Method for producing components from strip-shaped semi-finished products by means of a coil machine

A technology for semi-finished products and components, which is applied in data processing applications, instruments, calculations, etc., and can solve problems such as no traceability and no process transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

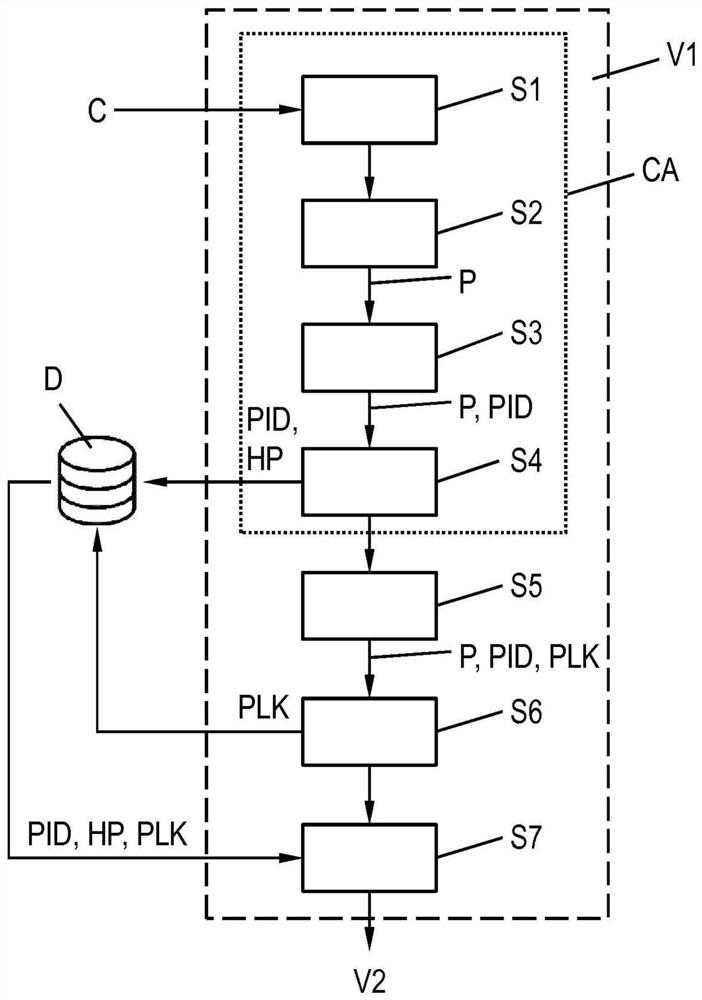

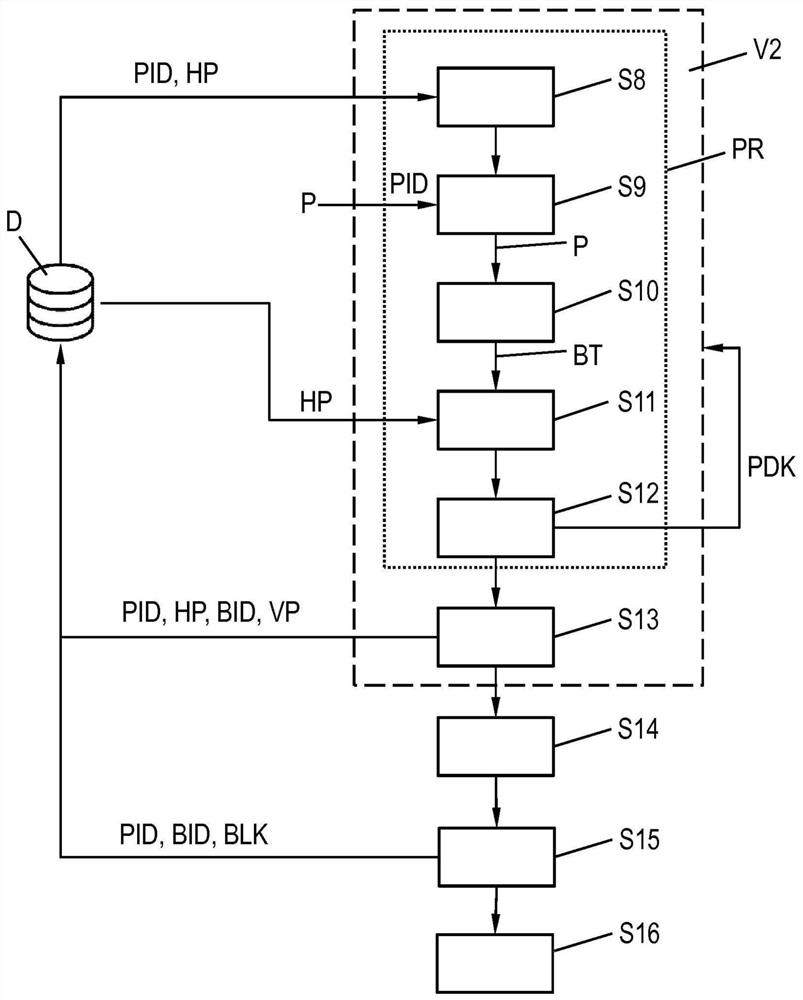

[0055] figure 1 The sequence of the first sub-method V1 of the method for producing a vehicle component BT or the first part of the method is briefly shown. Said sub-method V1 involves the manufacture of a slab P from a metal strip by means of a coil machine CA.

[0056] In method V1, in a first step S1 at the coil machine CA, the slab precisely determines at least one component parameter of the metal strip unwound from the pre-provided coil C.

[0057] In a second step S2, the metal strip is separated into slabs P by means of a coil machine CA. This can be done, for example, by extruding sections of the unrolled metal strip of the coil C.

[0058] In step S3 , the slab that has been separated or still to be separated from the metal strip is provided with a personal identification (part ID, which can also be referred to as slab ID here) PID. Step S3 can be performed before, during or after step S2. The part ID, ie PID, can be applied by laser marking.

[0059]In step S4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com