Warehousing retroactive method and system of cigarette finished products

A warehouse management system and finished product technology, which is applied in the field of traceability of cigarette finished products, which can solve the problems of inability to trace pallet information, no information system, and increase the amount of traceability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Explanation of relevant background technology:

[0055] 1. Every 20 finished cigarettes is a pack, every 10 packs is a pack, every 50 packs is a pack, and every 30 packs is a tray;

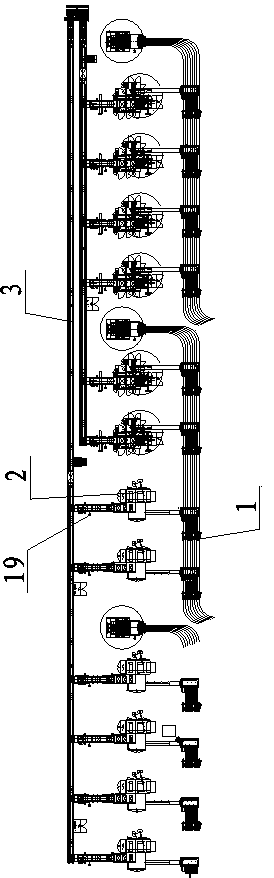

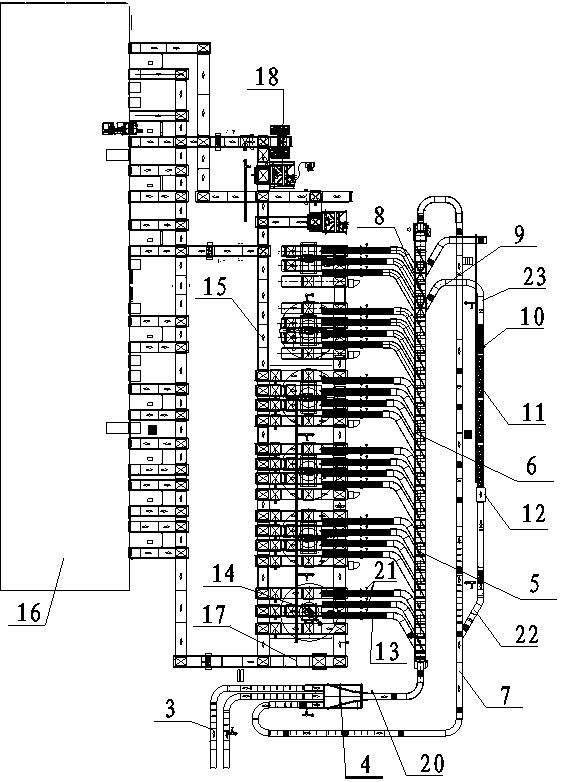

[0056] 2. Pallet introduction: The pallet is a plastic pallet of 1000×1250×150mm, and RFID code carrier (ie, electronic label) is installed on the pallet. RFID is used to record the 1# project code of 30 cigarettes in this pallet; this kind of pallet and 10 pieces of cigarettes per layer, stacking 3 layers is the industry standard for finished product palletizing in the tobacco industry;

[0057] 3.1# Project Introduction: The cigarette production and operation decision-making management system is called "No. 1 Project" in the industry. It is a computer information management system; the system passes the "One scan and two scans" (cigarette products are coded when they are off-line in industrial enterprises, codes are scanned when they leave the warehouse, and codes are scanned for commerc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com