Upper tray device for fluid polishing machine

A fluid polishing and disc-carrying technology, used in grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as low yield, difficulty in reaching expected values, uneven polishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

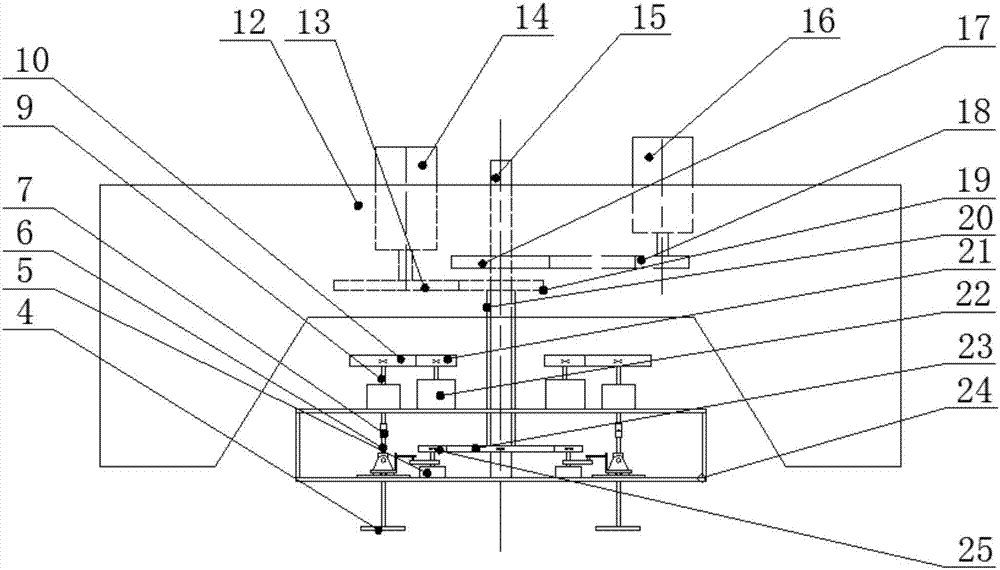

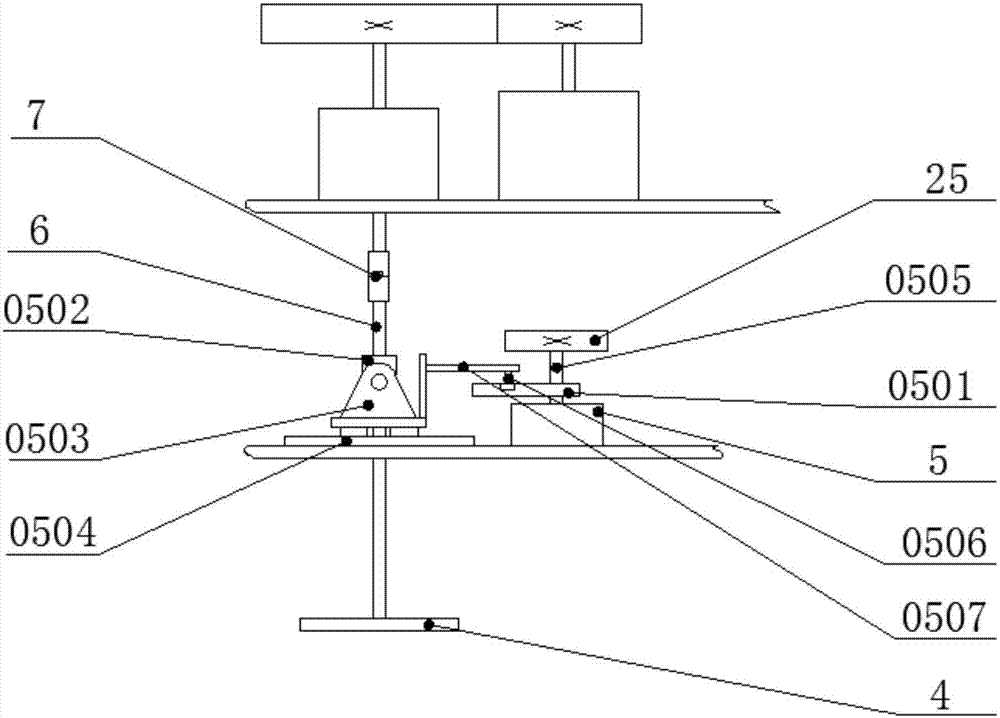

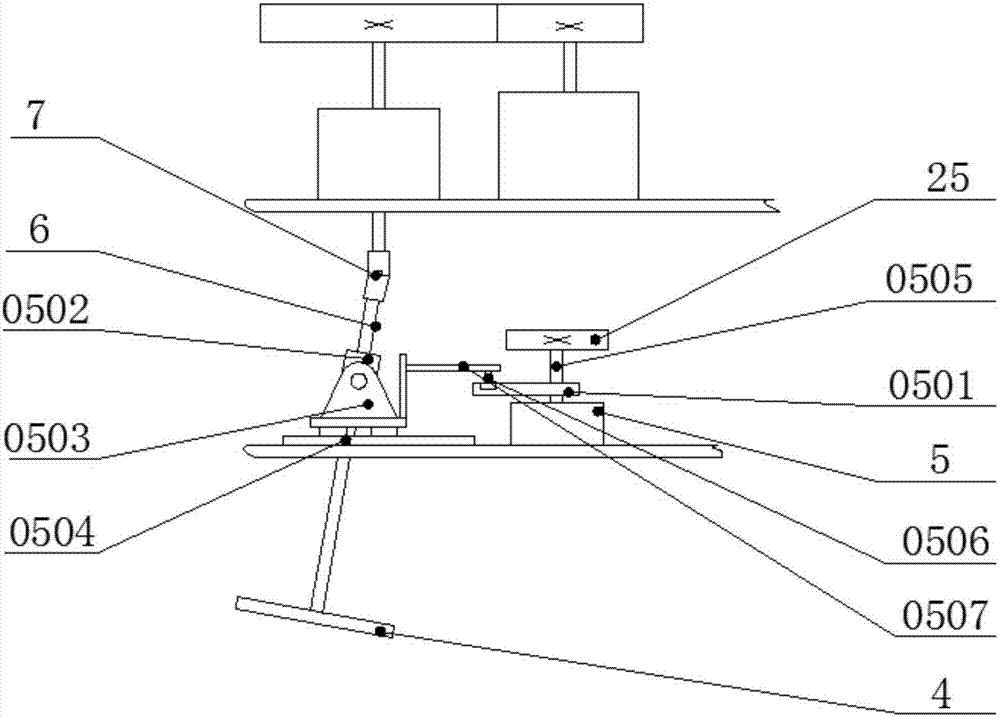

[0019] With reference to the accompanying drawings, this embodiment includes an upper plate beam 12, a revolution mechanism, a carrier plate swing mechanism and a carrier plate rotation mechanism. The revolution mechanism, the carrier plate swing mechanism and the carrier plate rotation mechanism are installed on the upper plate beam 12. The revolution mechanism includes an upper disk revolution main shaft 15, an upper disk revolution drive motor 16, a revolution transmission pulley 17, an upper disk revolution drive pulley 18 and an upper disk 24, and the upper disk revolution drive pulley 18 is installed on the upper disk revolution drive motor 16 Above, the revolution transmission pulley 17 is installed on the upper disk revolution spindle 15, the upper disk revolution drive pulley 18 is connected with the revolution transmission pulley 17 through a belt, and the upper disk 24 is connected with the upper disk revolution spindle 15; The carrier swing mechanism includes a swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com