Stern part segment constructing method

A construction method and technology of construction process, applied in ship construction, ship parts, ships, etc., can solve the problems of low production efficiency, long production cycle, high precision requirements, and achieve the effect of convenient erection and saving construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

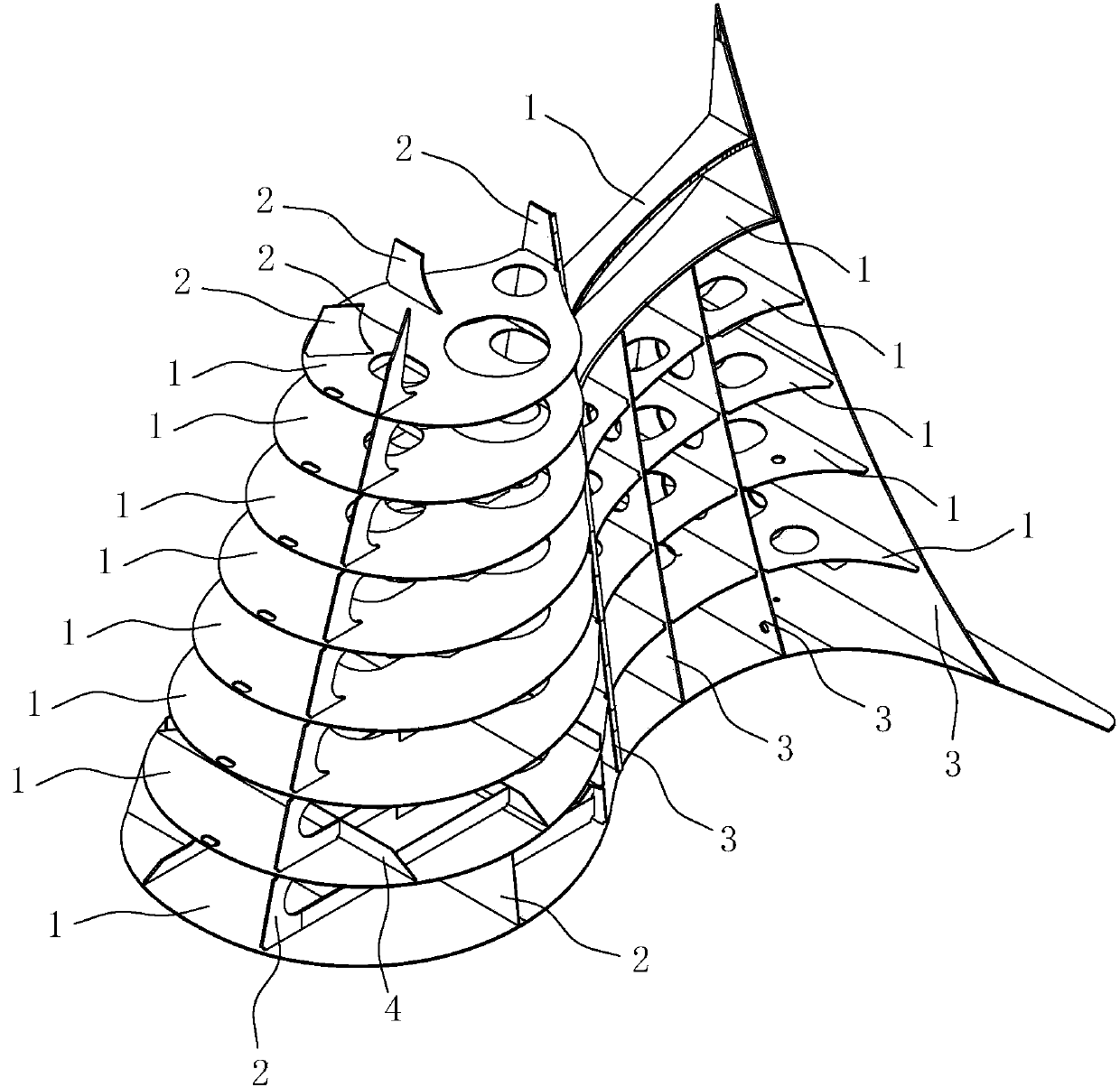

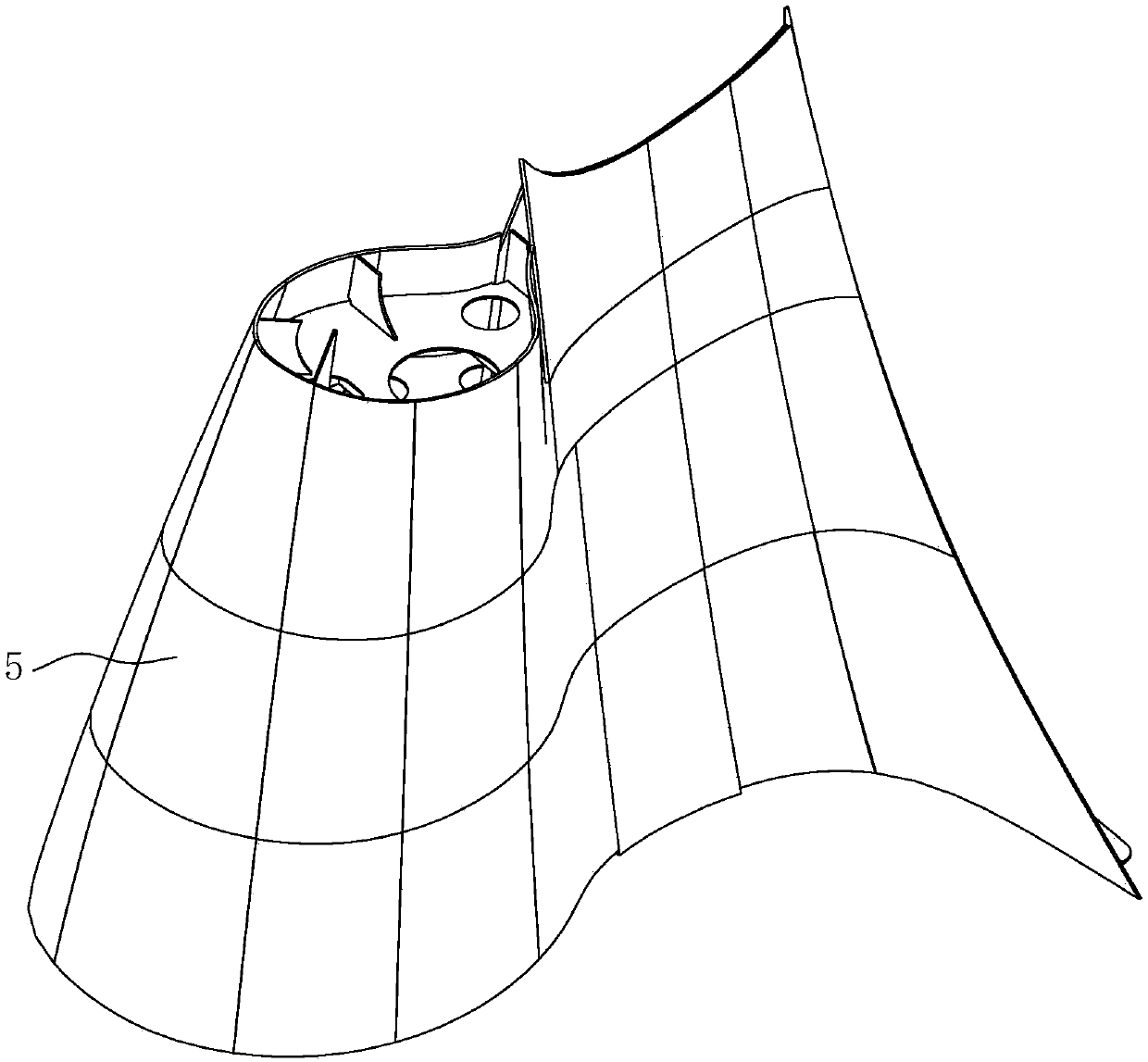

[0031] Such as figure 1 As shown, in this embodiment, the construction method of a stern section according to the present invention is characterized in that, during the construction process of the stern section, the stern section faces the bow or the stern side The rib 1 serves as the base of the platform, on which the rest of the rib 1, connecting plate 2 and platform plate 3 are hoisted to form a hull frame, and finally the outer plate 5 is hoisted on the hull frame.

[0032] During the construction of the stern section of the ship, the rib plate 1 facing the bow or stern side of the stern section is used as the platform base, and then the connecting plate 2, platform plate 3 and other ribs are built on the platform base. The plate 1 can make the construction work surface of the stern section cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com