A kind of ink-jet printing ink of mixed solvent and preparation method thereof

A technology of inkjet printing and mixed solvents, applied in ink, household utensils, applications, etc., can solve the problems of difficult to guarantee uniformity, large restrictions, complicated process, etc., achieve excellent uniformity and improve the effect of inkjet state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add polyacrylamide (weight-average molecular weight: 40,000) to ethylene glycol, stir at 45°C for more than 3 hours to fully dissolve, then add ethylene glycol methyl ether equal to the volume of ethylene glycol, and stir until the solution is clear, where The amount of polyacrylamide added is 1% of the total mass of ethylene glycol and ethylene glycol methyl ether; finally, zirconium oxychloride octahydrate with a molar concentration of 0.5M is added, magnetically stirred to dissolve it, and the mixture is obtained after aging for 24 hours. Solvent based inkjet printing inks.

[0024] In addition, an inkjet printing ink using pure ethylene glycol as a solvent was prepared as a control. The type, mass fraction and concentration of zirconium oxychloride octahydrate in the control group were the same as those of the inkjet printing ink of the above-mentioned mixed solvent.

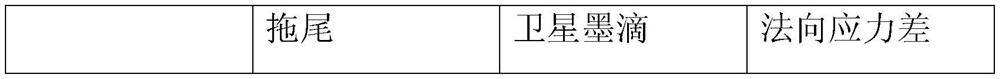

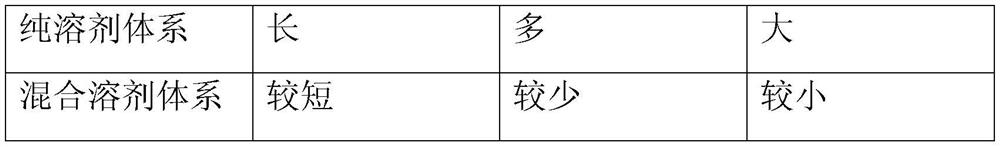

[0025] Observation and comparison of inkjet state of gained inkjet printing ink:

[0026] Fill t...

Embodiment 2

[0031] Add polyvinyl alcohol (weight average molecular weight: 40,000) into deionized water, stir at 45°C for more than 3 hours to fully dissolve, then add ethylene glycol equal in volume to deionized water, and stir until the solution is clear, in which polyvinyl alcohol The addition amount of ethylene glycol is 1% of the total mass of water and ethylene glycol; finally, zirconium oxychloride octahydrate with a molar concentration of 0.5M is added, magnetically stirred to dissolve it, and the inkjet printing ink of the mixed solvent is obtained after aging for 24 hours .

[0032] In addition, an inkjet printing ink with pure deionized water as solvent was prepared as a control. The type, mass fraction and concentration of zirconium oxychloride octahydrate in the control group were the same as those of the inkjet printing ink of the above-mentioned mixed solvent.

[0033] Observation and comparison of inkjet state of gained inkjet printing ink:

[0034] Fill the prepared ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com