GIS bus mounting equipment

A technology for installing equipment and busbars, which is applied in the field of GIS busbar installation equipment, can solve problems such as long working hours, high labor intensity, and a large amount of manpower, and achieve the effects of reducing work intensity, improving work efficiency, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

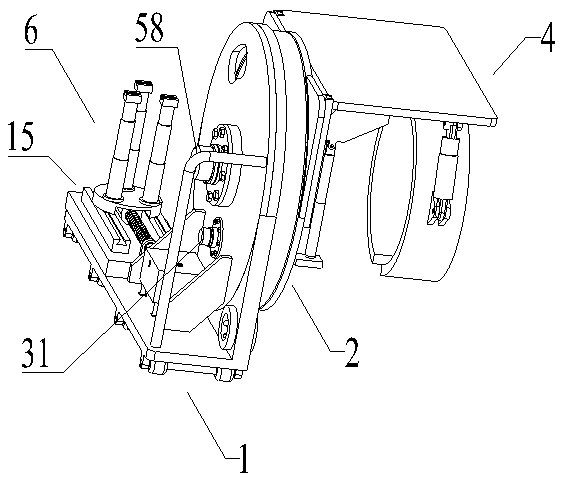

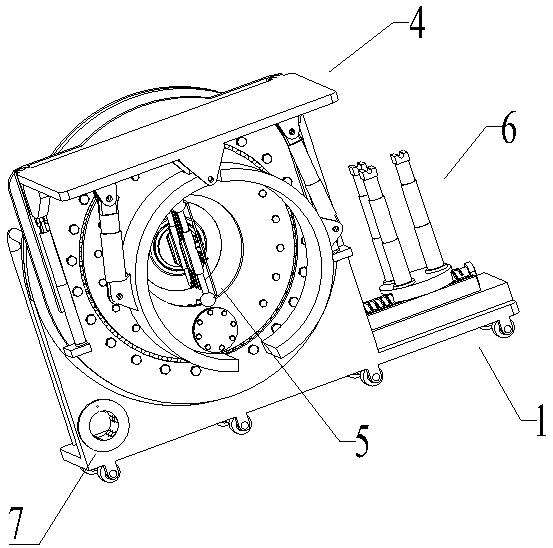

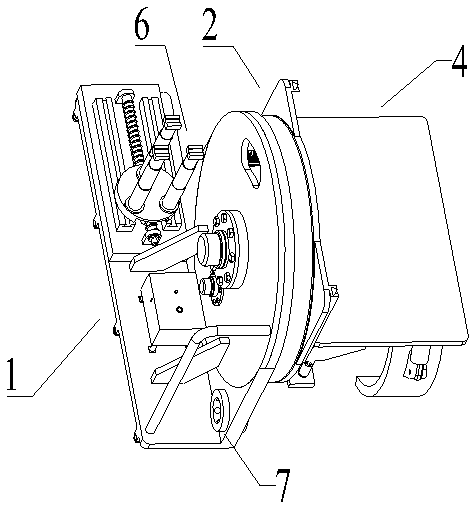

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the GIS busbar installation equipment includes a frame device 1, a turntable 2, a rotating power device 3, a chuck device 4, a cleaning device 5, a conductive rod support structure 6 and a conductive grease coating device 7.

[0057] Such as Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the frame device 1 includes a mounting plate 11, a bottom plate 12, a gear positioning plate 14, a conductive rod driving device 15 and a connecting rod 16, and the mounting plate 11 includes a mounting plate body 111, a cleaning mounting hole 112, and a rotating motor mounting seat 113, conductive rod mounting hole 114, conductive grease mounting hole 115 and frame positioning seat 116, the cleaning mounting hole 112 and the rotating motor mounting seat 113 are arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com