Girder track manufacturing process

A manufacturing process and girder technology, which is applied in the field of girder manufacturing, can solve problems such as poor work efficiency, out-of-tolerance side bending, and excessive camber of the girder structure, and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

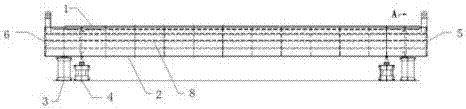

[0016] A girder track manufacturing process, the girder 2 includes a main girder, a box body 8 is arranged in the main girder, and a partition is arranged in the box body 8, comprising the following steps:

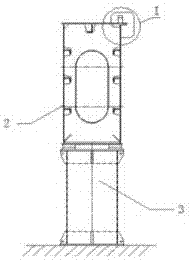

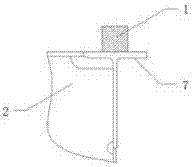

[0017] (1) Position and fix the square steel track 1 on the upper panel of the girder 2, specifically including the following steps: s1, arrange the tire frame 3 and the jack 4 under the girder 2, release the stress of the girder 2 in a free state, and place the girder 2. The zero points of the flexible leg side 5 and the rigid leg side 6 are lifted to the same horizontal point; s2, check the flatness of the square steel track 1 and the rail bearing beam 7 fixed on the side of the girder 2; if the square steel tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com