Forming manufacturing method for waterproof silica gel sealing ring of metal card tray

A technology of waterproof silicone and its production method, which is applied in the direction of coating, etc., to achieve good sealing, solve the burr of silicone, and reduce the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

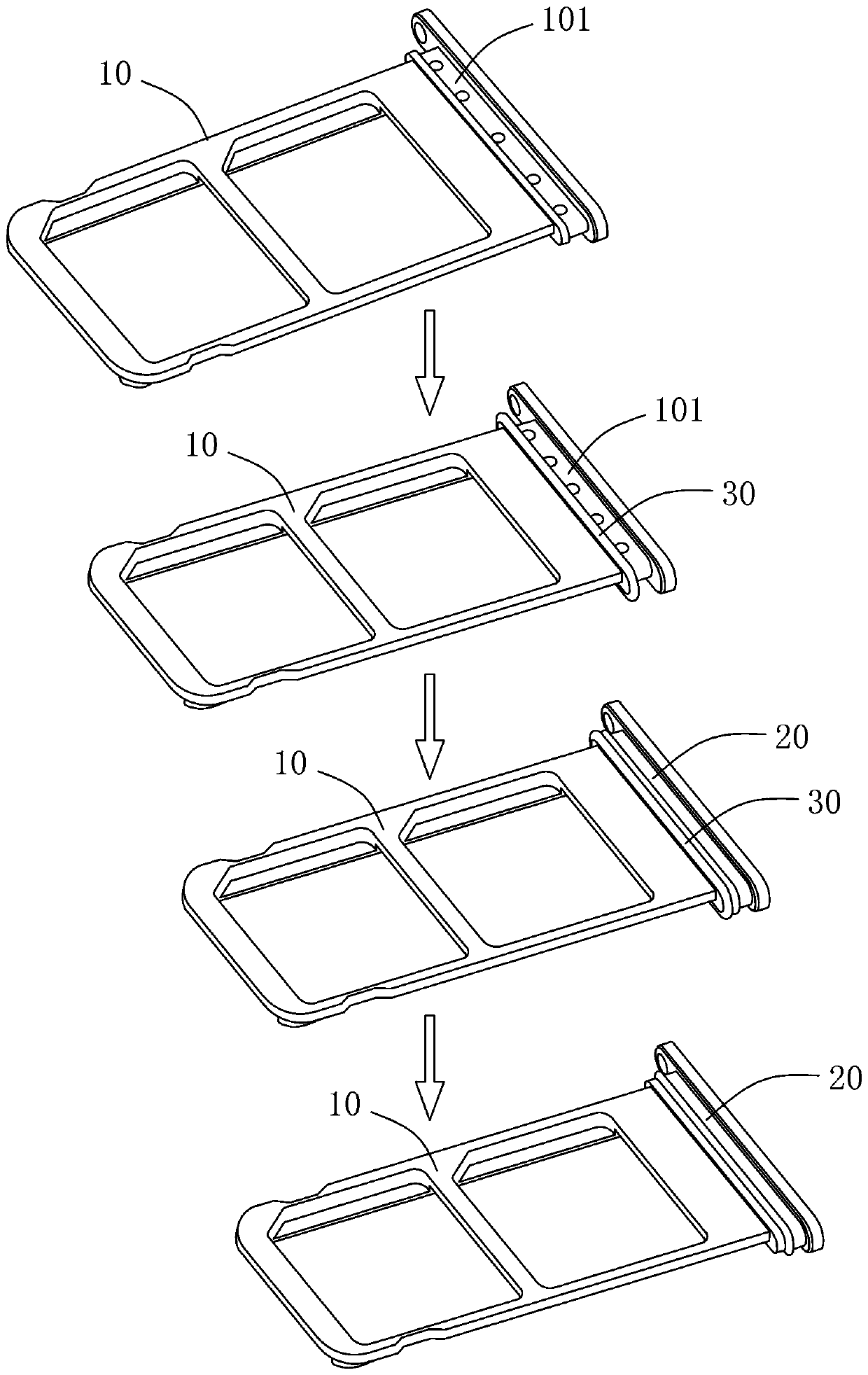

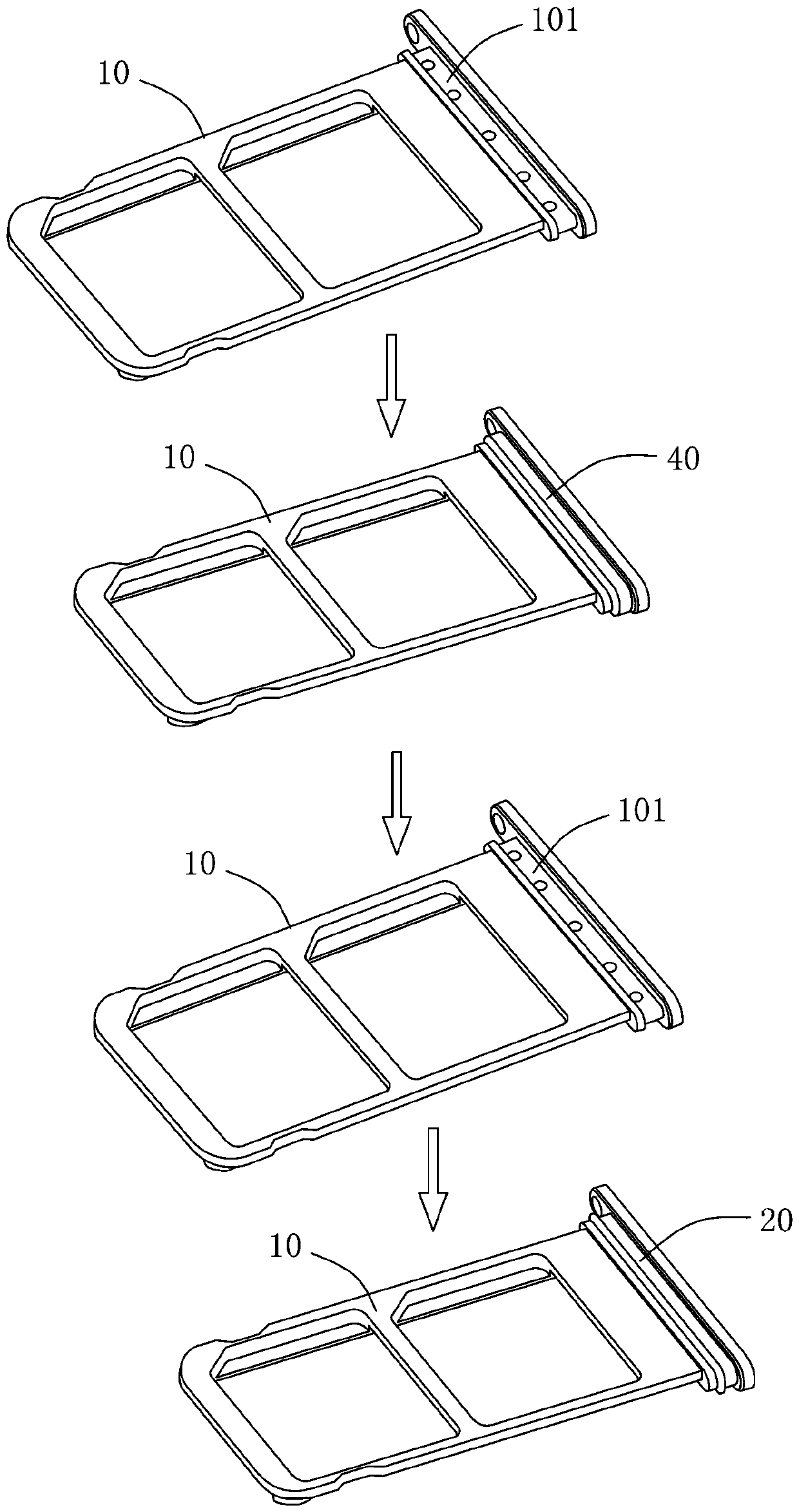

