Durable gear-shaped hydraulic coupling

A hydraulic coupling and tooth type technology, which is applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of reducing maintenance costs, tooth end jamming, jamming, etc., to prolong the service life, The effect of increasing the coaxiality error and improving the ability to transmit torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

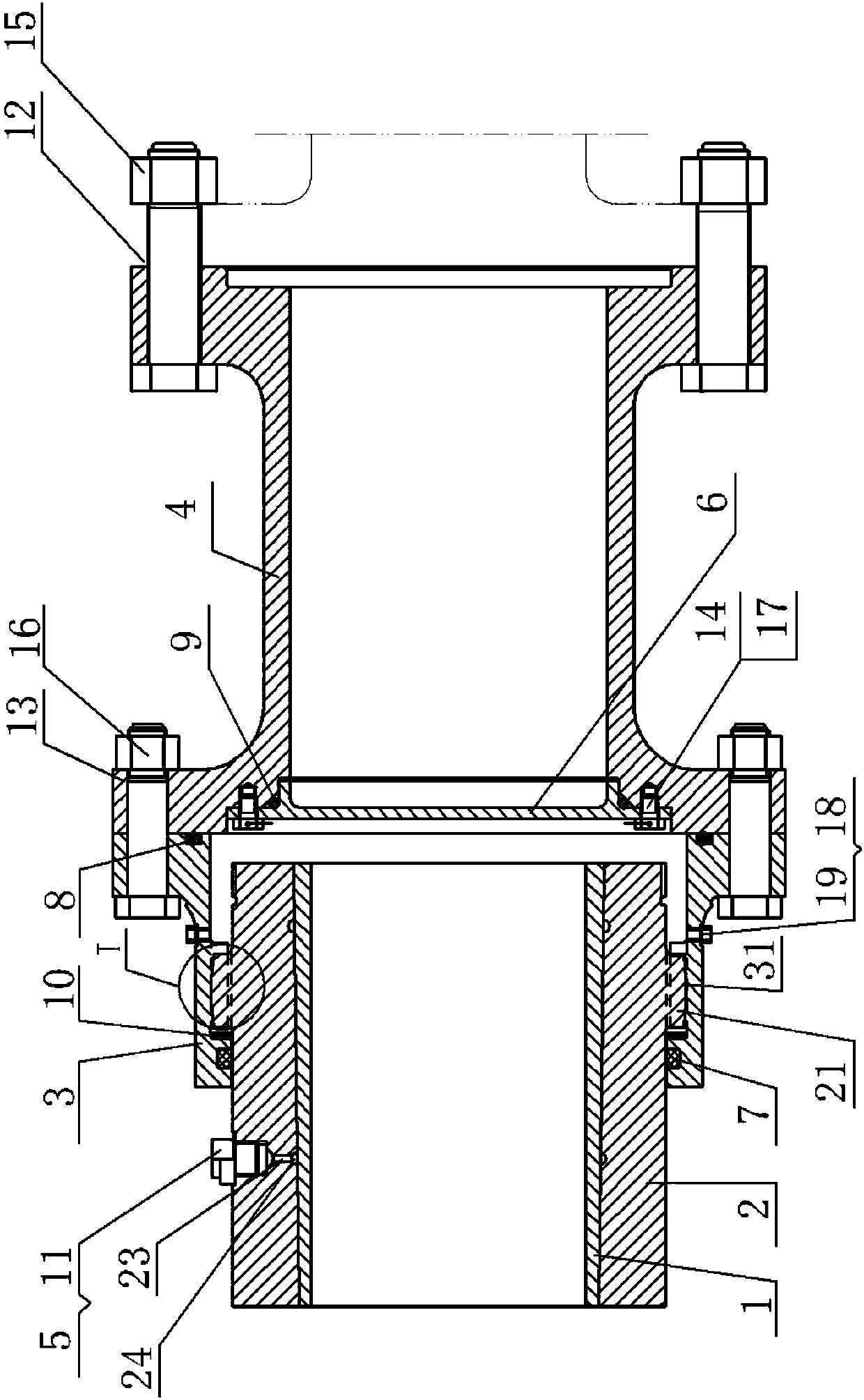

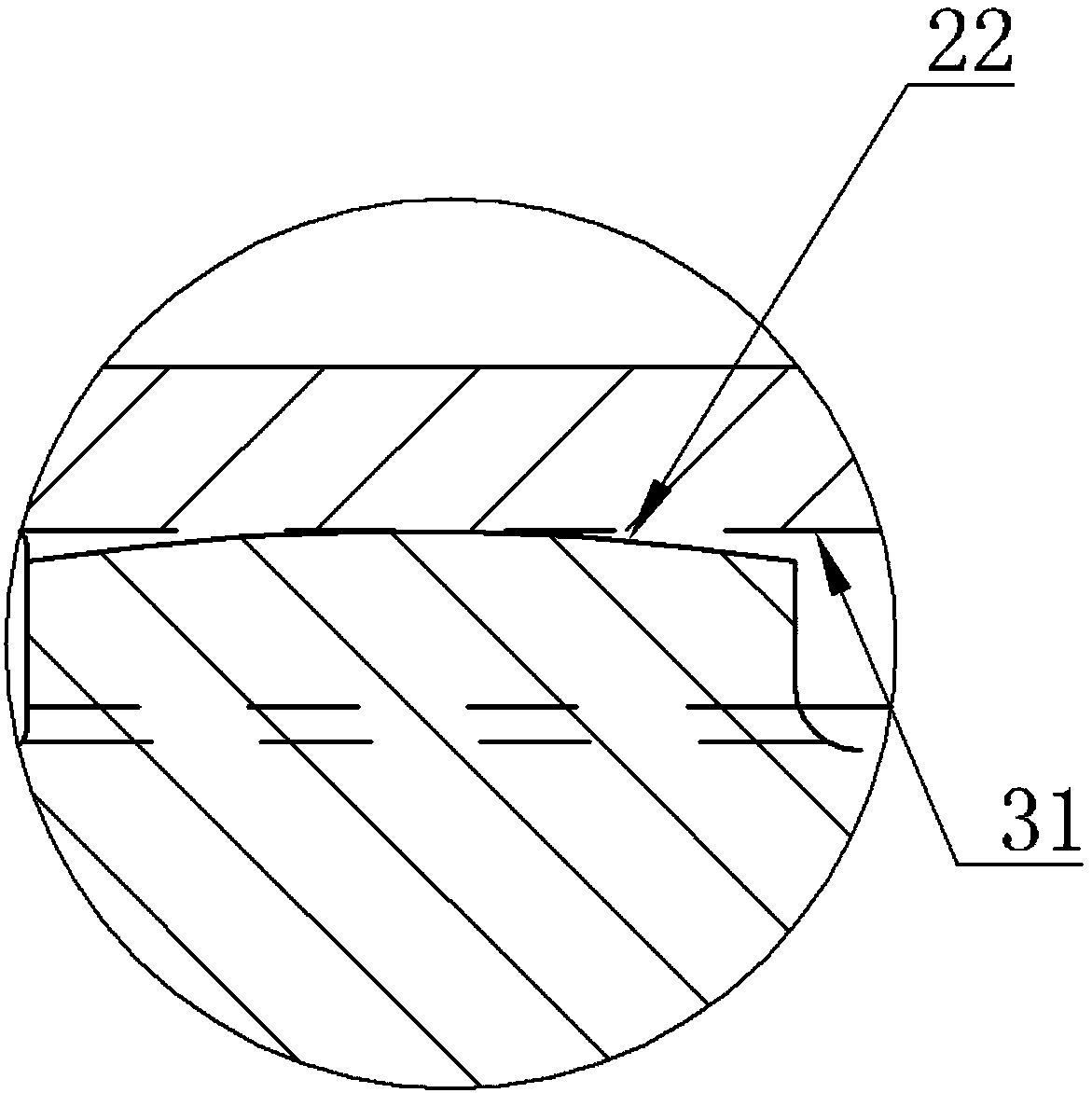

[0014] See figure 1 with figure 2 , a durable toothed hydraulic coupling of the present invention, which includes an inner sleeve 1, an outer sleeve 2, a flange sleeve 3 and an assembly and disassembly flange 4, the outer sleeve 2 is tightly pressed on the outer circumference of the inner sleeve 1 and the inner circumference of the outer sleeve 2 surface and the outer peripheral surface of the inner sleeve 1 are in a taper fit, the inner hole of the inner sleeve 1 is an equal-diameter circular hole, and the outer circumference of the outer sleeve 2 is provided with outer teeth, and the outer teeth are straight arc teeth 21 whose tooth surface 22 is spherical and the center of the spherical surface is On the gear axis, and the top of the straight arc tooth 21 and the two tooth sides are made into arc chamfers, the inner circumference of the flange sleeve 3 is provided with an inner straight tooth 31, and the flange sleeve 3 is sleeved on the outer circumference of the outer sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com