Dry land skiing floor brick and manufacture method

A technology for floor tiles and dry land, applied in the field of outdoor sports facilities, can solve the problems of overheating deformation of the top of plastic raised columns, increased sliding friction, easy damage of ski floor tiles, etc., and achieves good impact resistance, improved friction resistance, Good anti-shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

[0034] For reasons of convenience only, in the following description, specific directional terms, such as "up", "down", "left", "right", etc., are used with reference to the corresponding drawings and It should not be regarded as a limitation on the present invention, and when the defined direction of the drawings changes, the directions indicated by these words should be interpreted as correspondingly different directions.

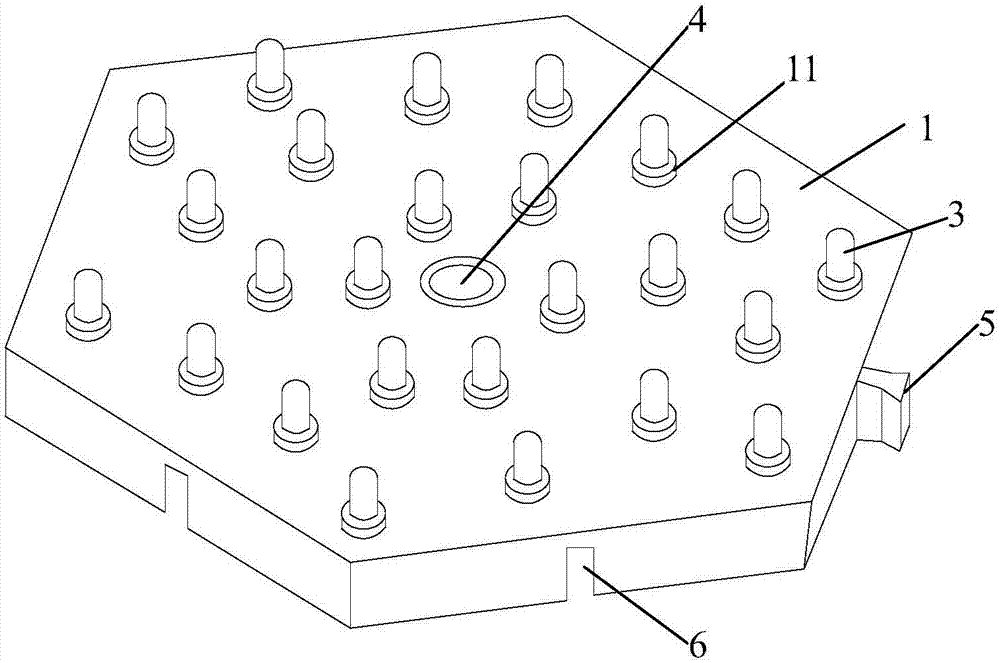

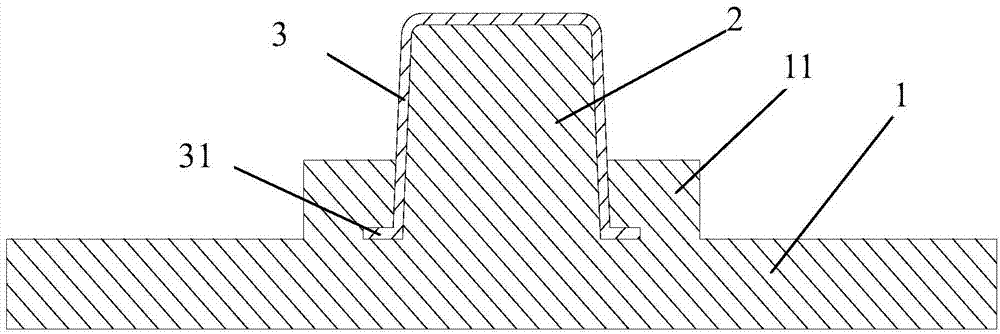

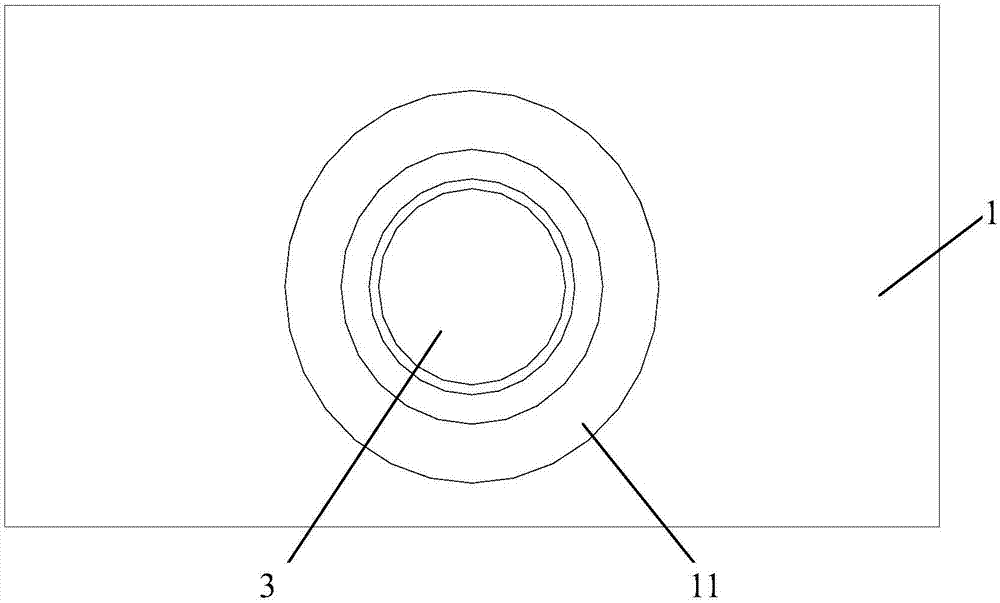

[0035] see Figure 1-Figure 3 , a dryland ski floor tile, comprising a ski floor tile body 1, a round head column 2 is arranged on the upper surface of the ski floor tile body 1, and the number of the round head column 2 is multiple, and a plurality of round head columns 2 are fixed with metal Set of 3. The metal sheath 3 is preferably made of stainless steel. The top of the metal sleeve 3 is a spherical curved surface with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com