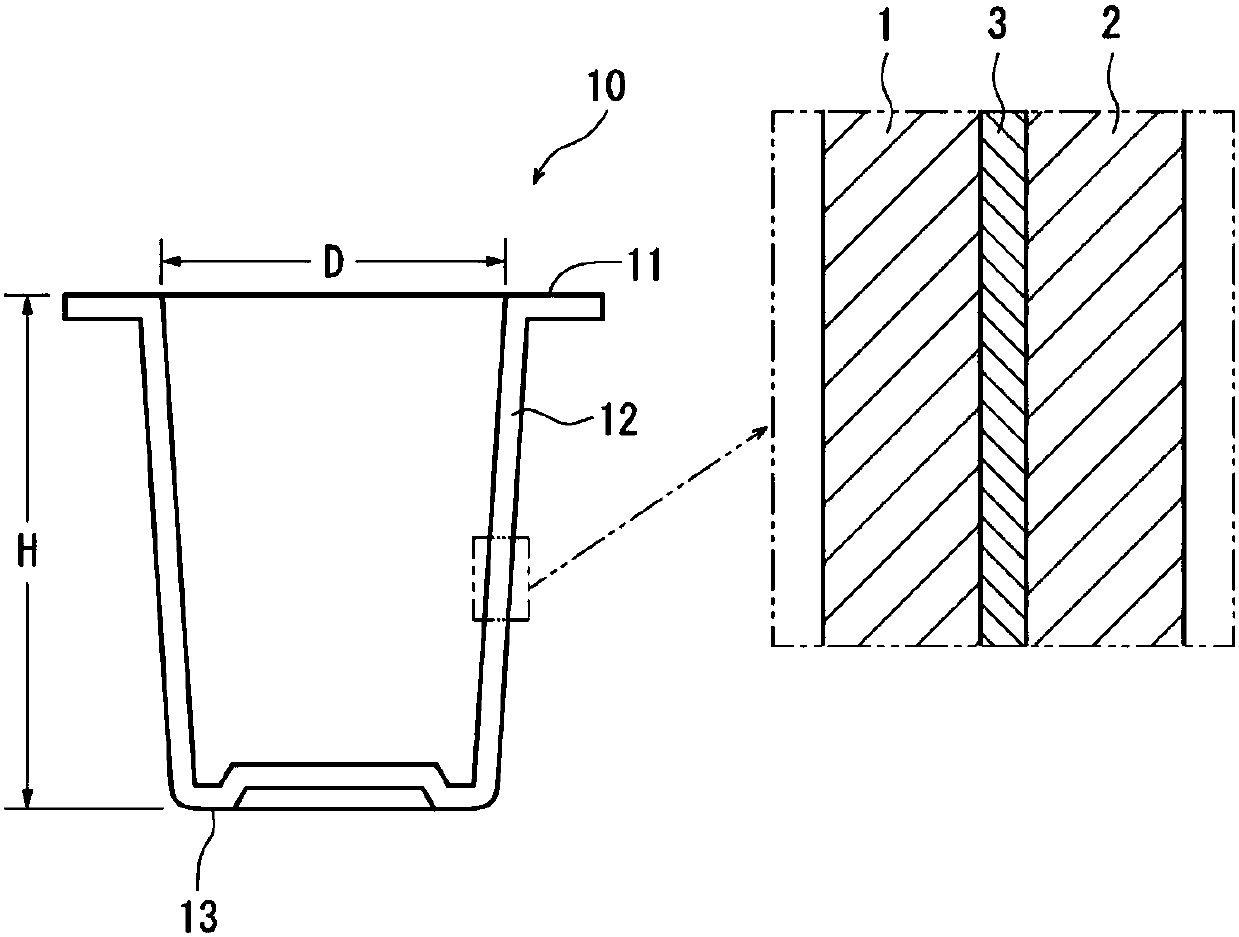

Cup-type multilayered container

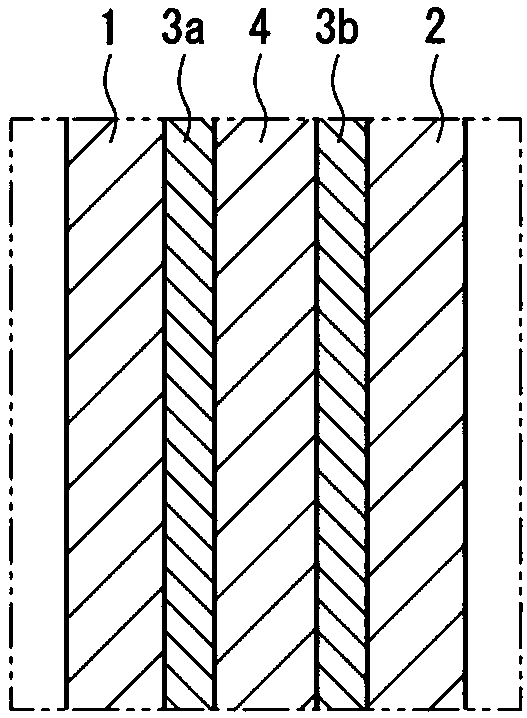

A container and polyester resin technology, which is applied in the field of cup-type multi-layer containers, can solve the problems such as the loss of transparency of polyester resin, and achieve the effects of preventing interlayer peeling, excellent mechanical strength, and excellent interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

