Machining tool for circular frame of vibrating screen

A sieve circular and frame technology, which is applied in the processing tooling field of the vibrating screen circular frame, can solve the problems of inconvenient processing, deformation of the bottom of the circular frame, etc., and achieve the effect of improving processing efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments are described in detail in conjunction with the accompanying drawings,

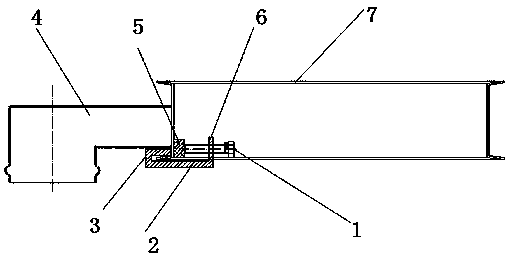

[0008] A processing tool for the circular frame of a vibrating screen, which includes a base plate 2, a ┌-shaped inverted plate 3 is provided on one side of the base plate, and a vertical plate 6 is provided on the other side of the bottom plate, and screw holes are opened on the vertical plate. Bolts 1 are assembled in the screw holes; the curved plate 5 matches the inner radian of the circular frame 7 .

[0009] When the present invention is in use, at the position where the discharge port 4 needs to be welded, first use the ┌-shaped inverted plate on the bottom plate to block the bottom edge of the circular frame of the vibrating screen, and then use bolts to fix the arc-shaped plate. Make the arc-shaped plate withstand the inner ring of the circular frame of the vibrating screen, so that the strength of the circular frame at the part of the discharge port that needs to be processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com