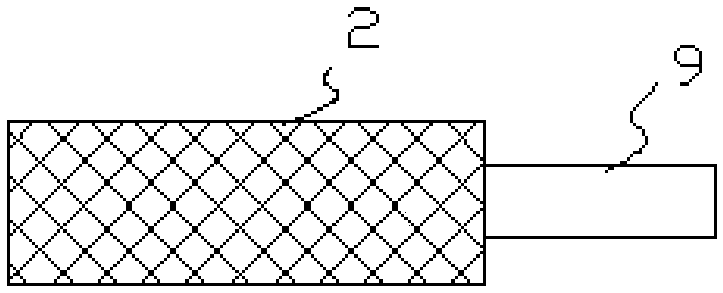

[0019] Such as figure 1 , figure 2 As shown, this kind of waste filter device for engine cylinder head cleaning has a structure including a cleaning tank 1 and a leg 13, and a drain pipe 3 is vertically provided on the bottom side of the cleaning tank 1, and the drain pipe 3 The pipe 3 is provided with a first jack 4, a second jack 5 and a third jack 6 sequentially from top to bottom, the first jack 4 is inserted with a large particle filter 2, and the second jack A medium particle filter screen 7 is inserted in 5 , and a small particle filter screen 8 is inserted in the third jack 6 . When in use, the three filter screens can intercept and filter waste chips of different diameters, and can be easily pulled out, which is conducive to later recycling.

[0020] In the above-mentioned embodiment, specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com