Horizontal roller type anti-bending tempered glass production equipment and production method

A tempered glass and production equipment technology, applied in glass manufacturing equipment, glass transportation equipment, glass molding, etc., can solve the problems of high cost of automation equipment and troublesome operation, and achieve the effect of low configuration cost, simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

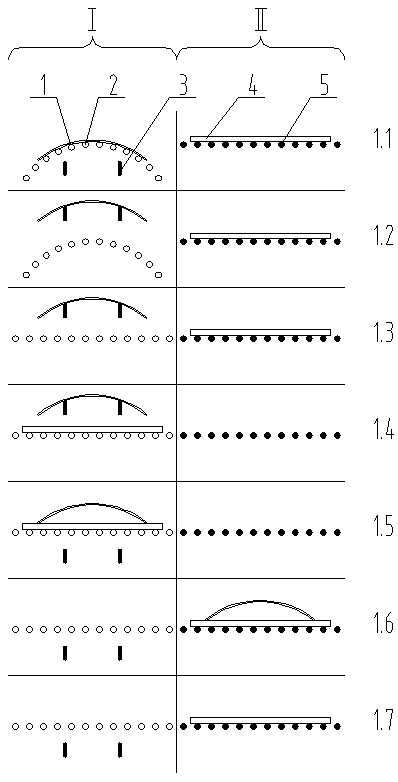

[0031] The technical solution of the present invention will be further introduced through specific implementation modes below in conjunction with the accompanying drawings.

[0032] A horizontal roller table type anti-bending tempered glass production equipment, including a heating furnace, a bending grid I, a bending grid roller table group 2 and an unloading mechanism, the bending wind grid roller table group 2 has a flattened state and a reversed bending state, and the unfolded The roller surface of the curved air grid roller table group 2 in the flat state is a horizontal plane, and the roller table surface of the curved air grid roller table group 2 in the reverse bending state is fitted with the reverse curved tempered glass; the unloading mechanism includes glass The lifting device, the unloading table II and the glass skid 4, the glass lifting device is arranged under the curved air grid roller table group 2, and is a lifting device 3 with one or more lifting ends, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap