Steel plate tailoring blanking die and wedge guide device

A blanking die and guide device technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large limitations in the use of rollers, affecting the blanking accuracy, cutting tools damaging the mold, etc., so as to reduce the number of defective products. The effect of output, improving guidance efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

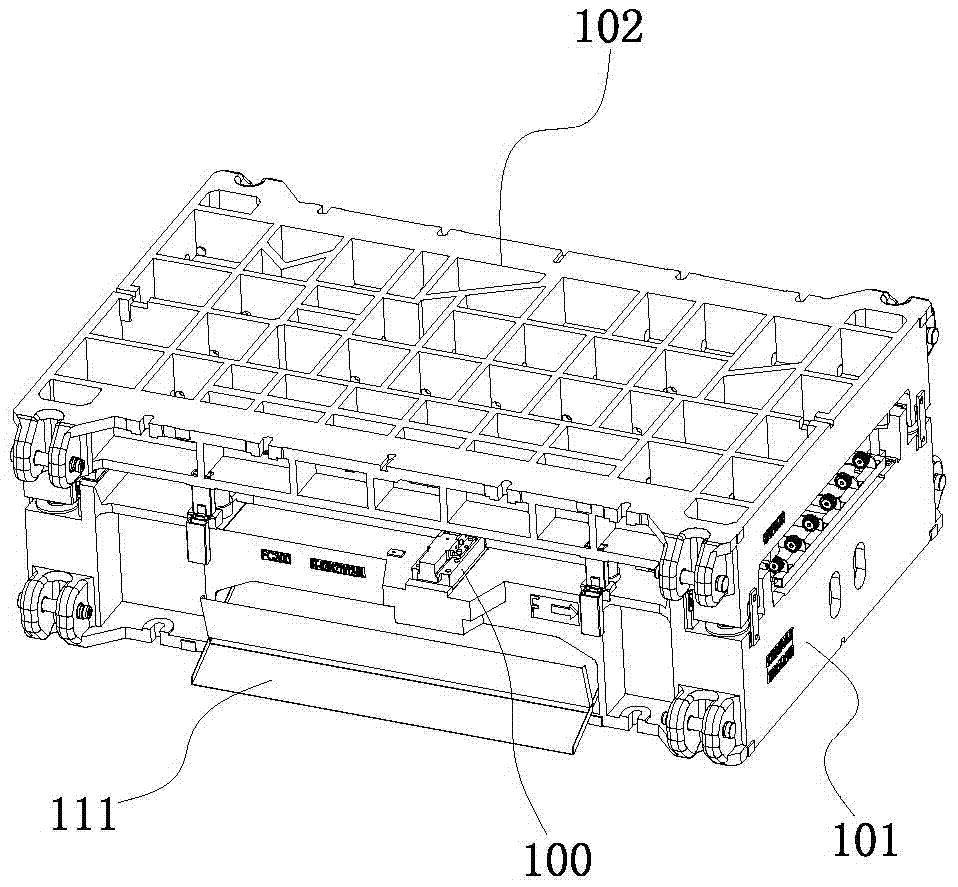

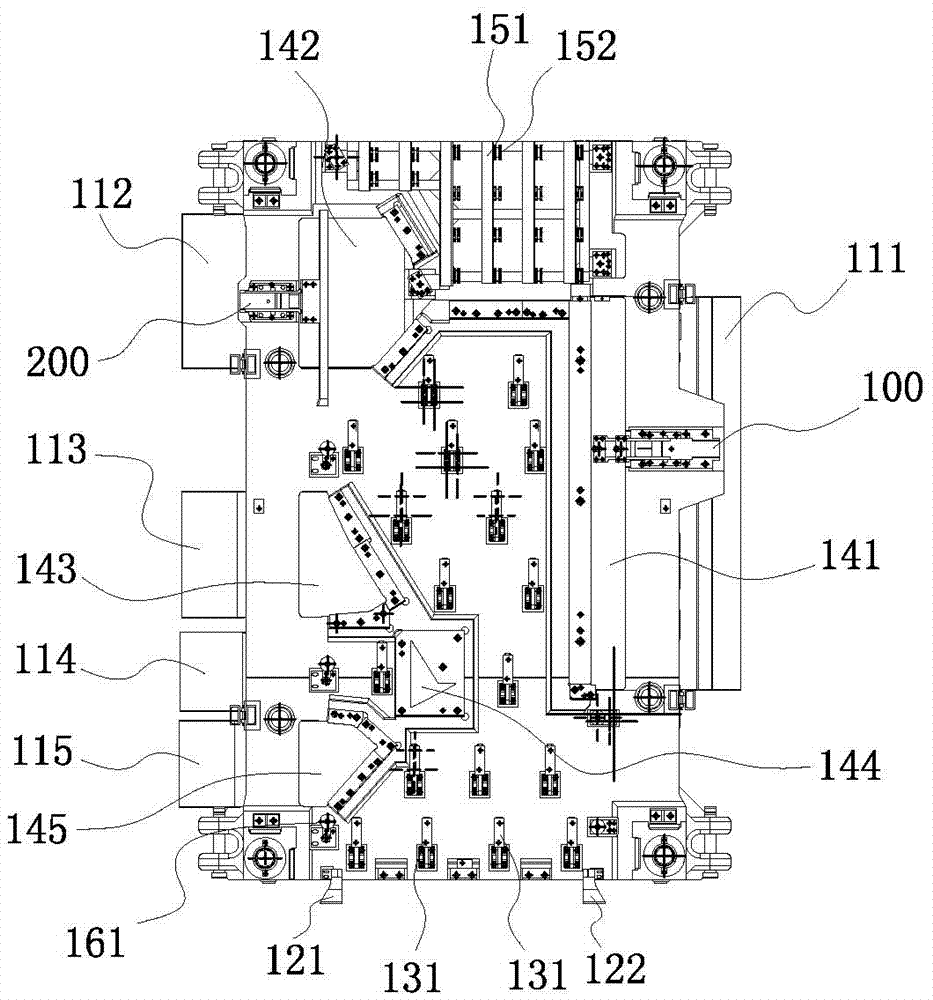

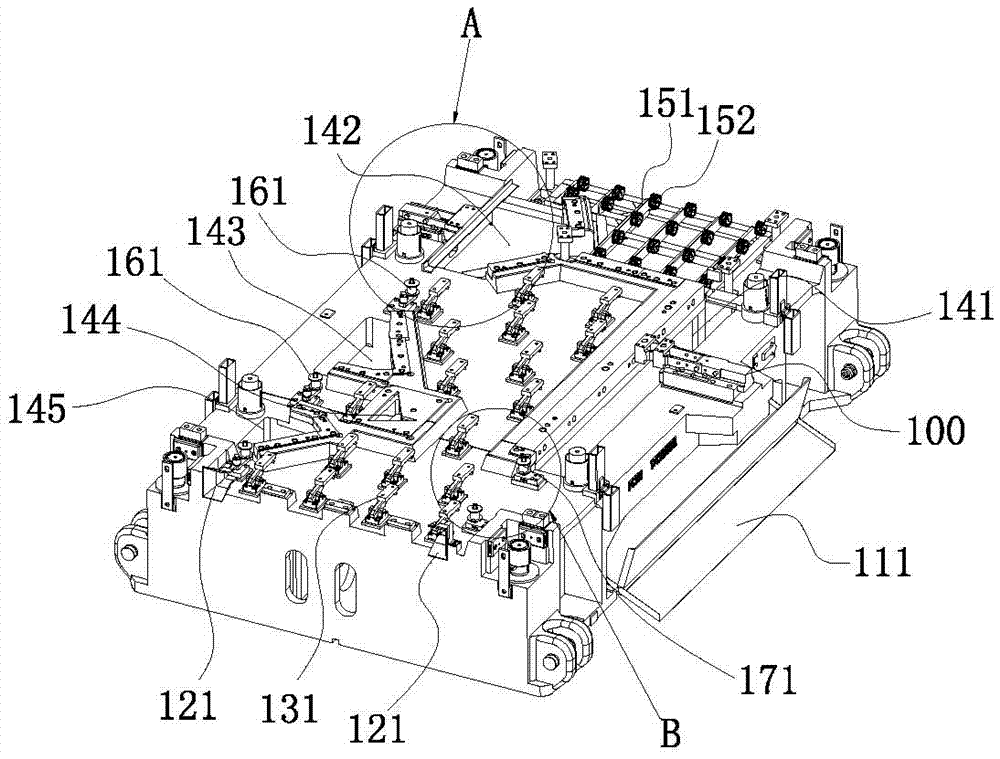

[0027] Such as Figure 1 to Figure 5 As shown, the steel plate cutting blanking mold includes an upper template 102 and a lower template 101, and a plurality of outlets are provided on both sides of the lower template 101, and a drop that communicates with the outlet is provided on the top surface of the lower template 101. The upper template 101 is provided with a finishing tool for cutting (not shown in the figure), and the lower template 101 is provided with a conveying device, a supporting device, a first guiding device, a second guiding device and a third guiding device device, the conveying device is arranged at the exit of the lower formwork 101, and the conveying device includes a plurality of rail rods 151, and the rail rods 151 are provided with a number of support wheels 152 for supporting steel plates; the function of the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com