Suction disc device and element transfer method

A suction cup and component technology, applied in the field of suction cup devices with patterned conductive layers, can solve the problems of high cost, increased cost, unfavorable use of mechanical picking methods, etc., and achieves the effect of avoiding static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

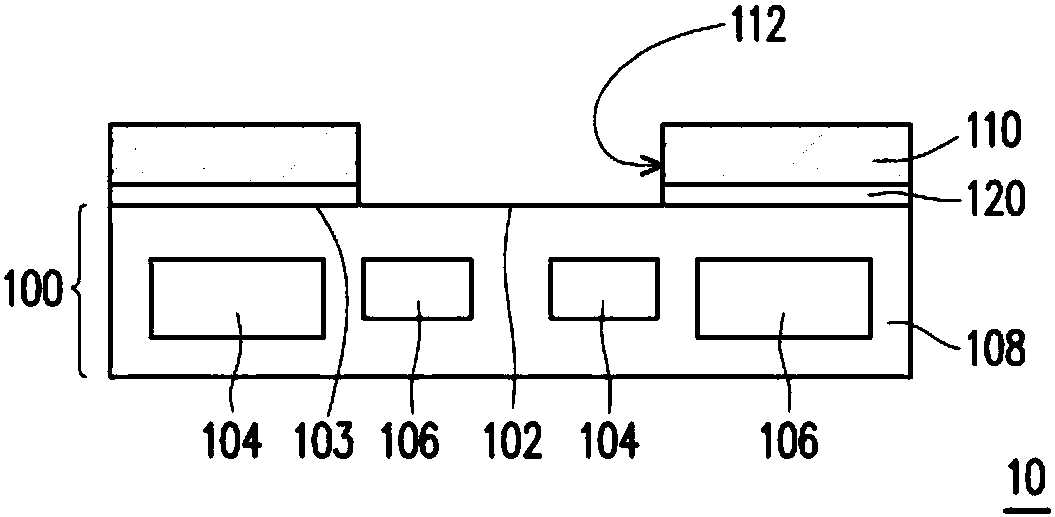

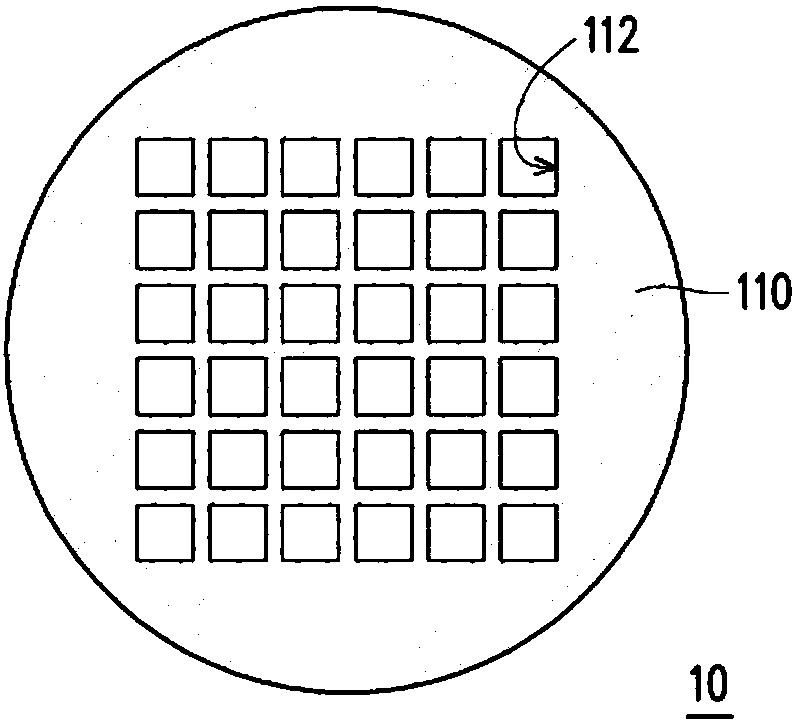

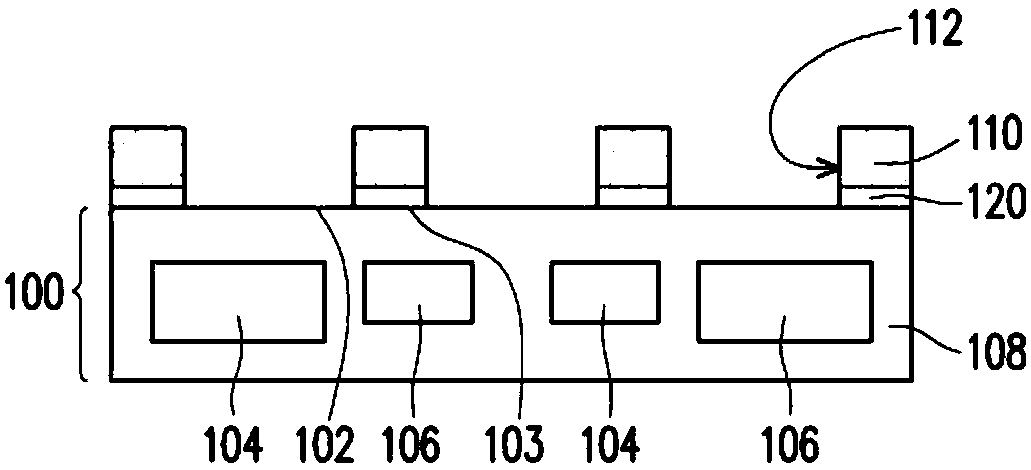

[0021] Figure 1A is a schematic cross-sectional view of a suction cup device according to an embodiment of the present invention, and Figure 1B It is a schematic top view of a suction cup device according to an embodiment of the present invention. Please also refer to Figure 1A and Figure 1B , in this embodiment, the chuck device 10 includes an electrostatic chuck 100 and a patterned conductive layer 110 . The electrostatic chuck 100 , for example, includes at least one positive electrode 104 , at least one negative electrode 106 , and an insulating layer 108 surrounding the positive electrode 104 and the negative electrode 106 , wherein charges are distributed in the insulating layer 108 . The positive electrode 104 and the negative electrode 106 are arranged in such a way that the positive and negative electrodes intersect each other. In this embodiment, the electrostatic chuck 100 includes, for example, a plurality of positive electrodes 104 and a plurality of negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com