Plastic wiper convenient for cleaning automobile glass

A technology of automotive glass and plastic, applied to plastic wipers. It can solve the problems of time-consuming assembly, low production cost, and low productivity, and achieve the effects of reducing wind resistance, facilitating installation, and increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

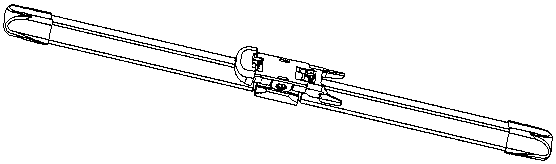

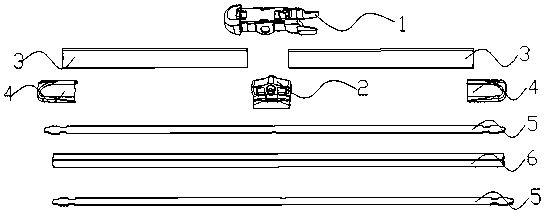

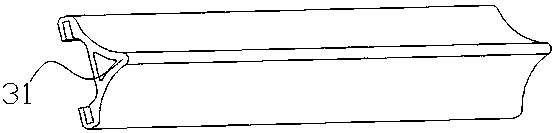

[0014] refer to figure 1 , figure 2 and image 3 Among them, the present invention includes an accessory (1), a bracket (2), two deflectors (3), two buckles (4), two shrapnels (5), a brush (6), guide Flow sheet spine (31) is in the middle, can brush water better when brushing test.

[0015] refer to Figure 4 , Figure 5 and Figure 6 Among them, the attachment (1) of the present invention is different from the traditional attachment. There is a square hole I (11) on one end of the attachment (1), and a square hole on the other end, and there is a boss I (12) in the hole. There is a guiding slope I (13) on the boss I (12). A hole wall (14) is respectively arranged on the side of the accessory (1), and a circular hole (15) is arranged on the hole wall (14). The hole wall (14) is very thin, and the inside of the accessory (1) is a cavity structure. There is respectively a boss II (16) on the side of the accessory (1), and there is a guiding slope II (17) on the boss II (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com