A Forming Method for Improving the Wall Thickness Distribution of Superplastic Formed Special-shaped Cylinders by Pre-Reverse Deformation

A superplastic forming and anti-deformation technology, applied in the field of precision sheet metal processing, can solve the problems of high cost, poor integrity of parts, difficult control of shape accuracy, etc., to shorten production cycle, improve efficiency, and improve uneven wall thickness and thinning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

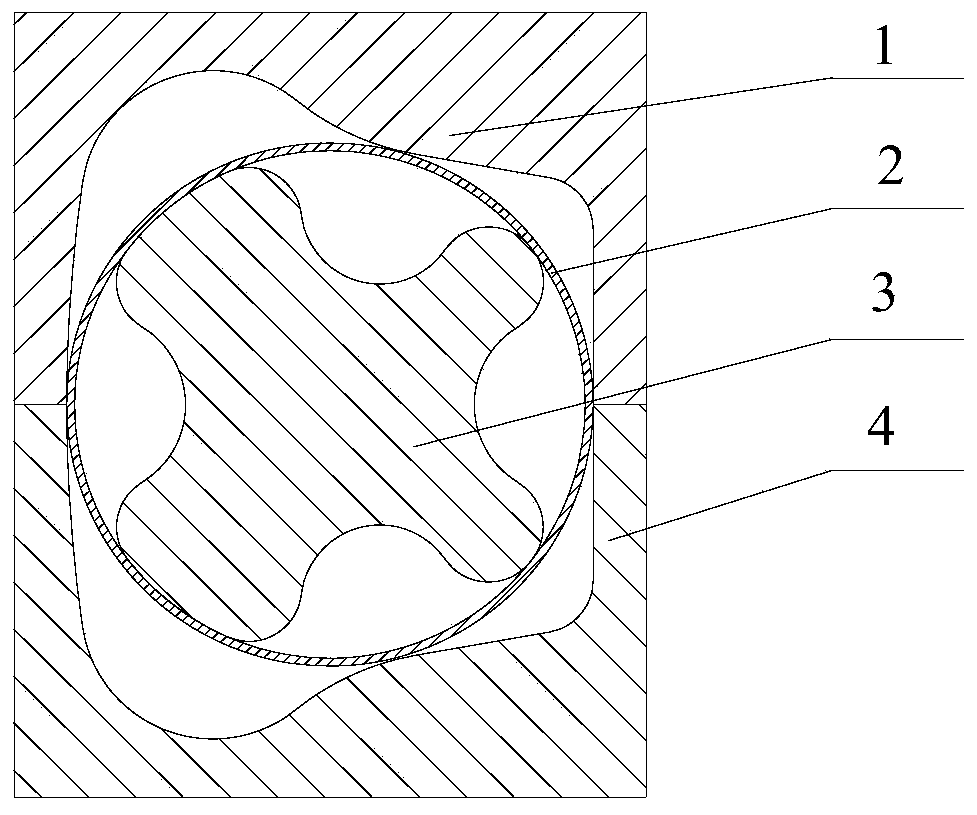

[0032] The preferred embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] Forward superplastic forming refers to the method of applying positive gas pressure to shape parts at a certain temperature and certain deformation rate. Pre-reverse deformation is to apply gas pressure in reverse and then apply gas pressure in a positive direction. Such as Figure 6 As shown, a forming method for improving the wall thickness distribution of superplastic formed special-shaped cylinders through pre-reverse deformation, the specific steps are as follows:

