Vertical spiral liquid-solid centrifuge for realizing ultralow water content of solid products

A technology with ultra-low water content and solid products, applied in the field of centrifuges, can solve the problems of high noise, large vibration of centrifuges, low differential transmission ratio, etc., and achieve the effect of improving separation quality and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

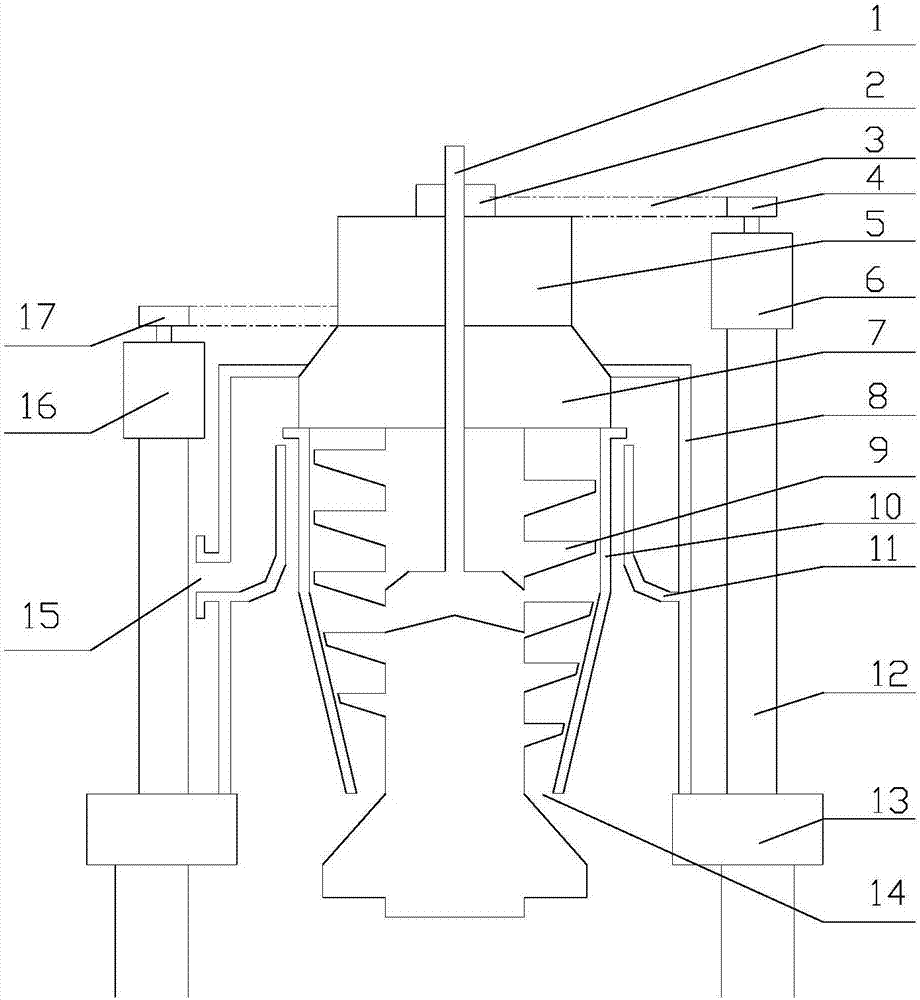

[0024] Such as figure 1 The vertical spiral liquid-solid centrifuge shown is driven by a main motor 16 and an auxiliary motor 6, wherein the main motor 16 drives the drum 10 and the outer ring gear of the multi-stage planetary gear differential; the auxiliary motor 6 drives the multi-stage planetary gear Differential gear input shaft, and then drives screw pusher 9. The main motor 16 and the auxiliary motor 6 are respectively controlled by two frequency converters with stepless speed regulation.

[0025] The driving wheel 17 of the main motor drives the driven wheel of the main motor through a V-belt or a synchronous belt. The driven wheel of the main motor is coaxially connected with the outer ring gear of the multi-stage planetary gear differential. 10 coaxial connections, rotating at the same speed.

[0026] The driving wheel 4 of the auxiliary motor drives the driven wheel 2 of the auxiliary motor through a V-belt or a synchronous belt, and the driven wheel 2 of the aux...

Embodiment 2

[0038] The basic structure of the vertical spiral liquid-solid centrifuge in the present embodiment is the same as in Example 1, and the specific parameters of the centrifuge are as follows:

[0039] 1. The driving wheel and the driven wheel of the motor are connected by a V-belt and a V-belt pulley;

[0040] 2. The multi-stage planetary gear differential adopts a 4-stage planetary gear set with a transmission ratio of 1:256;

[0041] 3. The cone angle of the drum cone section is 4°, and the cone angle of the screw pusher is 4°;

[0042] 4. The length ratio of the drum column section to the cone section is 1.5:1, and the length ratio of the screw propeller column section to the cone section is 1.5:1;

