Method and device for operating a power steering system

A technology of power steering and operation control, applied in power steering mechanism, steering mechanism, electric steering mechanism, etc., can solve the problems of overheating of electric motor, free vibration of power steering mechanism, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

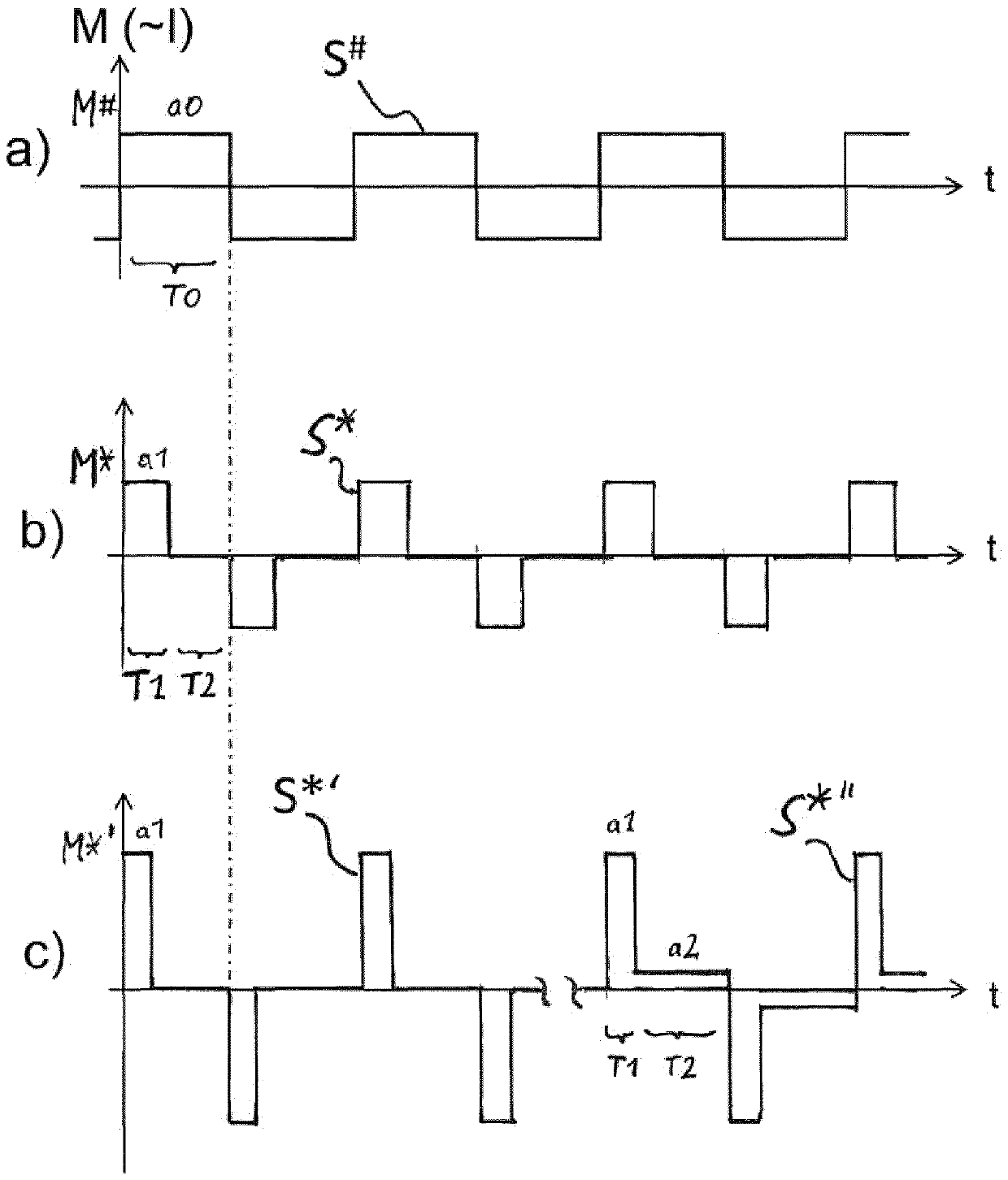

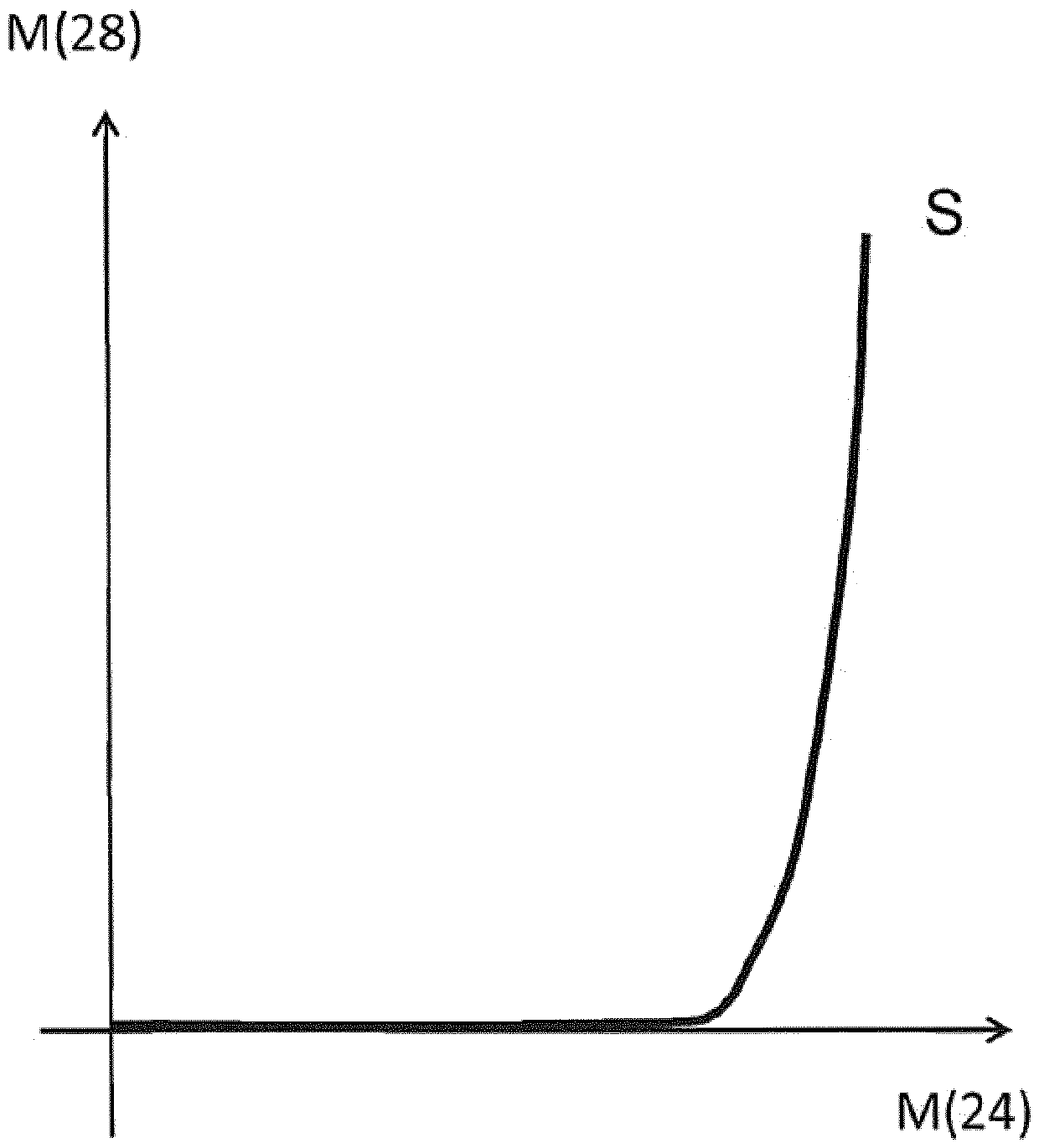

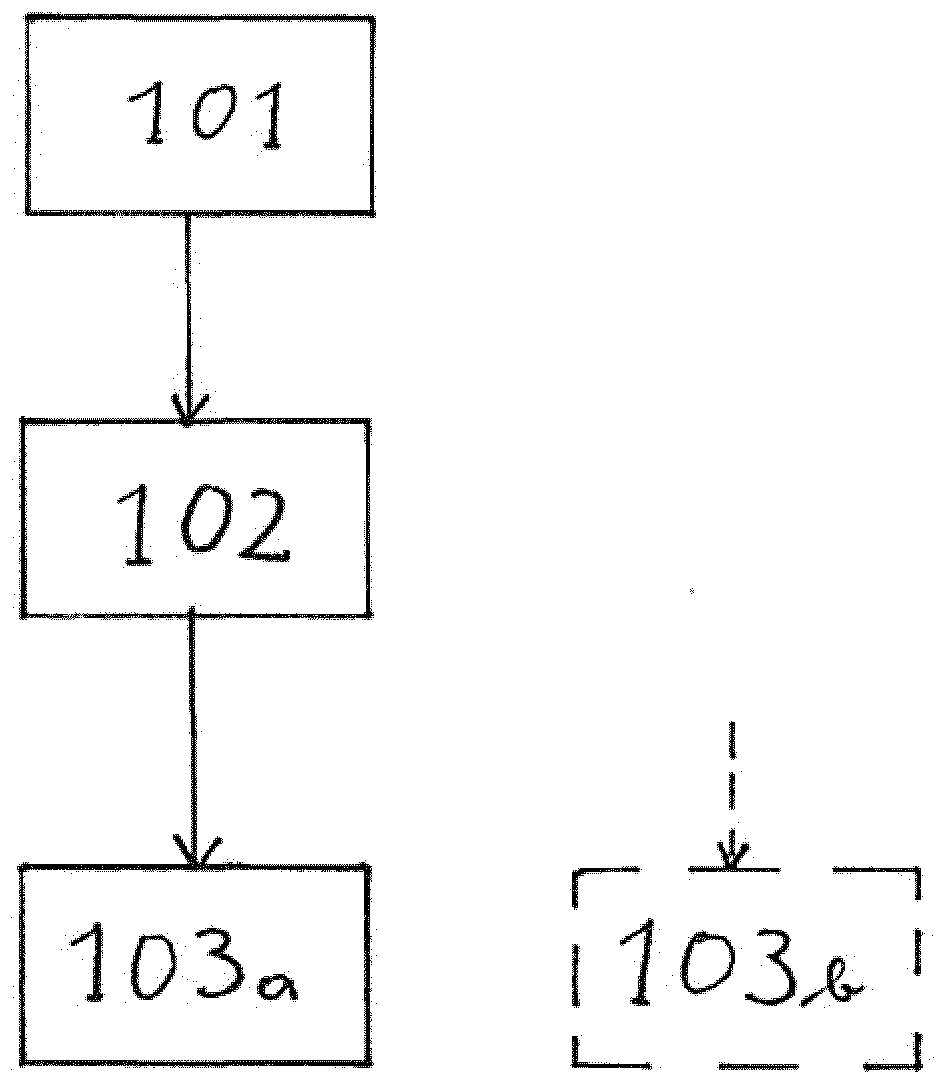

[0022] figure 1 The structure of a power steering system 10 for a motor vehicle is shown schematically. The power steering has in particular a steering handle 12 designed as a steering wheel, an electric motor 16 and a superposition unit 14 which superimposes a motor torque 26 applied by the electric motor 16 to a predetermined manual torque 24 . The superposition unit 14 is realized here by a superposition gear, which at the output provides the resultant acting torque 28 for the actual steering gear, which comprises, for example, a toothed rack 18 into which the steering pinion meshes. in the article. The displacement of the rack ultimately leads to a deflection of the articulated wheel 20 .

[0023] To actuate the electric motor 16 , a device designed as a controller 22 is arranged which generates an operating control signal S or supplies a corresponding motor current during normal driving operation.

[0024] In order to effectively prevent freezing of the electric motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com