Perforated rod extrusion forming die

A technology of extrusion molding and rods with holes, which is applied in the field of mechanical processing, can solve the problems of product fouling, easy material accumulation, time-consuming and labor-intensive problems, and achieve the effect of avoiding product fouling, solving time-consuming and labor-intensive problems, and facilitating wrench force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

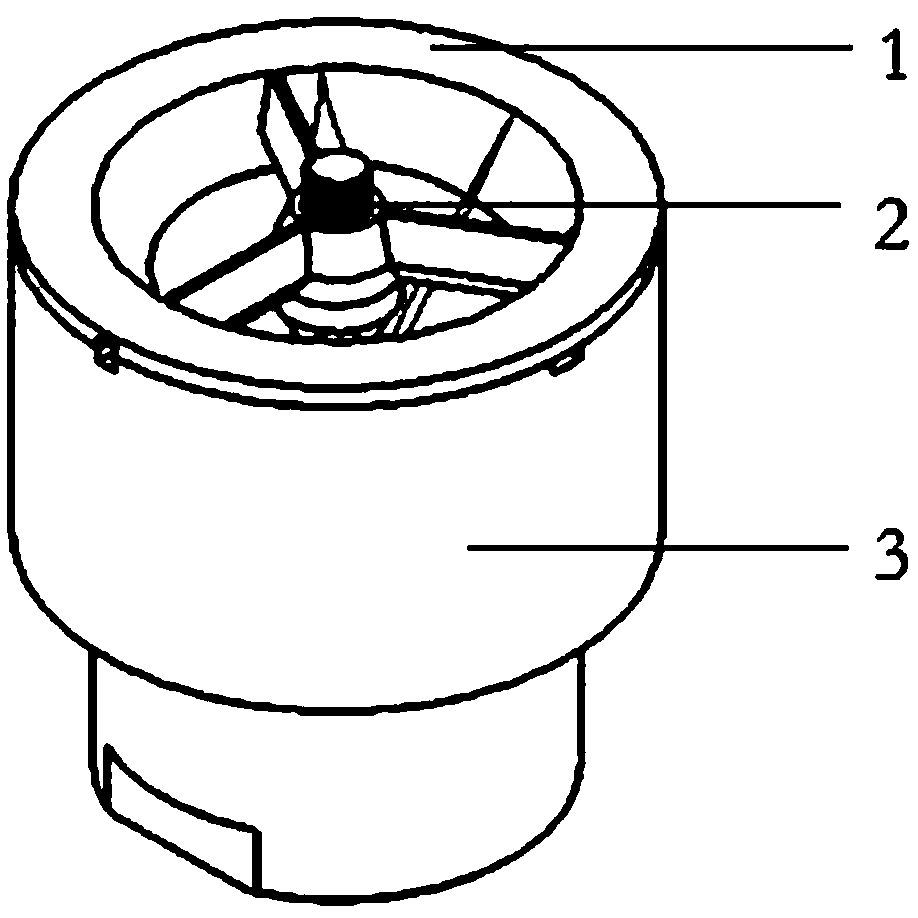

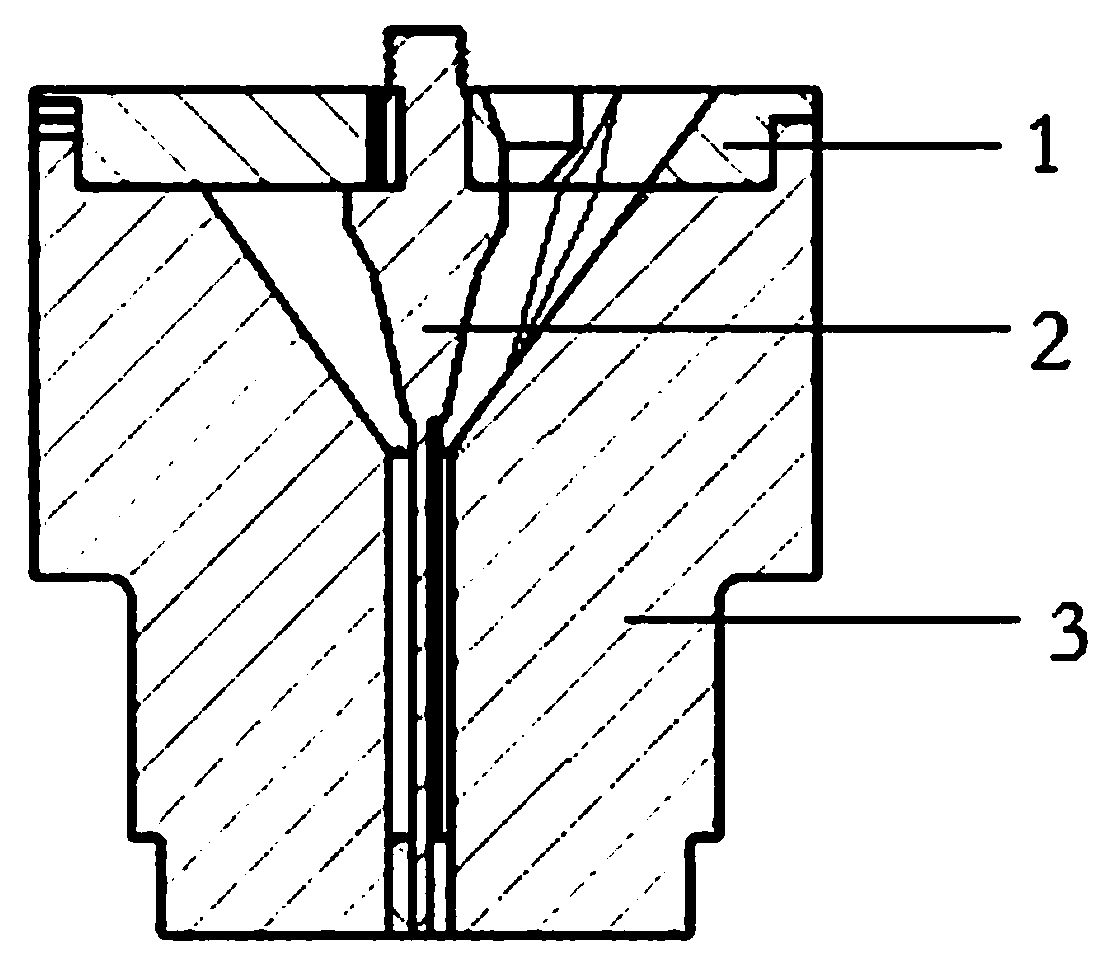

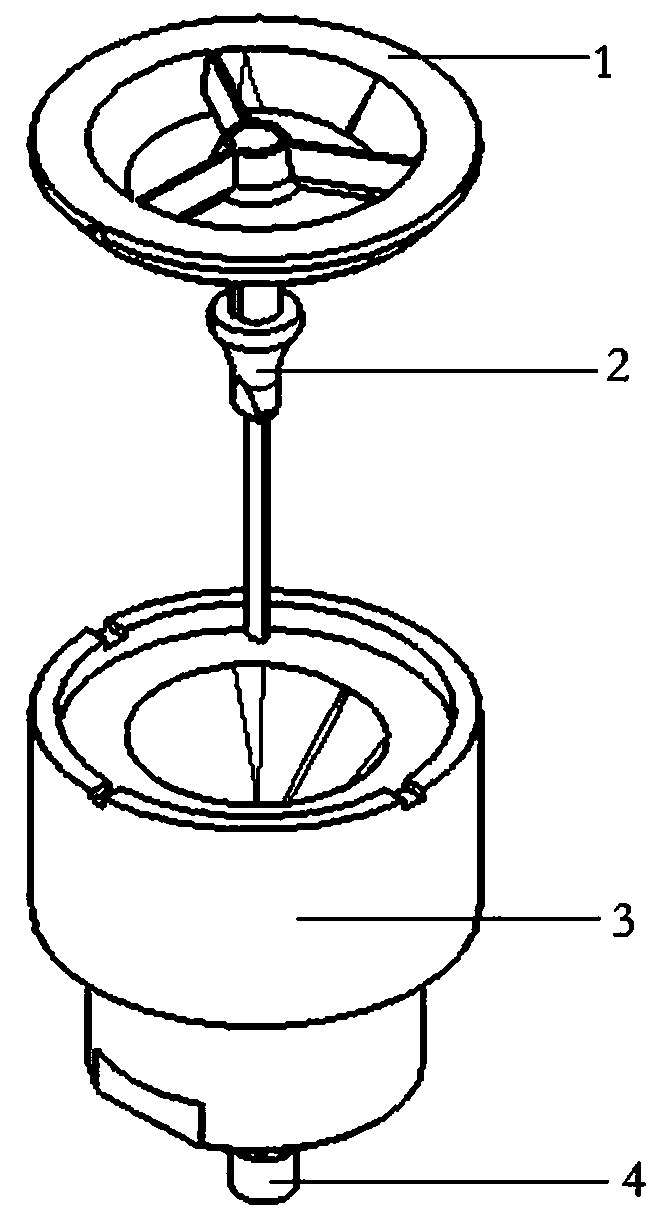

[0041] A kind of perforated rod extrusion molding die of the present invention, as Figure 1-16 , including a mandrel seat 1, a mandrel 2 and a rod forming die body 3, the mandrel seat 1 is a disc mandrel seat, and a protruding fixing part 11 is provided on the outermost side away from the direction of the center of the circle, and the mandrel seat 1 passes through The fixing part 11 is detachably fixed on the top of the rod forming die body 3 and completely covers the rod forming die body 3, the core rod 2 passes through and is assembled in the axial center of the core rod seat 1, and the core rod 2 passes through the rod The forming die body 3 is suspended and fixed inside the bar forming die body 3 through the mandrel base 1 . There is no gap between the core rod seat and the mold body, which avoids the problems that the core rod seat cannot be taken out and the mold cannot be cleaned due to material accumulated in the gap, thereby avoiding product contamination.

[0042]I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com