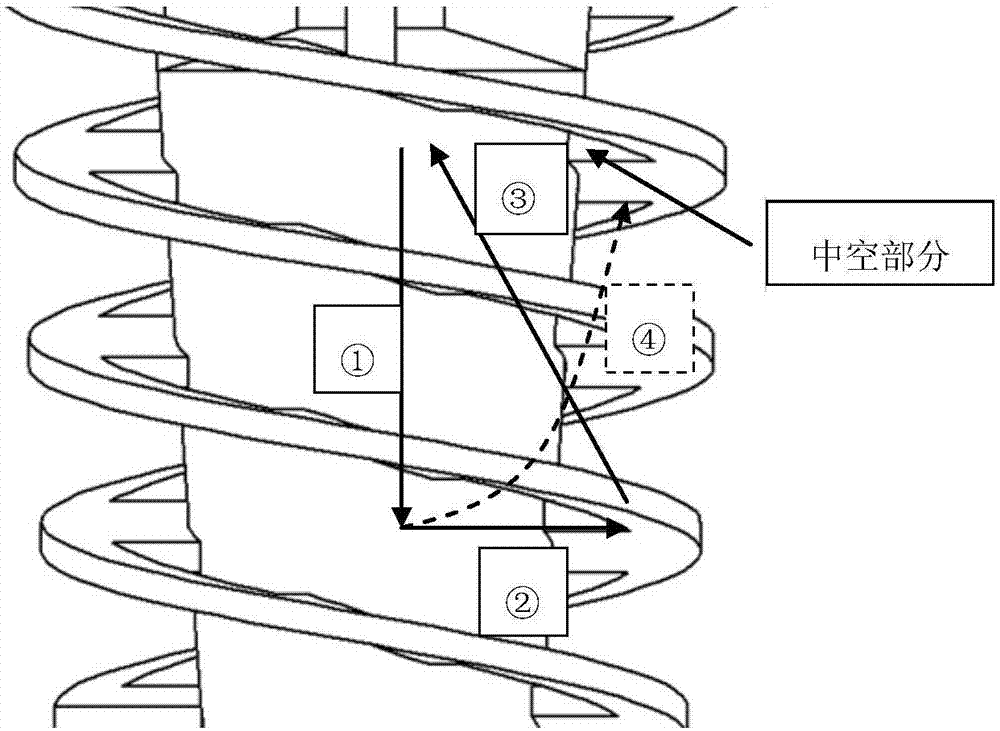

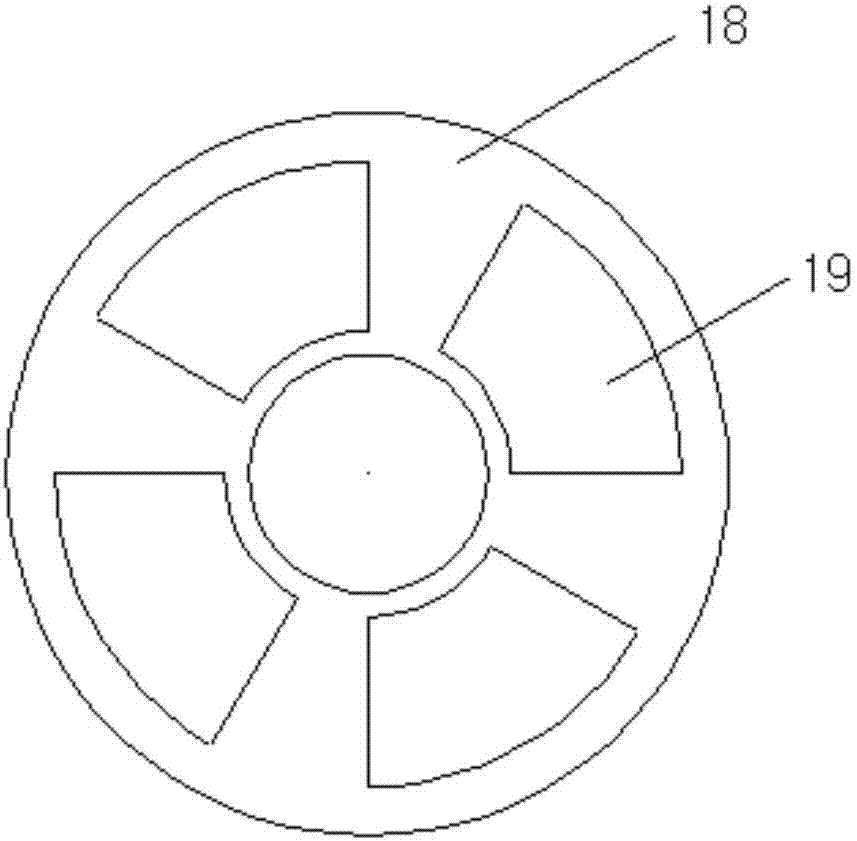

[0043] 5. The total area of openings on the spiral blade accounts for 1 / 3 of the total area of the entire spiral blade;

[0044] 6. The distance between the helical blade of the screw propeller and the inner wall of the drum is 1mm.

[0045] Operating parameter settings: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com