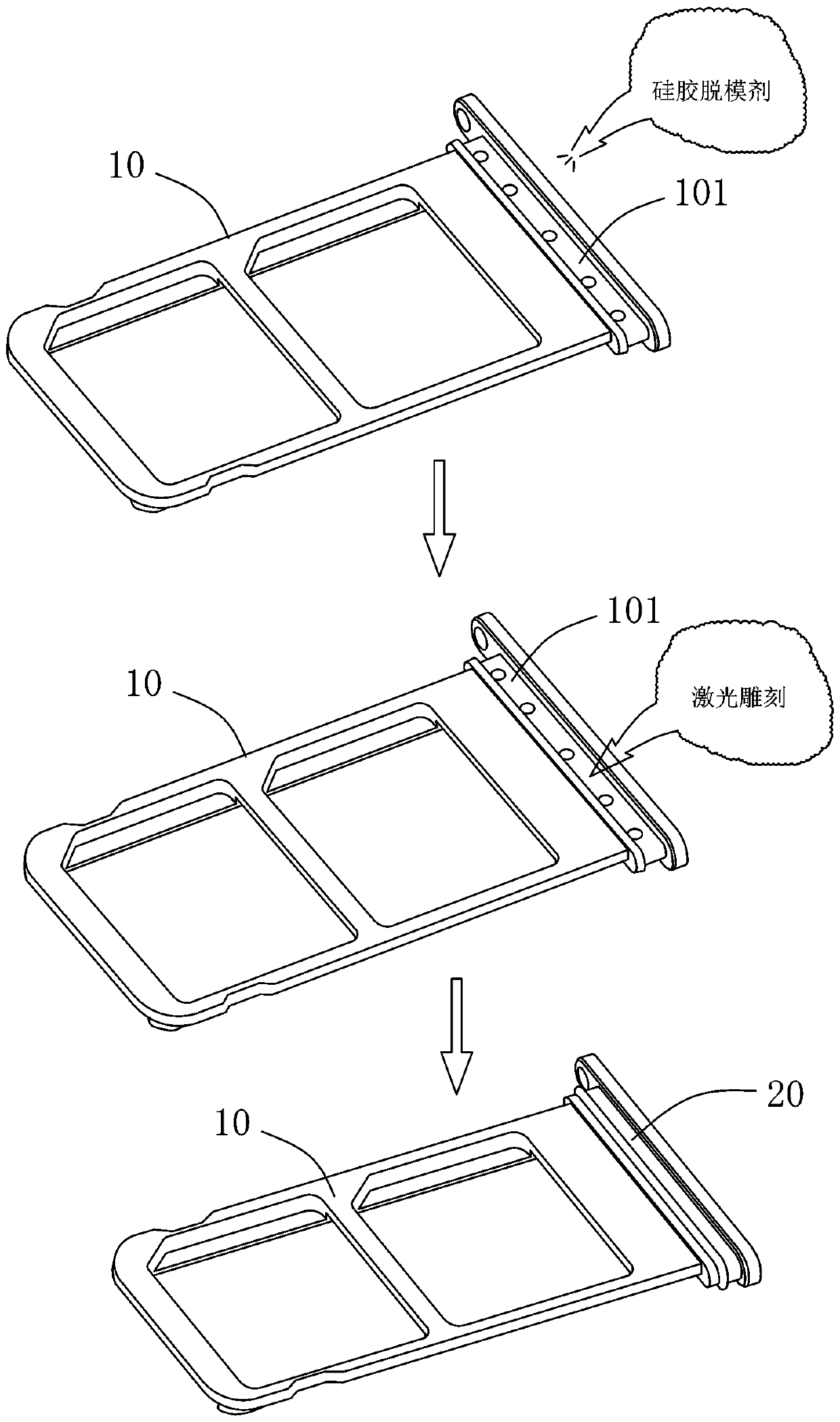

[0026] refer to figure 1 , 2 , Shown in 3, is the preferred embodiment schematic diagram of the present invention, and the present invention relates to a kind of metal card carrier waterproof silicone sealing ring forming manufacturing method, and this manufacturing method has the following steps:

[0027] S1. Provide a metal card holder 10, which has a waterproof silicone sealing ring forming area 101 and a non-forming area; the waterproof silicone sealing ring forming area 101 is properly designed to increase the adhesive force of the injection molding structure, such as holes, bumps pattern etc.

[0028] S2. At least block the junction of the waterproof sealing ring forming area 101 and the non-forming area of the metal tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com