Low-noise polyurea lubricating grease and preparation method thereof

A polyurea lubricating grease and low-noise technology, which is applied in the field of lubricating grease, can solve the problems of unsatisfactory noise reduction performance of lubricating grease and high noise of low-vibration bearings, and achieve the effect of good vibration value, stable vibration value and reduced noise value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

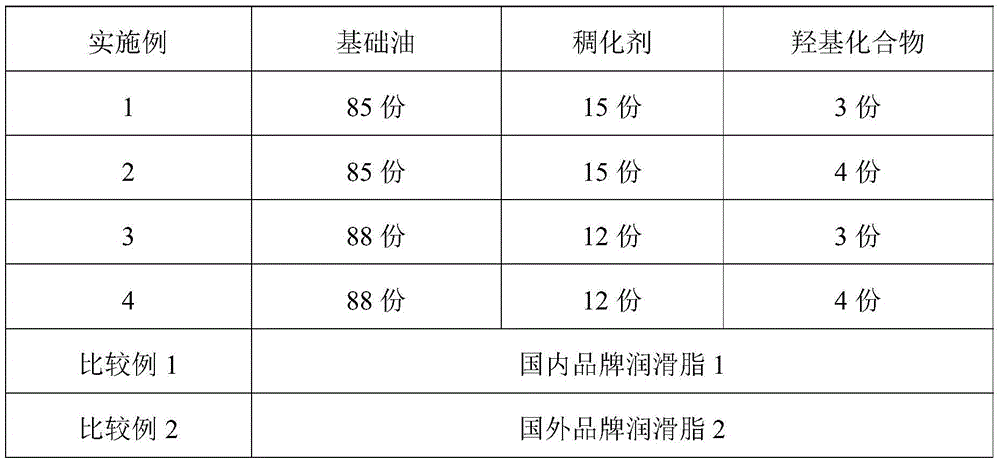

[0022] According to the parts by weight in Table 1, weigh the required amount of base oil and polyurea thickener, heat and stir to 150-175°C, heat at a constant temperature for 120-240 minutes, stop heating and cool at room temperature to 140°C, add the hydroxyl compound, Stir and cool to 60-80°C, filter the grease with a sieve, continue to cool to room temperature, and grind it three times with a three-roller machine to obtain low-noise polyurea grease. The type and amount of each component in the grease are shown in Table 1.

[0023] Table 1

[0024]

Embodiment 5

[0026] [Examples 1-4] were tested for cone penetration and bearing vibration, and the test results are shown in Table 2.

[0027] For two commercially available lubricating greases commonly used in home appliances or office equipment (one domestic brand and one foreign brand): domestic brand grease 1 and foreign brand grease 2, bearing vibration value, cone penetration (GB / T269- 91) test, the test results are shown in Table 2.

[0028] Table 2

[0029] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com