Automatic rock wool cutting machine

A cotton cutting machine, automatic technology, applied in the direction of metal processing, etc., can solve the problem of inconvenient grinding of the blade 41, achieve the effect of improving cleaning effect, reducing noise, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

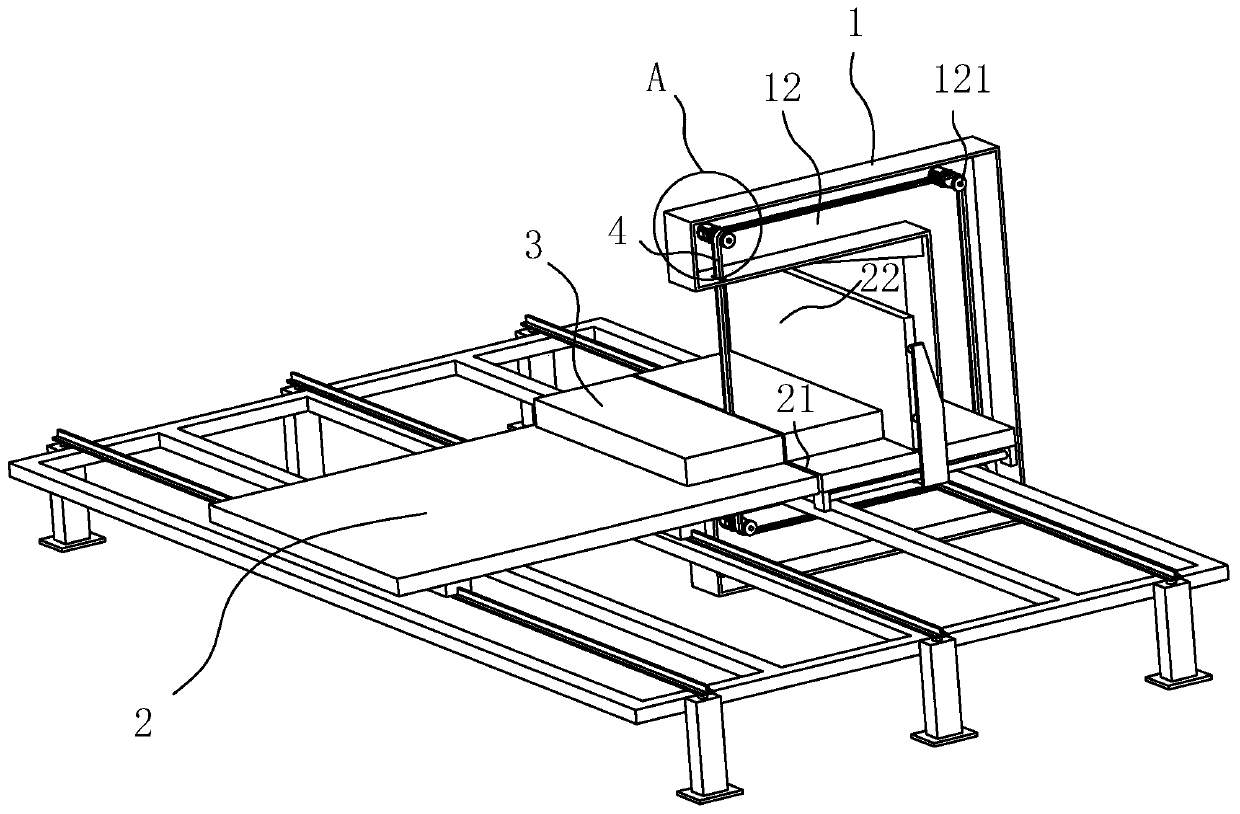

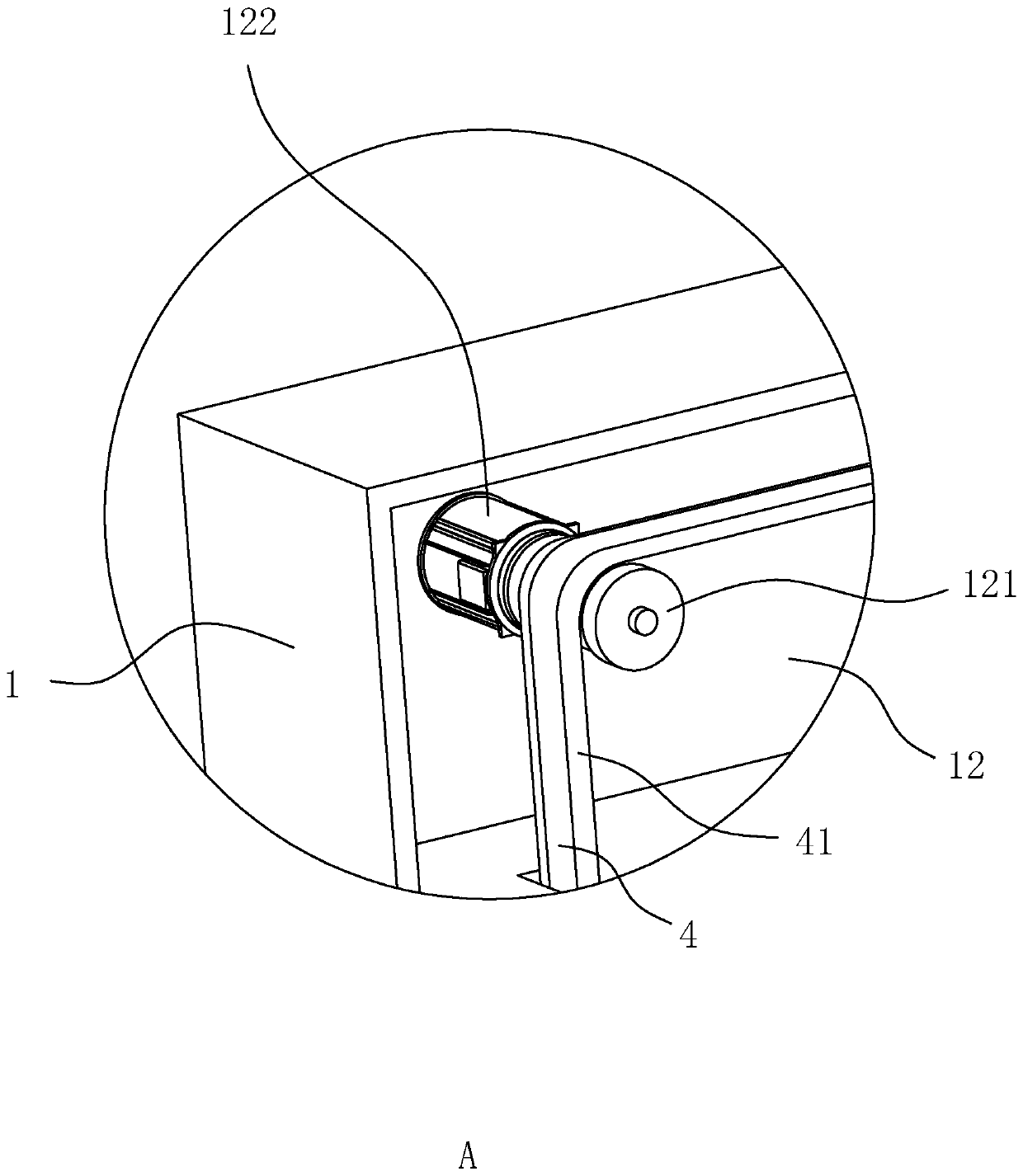

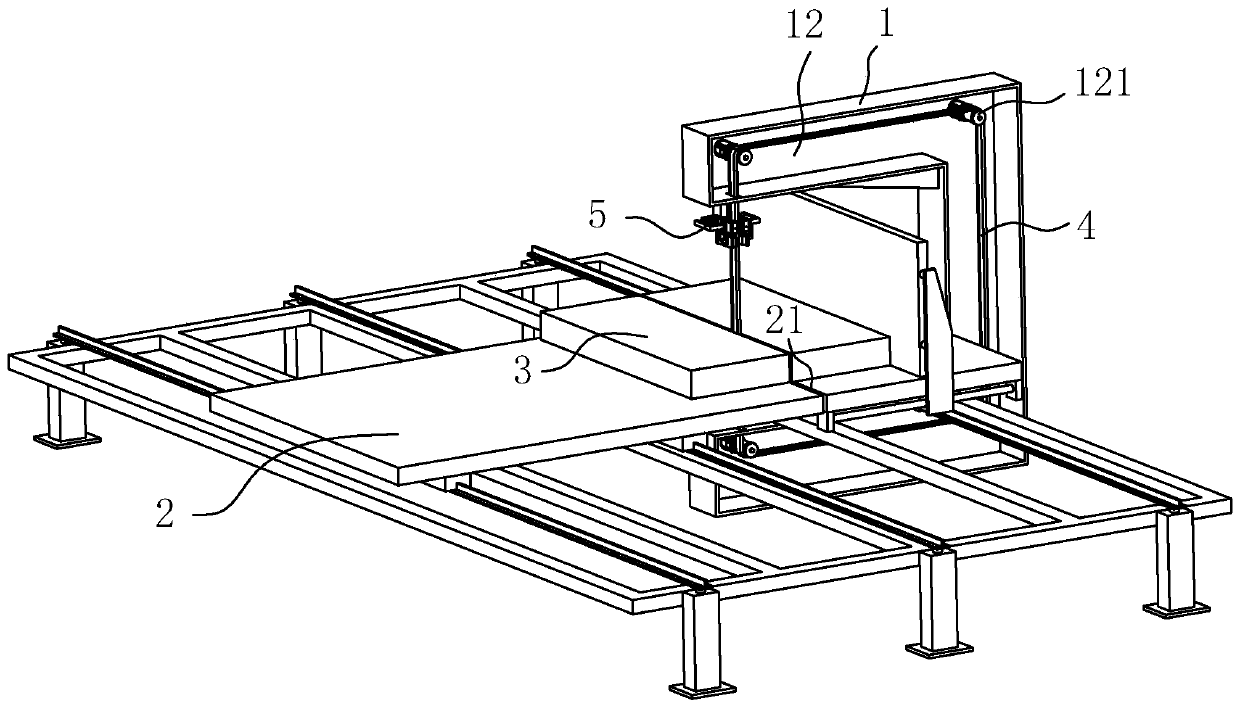

[0037] An automatic rock wool cutting machine, refer to image 3 and Figure 4 , which includes a frame 1, an annular knife belt 4 sleeved on the frame 1 and a drive motor; the inside of the frame 1 is provided with a transmission cavity 12, and the transmission cavity 12 is a "匚"-shaped structure; the transmission cavity Four corners of cavity 12 are all provided with supporting roller 121, to support endless cutter belt 4, driving motor is fixed on the inner sidewall of transmission cavity 12 by screw, and driving motor is as first driving member 123; The rotating shafts are all fixedly connected with the support roller 121 to drive the support roller 121 and the endless knife belt 4 to rotate.

[0038] refer to image 3 , the frame 1 is provided with a workbench 2, the movement of the workbench 2 is controlled by a servo system; the rock wool 3 is placed on the workbench 2; the workbench 2 is provided with a knife gap 21 for the annular knife belt 4 to pass Pass.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com