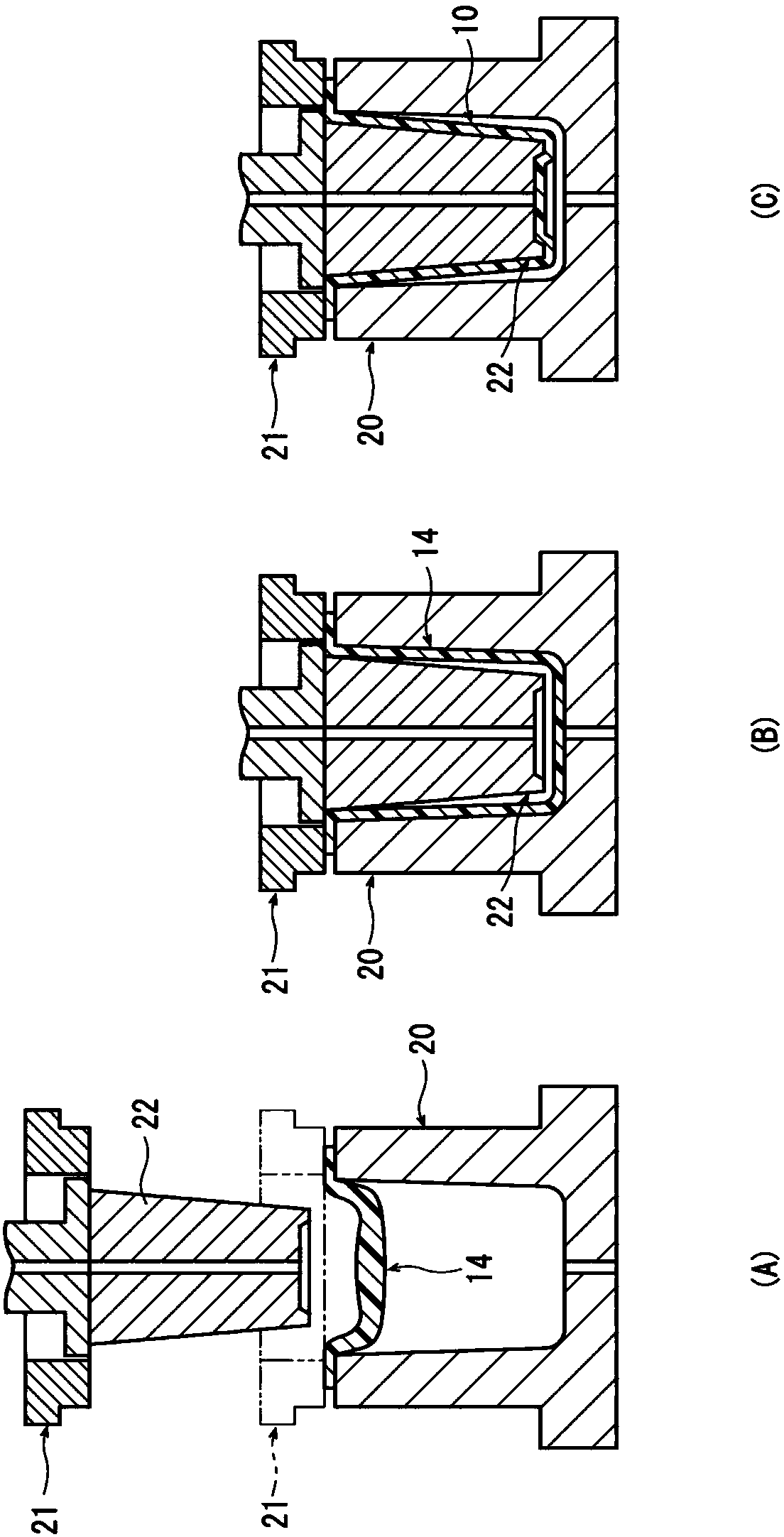

[0127] A multi-layer sheet was made by using PET to form the inner and outer layers, dry blending APET1 and PA together at a ratio of 70:30 to form the middle layer, and setting the temperature of the molding machine at 280°C.

[0128] The sheet was made to have a thickness of 1.2 mm, and the intermediate layer was 10% by weight of the entire sheet. Next, the sheet was heated again at 100° C. to form a cup, and thus a multilayer container having a drawing ratio of 1.67 and an inner volume of 350 cc was produced. The resulting container was measured for side haze, occurrence of delamination, and oxygen barrier property according to the methods described above.

[0129] Furthermore, the dried APET1 was fed into a hopper of an injection molding machine, and injection molded while setting the temperature of the cylinder at 280° C. to obtain an injection molded plate having a size of 90×90×1.5 mm. The injection-molded plate was uniaxially stretched 3 times by the above method to o...

Embodiment 2

[0131] By using APET1 as a base material, the granular masterbatch resin (MB1) which contained an oxidation catalyst in the resin composition in the amount of 500 ppm of metal conversion was prepared by the said method. Here, the temperature of the barrel was maintained at 280°C.

[0132] By using a multilayer sheet-forming machine, a multilayer container and a stretch sheet were fabricated in the same manner as in Example 1, except that an intermediate layer was formed by using a dry blend of MB1 and PA in a ratio of 70:30. Then measure their properties.

Embodiment 3

[0134] A multilayer container was produced in the same manner as in Example 1 except that APET2 was used instead of APET1, and its properties were measured.

[0135] In addition, a stretched sheet was produced in the same manner as in Example 1, except that dry APET2 was supplied to the hopper of an injection molding machine to form an injection-molded sheet thereof. The refractive index of the produced stretched sheet was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com