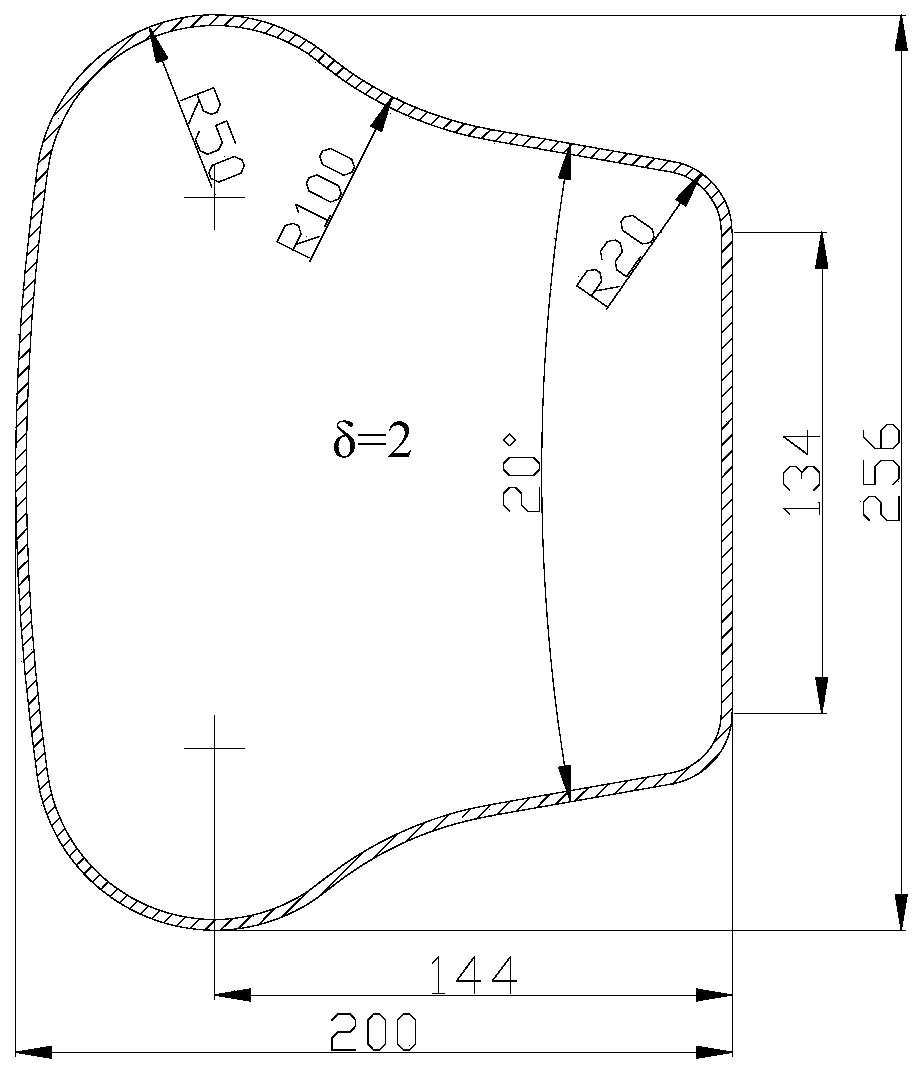

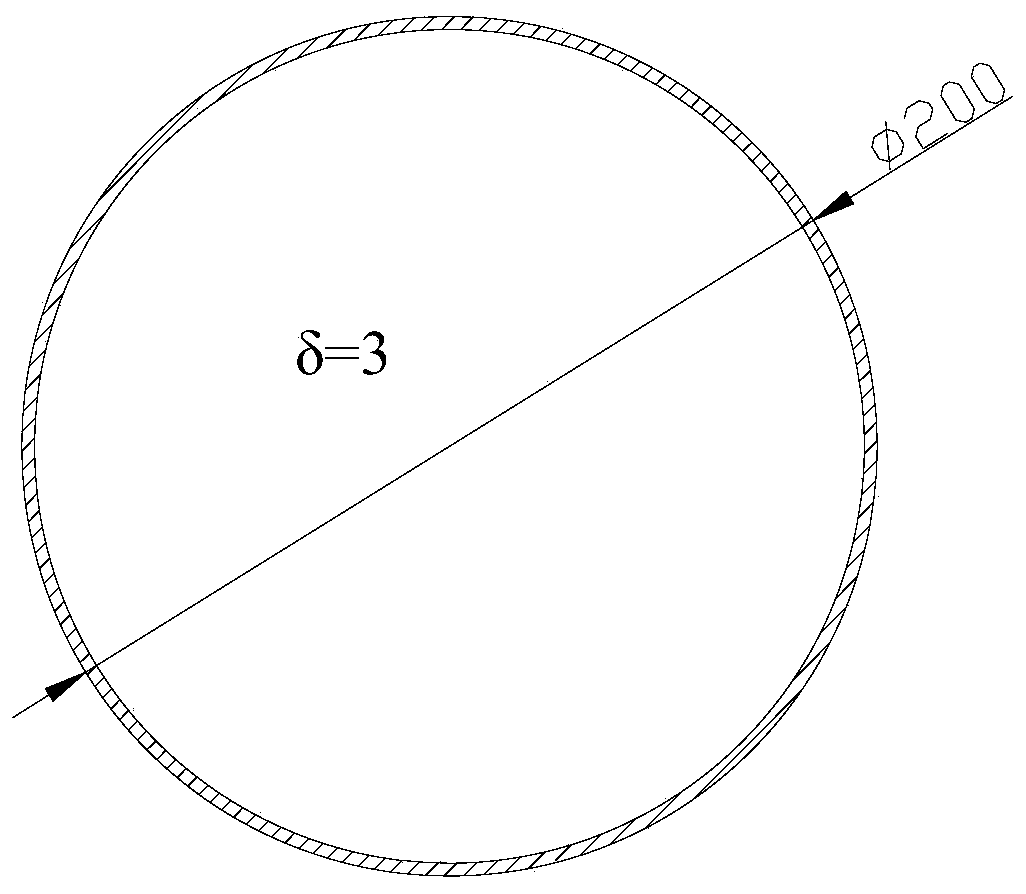

[0034] (1) According to the external dimensions and thickness of the aluminum alloy special-shaped cylinder, the external dimensions and thickness of the aluminum alloy special-shaped cylinder blank are determined; the perimeter of the section of the aluminum alloy special-shaped cylinder blank Lp=the section perimeter of the aluminum alloy special-shaped cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com