A sporting goods skin die-cutting machine

A sporting goods, die-cutting machine technology, applied in the direction of metal processing, etc., can solve the problem of easy cutting of materials, not easy to take out, etc., to achieve the effect of preventing material falling off, increasing stability, and preventing direction deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

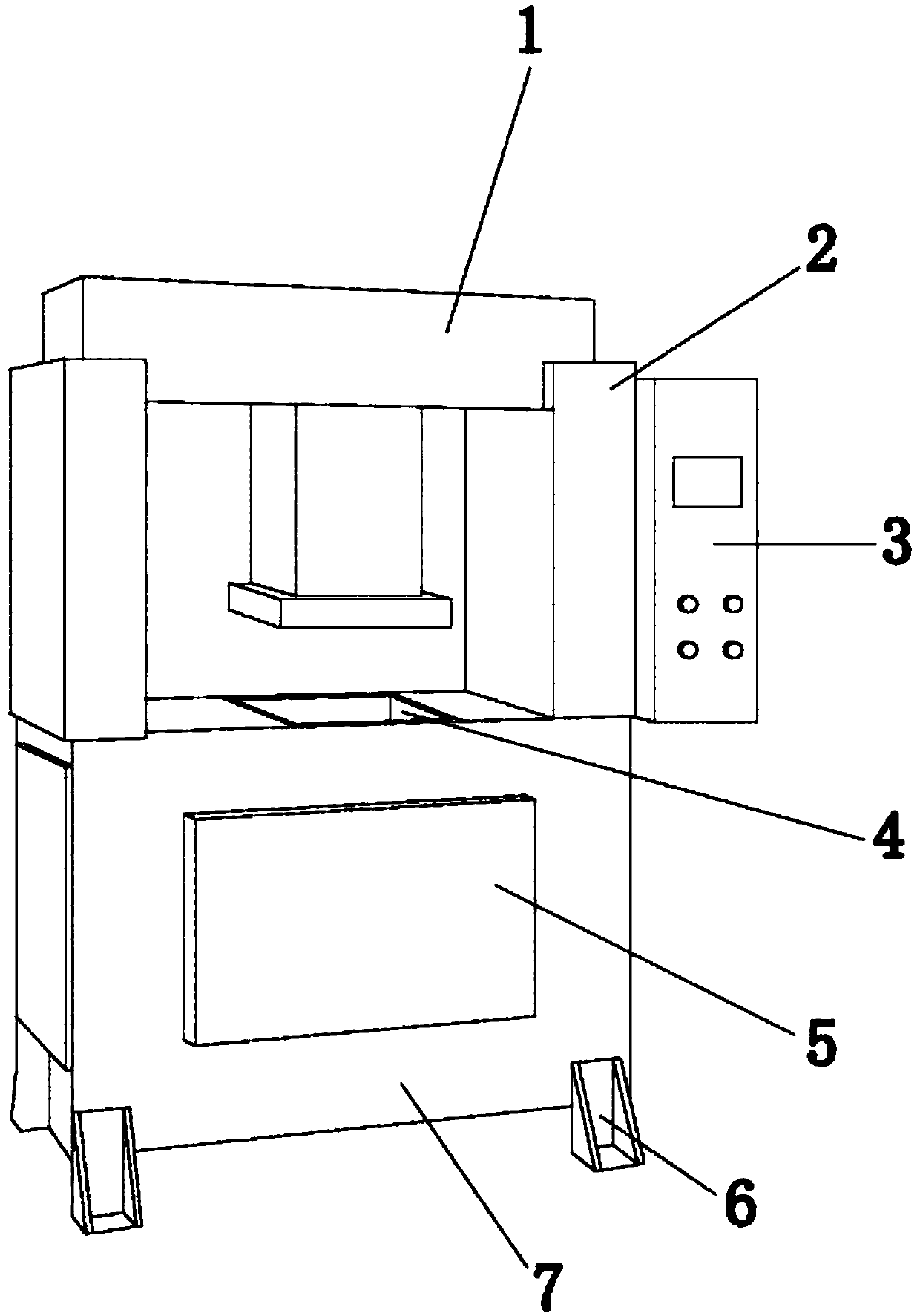

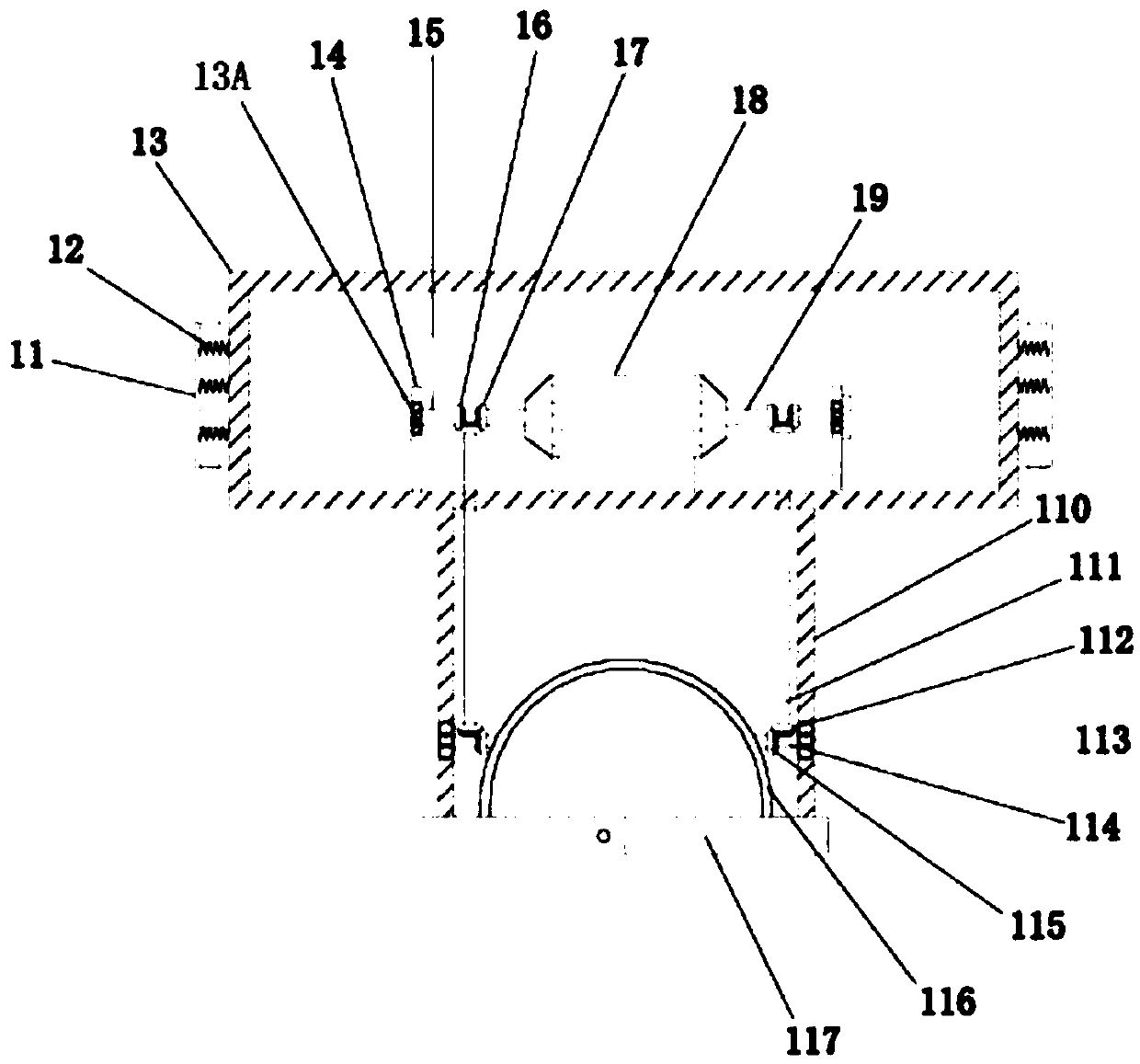

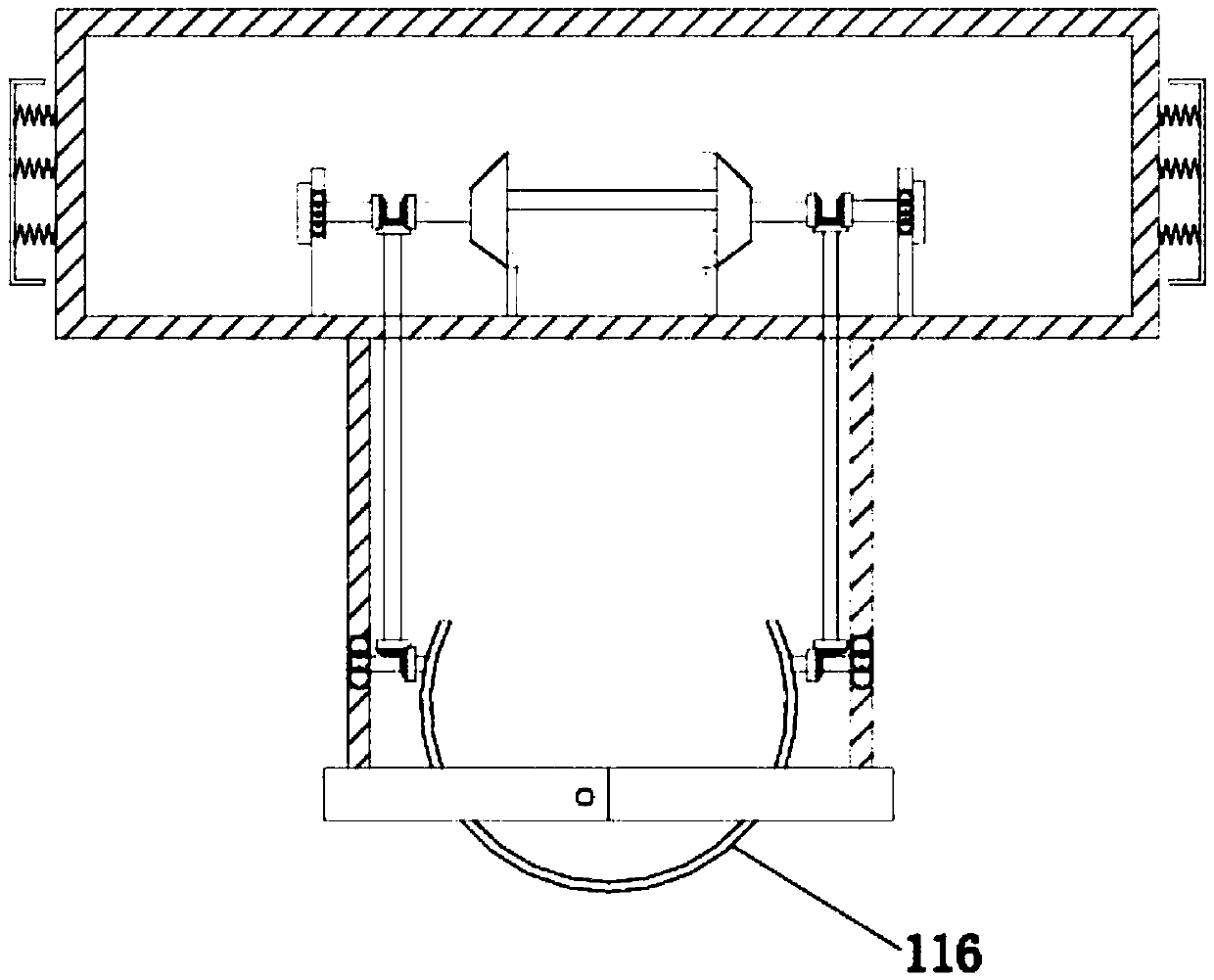

[0025] see Figure 1-Figure 4, the present invention provides a sporting goods skin die-cutting machine, the structure of which comprises a die-cutting machine 1, a fixed pillar 2, a controller 3, a waste material inlet 4, a cleaning door cabinet 5, a bottom support leg 6, and a waste material collection box 7; The central position of the front end of the waste collection box 7 is provided with a cleaning door cabinet 5, the cleaning door cabinet 5 and the waste collection box 7 are hingedly connected, and the bottom of the waste collection box 7 is evenly and equidistantly provided with four bottom support legs 6. The bottom supporting feet 6 and the waste collection box 7 are welded together, and the top center of the waste collection box 7 is provided with a waste introduction port 4, and the waste introduction port 4 and the waste collection box 7 are integrated structures A die-cutting machine 1 is arranged above the waste collection box 7, and fixed pillars 2 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com