A metal heat dissipation module and its preparation method

A heat dissipation module and metal technology, which is applied in the field of electronic component preparation, can solve problems such as noise, large volume, and easy precipitation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

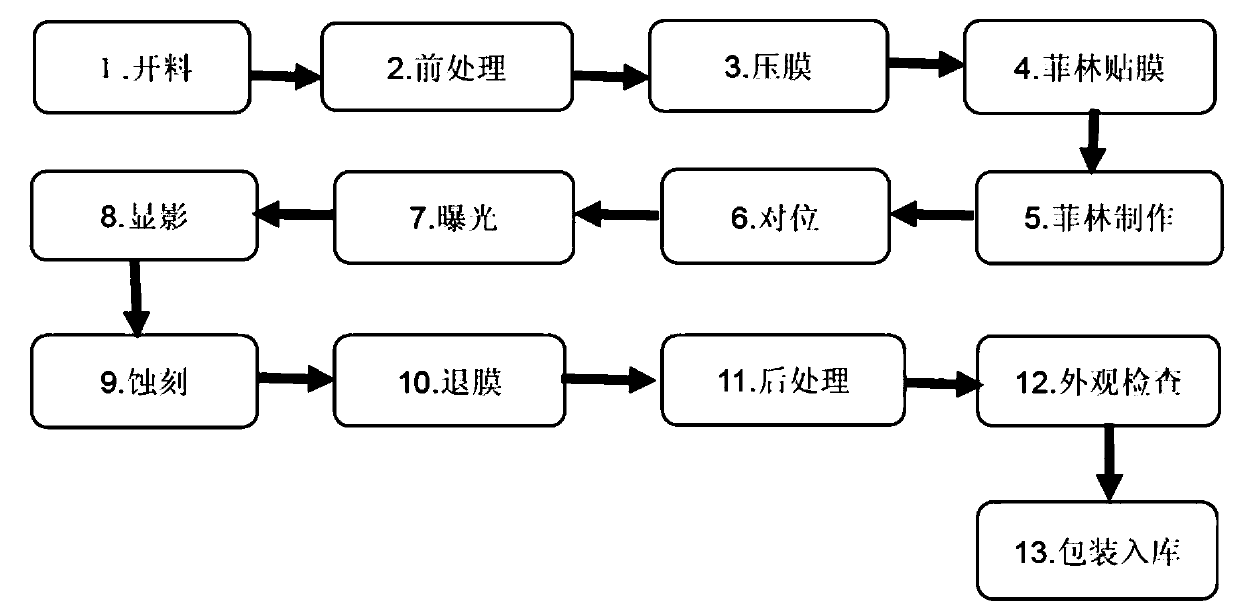

[0055] This embodiment provides a method for preparing a metal heat dissipation module, which uses an etching method to prepare a metal heat dissipation module, which includes the following steps:

[0056] (1) Pre-treatment: pre-treatment sandblasting of VC copper plate;

[0057] (2) Lamination: Carry out lamination treatment on the pre-treated VC copper plate, adopt wet lamination, the temperature of lamination treatment is 110°C, and the pressure is 4kg / cm 2 , the speed is 35Hz;

[0058] (3) Film sticking film: Use a laminating machine to carry out film sticking treatment on the film. The speed of the laminating machine is 2000mm / min, and the pressure is 4kg / cm 2 Before pasting, use film water to clean the film surface of the film;

[0059] (4) Film production: scribing film: take two pieces of film, denoted as L1 and L2, cut and tear off the film at the end of the non-directional hole along the white line on the film; paste double-sided tape: take the middle of film L1 an...

Embodiment 2

[0066] This embodiment provides a method for preparing a metal heat dissipation module, which uses an etching method to prepare a metal heat dissipation module, which includes the following steps:

[0067] (1) Pre-treatment: pre-treatment sandblasting of VC copper plate;

[0068] (2) Lamination: Carry out lamination treatment on the pre-treated VC copper plate, using wet lamination, the temperature of lamination treatment is 110±10°C, and the pressure is 3-5kg / cm 2 , the speed is 30-35Hz;

[0069] (3) Film sticking film: Use a laminating machine to carry out film sticking treatment on the film. The speed of the laminating machine is 2000mm / min, and the pressure is 3-5kg / cm 2 ; Before pasting, use film water to clean the film surface of the film;

[0070] (4) Film production: scribing film: take two pieces of film, denoted as L1 and L2, cut and tear off the film at the end of the non-directional hole along the white line on the film; paste double-sided tape: take the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com