Machining method of double-journal thin-walled vane part

A processing method and blade technology, which is applied in the processing field of double-journal thin-walled blade parts, can solve the problems of uneven force, lower product qualification rate, and large error of journal coaxiality, etc., so as to reduce the coaxial Accuracy error, effective positioning, the effect of improving manufacturing accuracy and finished product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

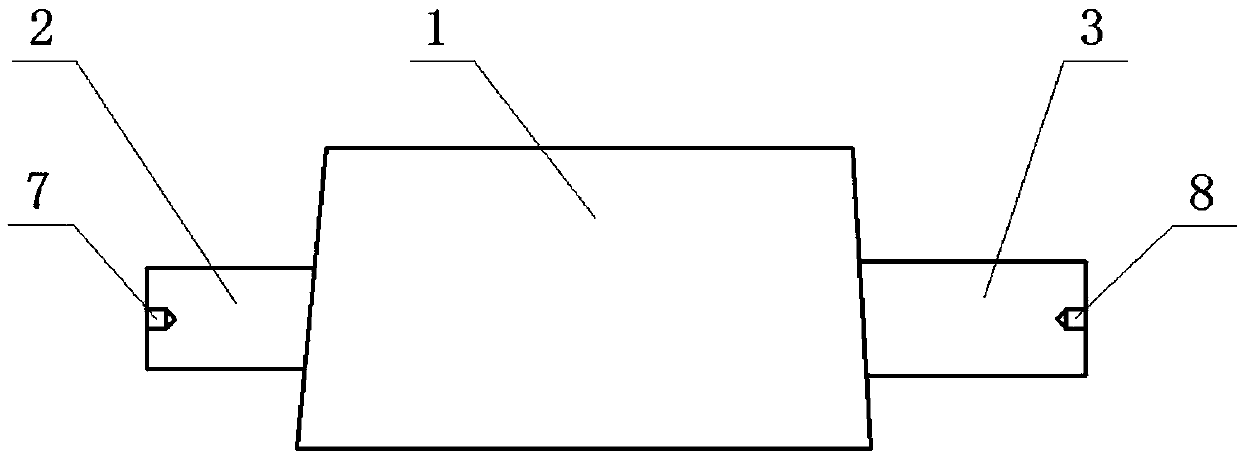

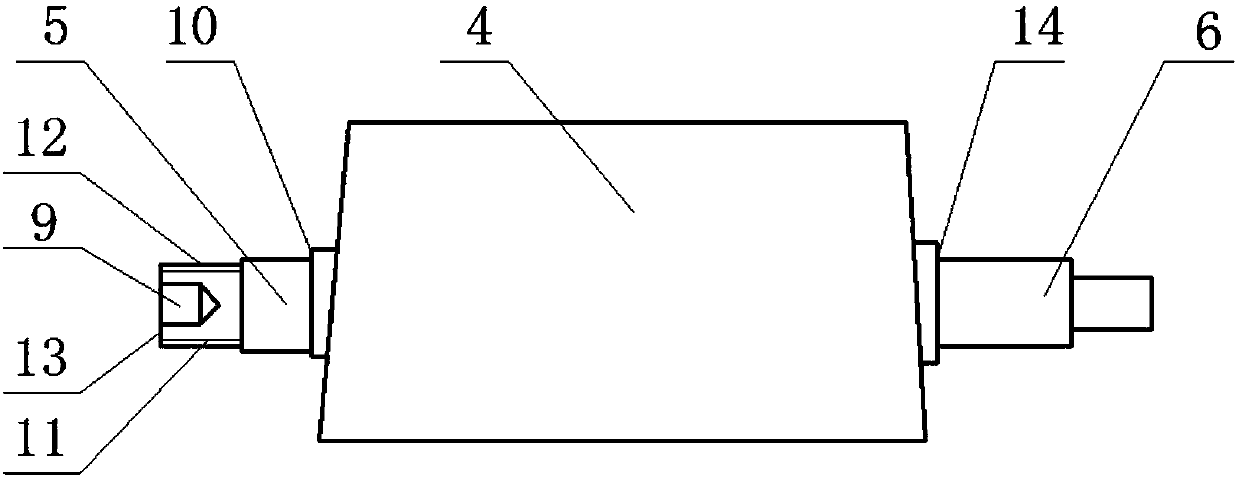

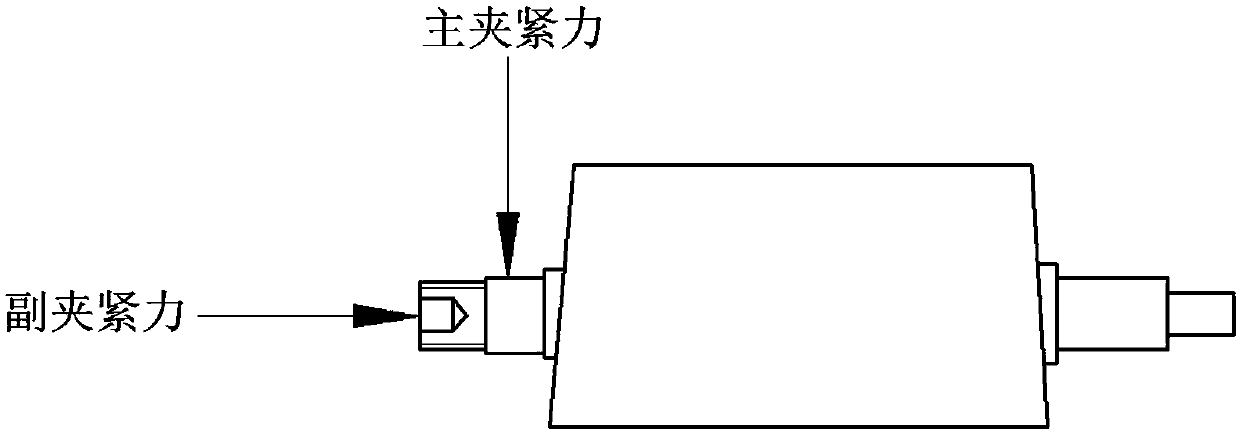

[0056] The invention provides a method for processing double journal thin-walled blade parts, such as Figure 1 to Figure 3 shown, including the following steps:

[0057] Step 1: Preparing the workpiece: using die forging to prepare the workpiece, the workpiece is composed of a thin-walled blade blank 1 and cylindrical bosses A2 and B3 arranged on opposite sides of the blade blank 1;

[0058] Step 2: Rough machining of boss A2 and boss B3: rough machining of step 1 boss A2 and boss B3 by mechanical cutting method, remove most of the materials on boss A2 and boss B3 respectively, and obtain shaft blank A and shaft Blank B;

[0059] Further, step 2 roughing the boss A2 and the boss B3 includes the following steps:

[0060] Step 1: use a milling machine to mill the end faces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com