Steel coil stocking crane control system and control method

A technology of control system and crane, applied in the direction of load hanging components, elevators in buildings, safety devices, etc., can solve problems such as lack of perfect safety monitoring and computer management system, inability to meet crane operation control, and low production efficiency of enterprises , to achieve the effect of reducing the probability of human error, realizing intelligent warehouse management, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

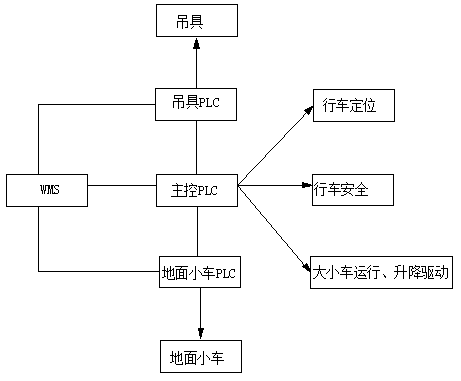

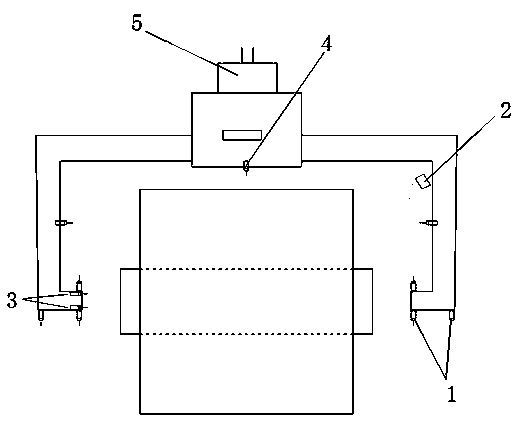

[0019] see figure 1 with 2 , the present invention relates to a steel coil storage crane control system, including a WMS system and a crane. The crane includes a main control PLC, a spreader, a spreader PLC, a ground trolley, and a ground trolley PLC. , driving safety and operation of large and small vehicles and lifting drive, the spreader grasps and places steel coils through the spreader PLC, and the steel coils are equipped with RFID tags, and the RFID tags are attached to the outer surface of each incoming cargo. , the content is the ID number of the goods and the information of the goods, such as the type, model, storage time, etc. of the goods. The spreader and the ground trolley are respectively equipped with RFID reader-writers 2, and the WMS system, the main control PLC, the spreader PLC and the ground trolley PLC realize data exchange and process control through communication.

[0020] After the main control PLC receives the target position of the WMS system, it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com