Non-woven fabric roll packing box capable of being directly stacked

A technology of non-woven fabrics and packaging boxes, which is applied in the field of non-woven fabric roll packaging boxes, which can solve the problems that multiple packaging boxes cannot be stacked, the extrusion of round paper tube non-woven fabric rolls, and occupying a large area of the site, etc., to achieve improved Packing efficiency, short overall length, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

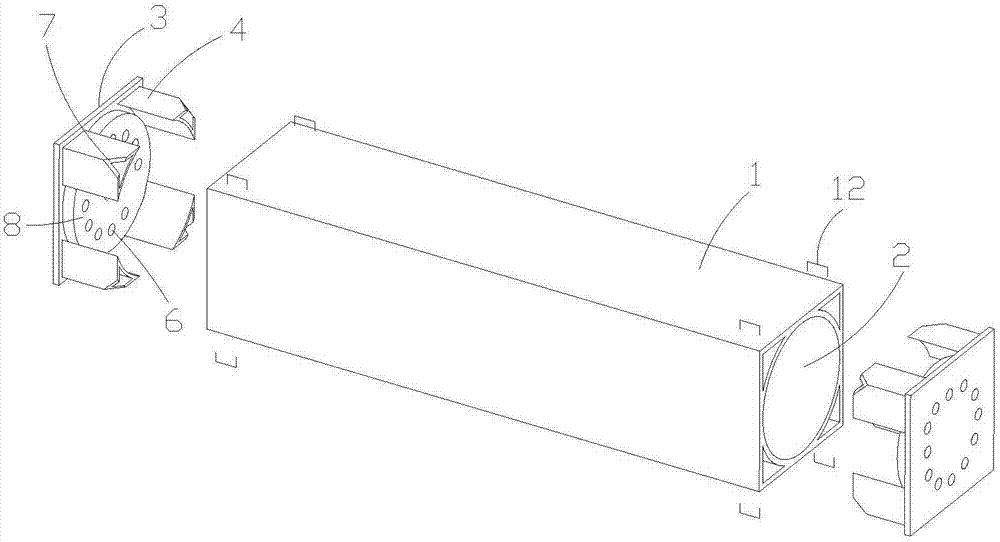

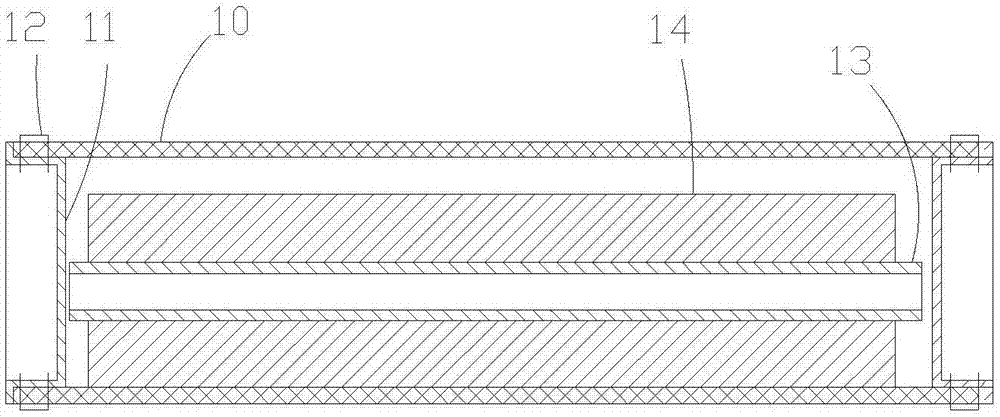

[0018] Example. A non-woven roll packaging box that can be stacked directly, such as figure 1 As shown, it includes a paper tube and end caps located at both ends of the paper tube; the paper tube includes a square tube 1 and a round tube 2 inside the square tube 1, and the square tube 1 is bonded to the round tube 2; the end cap includes The square cover plate 3 is provided with pins 4 at the four corners of the cover plate 3 facing the paper tube. Both the square tube 1 and the round tube 2 are made of cardboard.

[0019] The cover plate 3 is provided with ventilation holes 6 .

[0020] The pin 4 is provided with a guiding slope 7 .

[0021] A protrusion 8 is provided on the side of the cover plate 3 facing the paper tube, and the protrusion 8 is embedded in the round tube 2, and the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com