Dry land skiing floor tile and manufacturing method

A manufacturing method and a technology of floor tiles, which are applied to pavements, pavement details, roads, etc., can solve the problems of overheating and deformation of the top of plastic raised columns, increased sliding friction, and easy damage of ski floor tiles, and achieve good impact resistance and reduce Frictional resistance, the effect of ensuring convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

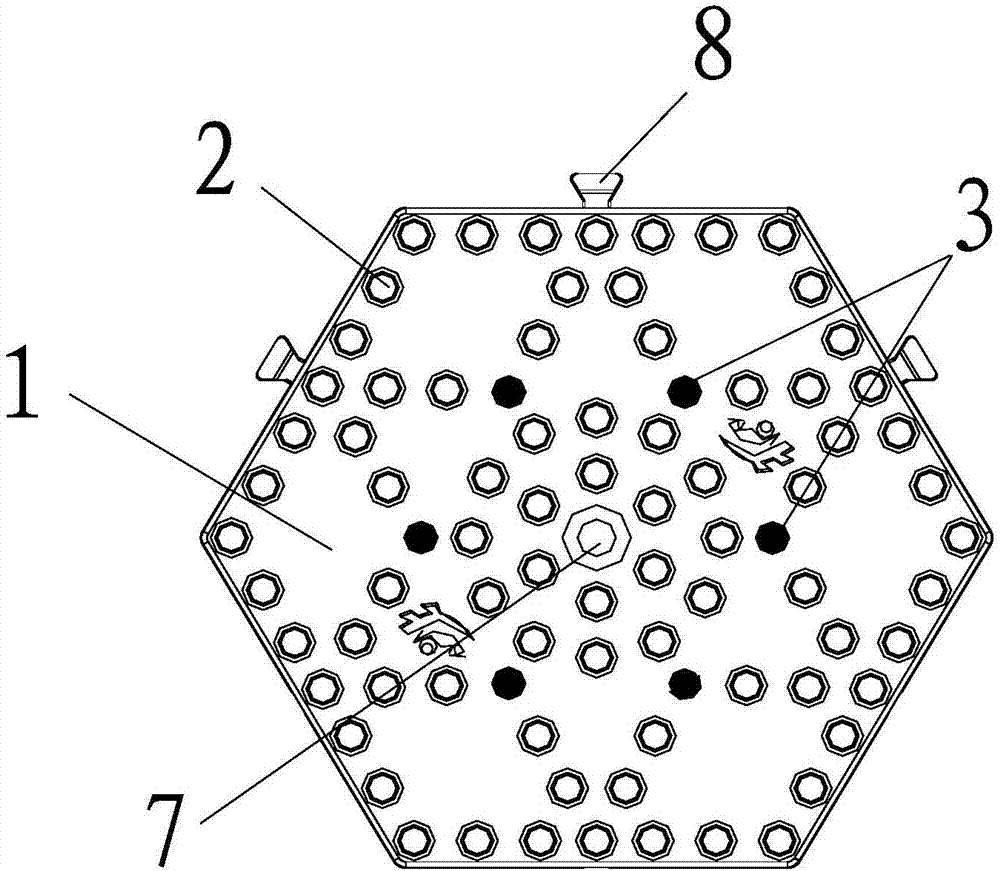

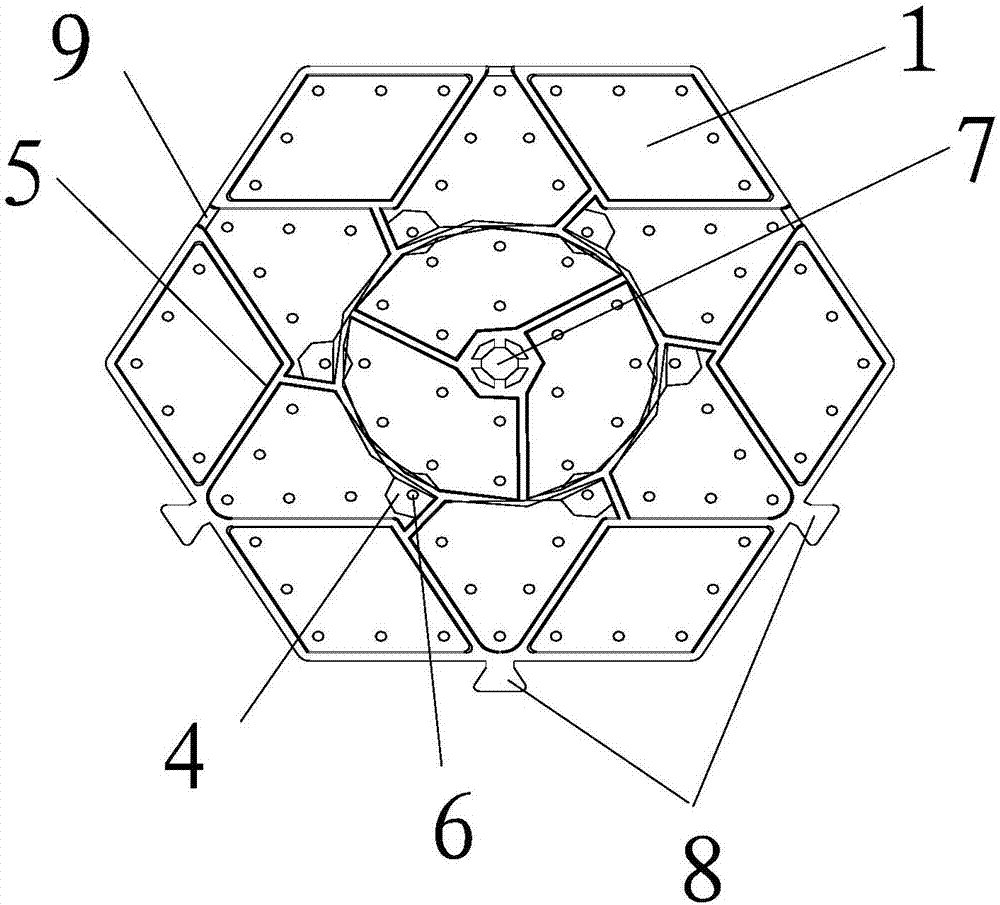

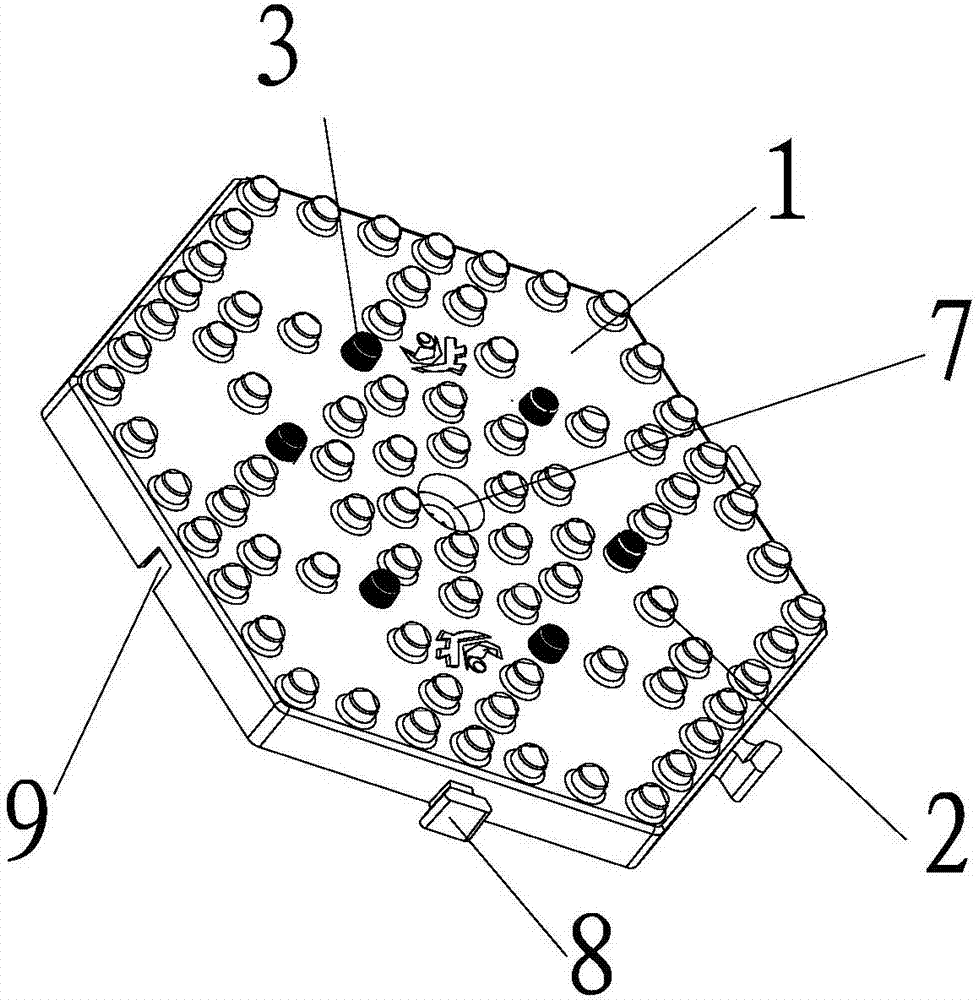

[0043] see Figure 1-Figure 9 , a dryland ski floor tile, comprising a ski floor tile body 1, a round head column 2 is arranged on the upper surface of the ski floor tile body 1, and the number of the round head column 2 is multiple, and a plurality of round head columns 2 are fixed with metal The sleeve 3; or the metal sleeve 3 is fixed on part of the round head column 2 and the number of the metal sleeve 3 is at least three. It can also be 6, 9 or 12 etc.

[0044] The top of the metal sleeve 3 is a curved surface with a smooth surface, the bottom of the metal sleeve 3 is provided with a flange 31, and a gap is opened on the flange 31; the flange 31 is embedded in the ski floor tile body 1. The material of the metal sleeve 3 is 304 stainless steel; the material of the ski floor tile body 1 is plastic. When injection molding dryland ski floor ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com