Structural design of reflective polarization conversion orbital angular momentum convergence metasurface

An orbital angular momentum and polarization conversion technology, which is applied to electrical components, antennas, etc., can solve the problems of effective transmission and reception of unfavorable information, lack of reflective metasurfaces, etc., and achieves the effects of simple structure, low cost, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

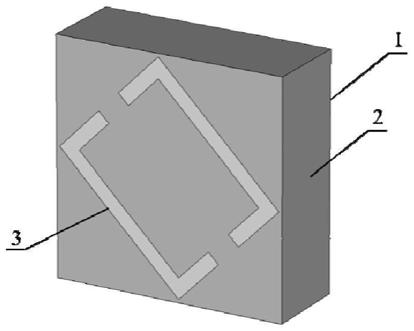

[0030] In this embodiment: n=8, the length and width of the bottom metal layer and the middle dielectric layer are both 10 mm, and the thickness of the middle dielectric layer is 3 mm; both the bottom metal layer and the top metal pattern layer have an electrical conductivity of 5.8×10 7 S / m metal copper; the intermediate dielectric layer is made of Teflon with a dielectric constant of 2.65 and a loss of 0.0002.

[0031] Specific steps are as follows:

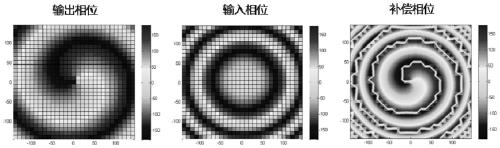

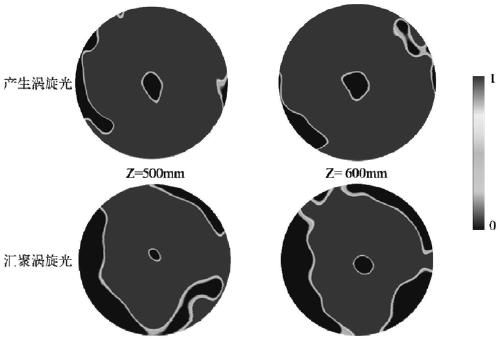

[0032] Step 1: Design an initial basic unit structure with polarization characteristics according to the basic principle of polarization conversion, as shown in Figure 1. In CST, the polarization unit structure is modeled, simulated and optimized. The basic unit structure includes a bottom metal layer 1, a middle dielectric layer 2, and a top metal pattern layer 3, wherein the bottom metal layer 1 and the middle dielectric layer 2 have the same periodic size, and the center of the pattern layer 3 is symmetrically opened to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com