Combined type honing tool and method

A combined honing technology, applied in the aerospace field, can solve the problems of poor versatility, inconvenient replacement of tools with different abrasives, blind lengthening of grinding tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

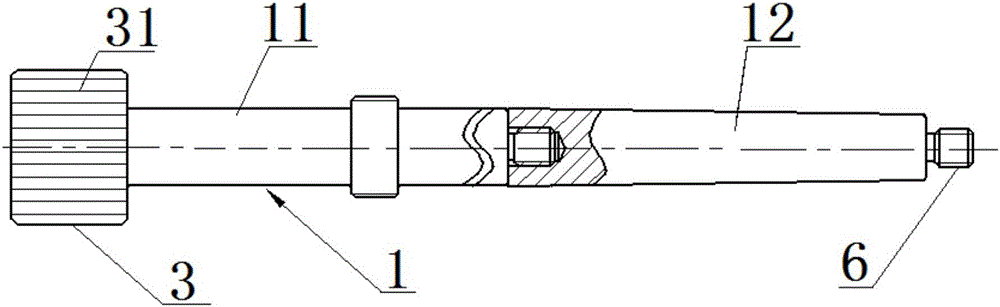

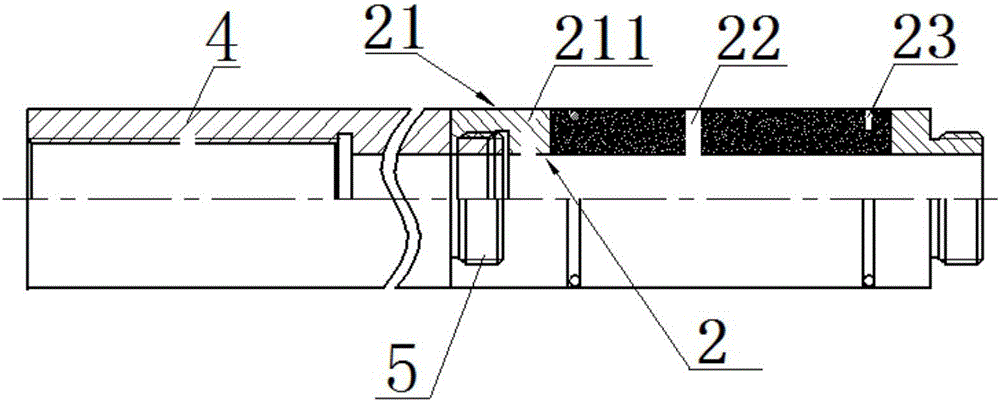

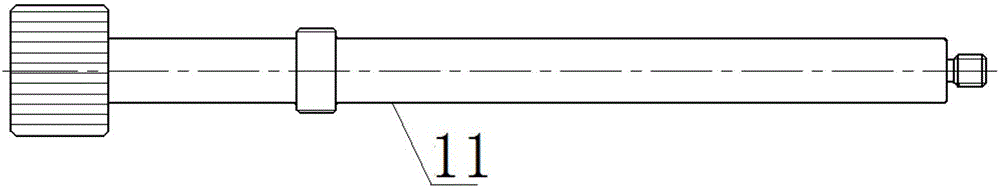

[0038] Referring to the accompanying drawings, it can be seen that a combined honing tool includes a honing tool bar 1 and a honing tool 2, and is characterized in that: it also includes a knob 3; a handle 6 is arranged at the tail of the honing tool bar 1; the knob 3 It is arranged on the honing bar 1, and a scale 31 is set on the outer surface of the knob 3; threads are respectively arranged on the outer surface of one end of the honing bar 1 and the inner surface of one end of the honing bar 2, The honing tool bar 1 and the honing tool 2 are connected by threads; the honing tool 2 includes a honing tool holder 21 and a honing tool 22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com